Homework 9

Devin Gatherwright

11/14/2012

IET 307: Materials Science

HW 9 (based on chapter 16), Due by 11.55 PM, Tuesday, November 20’Th, 2012

100 points

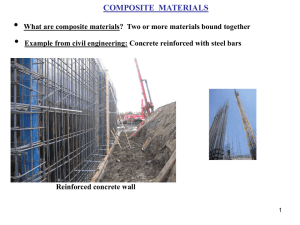

1. Give examples of applications where composites are used for load bearing applications. (5 points).

Answer: One example of a composite used for a load bearing application is reinforced concrete, which is essentially Portland cement concrete that is reinforced by the addition of steel rods, wires, or bars, which are embedded in the concrete material. The addition of these aforementioned materials enables reinforced concrete to support greater tensile, compressive, and shear stresses. Reinforced concrete is commonly and widely used in construction and in structural applications such as buildings.

Another example of a composite used for a load bearing application is the structural composite sandwich panel. According to the textbook, sandwich panels are lightweight panels or beams that possess relatively high stiffness and strength properties, and therefore can withstand both tensile and compressive stresses that result from applied loads. Sandwich panels are used for both floors and walls in structural applications such as buildings

2. What is a nano-composite? How can steels containing ferrite and martensite be described as composites? Explain. (5 points)

According to the textbook, nanocomposites are composites that are made of nanosized particles that are embedded in a type of matrix. Steel containing ferrite and martensite can be classified as composites due to the fact that composite materials are made up of two or more materials that have different chemical and physical properties from each other. Therefore, since ferrite and martensite are both non-metallic materials, combining them with steels would result in a composite.

3. What is a fiber-reinforced composite? What fiber-reinforcing materials are commonly used? In a fiber-reinforced concrete, what is the role of the matrix? (10 points)

Answer: According to the textbook, a fiber-reinforced composite can be defined as “a composite in which the dispersed phase is in the form of a form of a fiber, which is a filament that has a large length-to-diameter ratio.” Some examples of common fiber-reinforced composites are graphite, fiberglass, and Kevlar.

According to the textbook, the role of the matrix can be broken down into several different functions: first, it binds the fibers together and therefore acts as a type of medium by which an external stress is applied and distributed to the fibers, with a small proportion of the applied load be sustained by the matrix. Secondly, the matrix protects the individual fibers from surface damage that results from either chemical reactions with the environment, or mechanical abrasion. Lastly, the matrix separates the fibers prevents the propagation of brittle cracks from taken place from fiber to fiber, and therefore preventing failure.

4. Explain Pultrusion process in a paragraph and include a schematic diagram. (10 points)

Answer: According to the textbook, pultrusion is a process that is used to manufacture components that have continuous lengths and a constant cross-sectional shape. To begin this process, continuous fibers roving or tows are filled with a thermosetting resin, which are then pulled through a steel die that creates the desired shape and sets the resin/fiber ratio. This stock is then passed through a precision machined curing die that imparts the final shape. Furthermore, the die is heated, which creates the curing of the resin matrix. A pulling device then pulls the stock through the aforementioned dies and also sets the pace of the pultrusion process.

According to the textbook, hollow sections and tubes are created by utilizing center mandrels or inserted hollow cores. According to the textbook, commonly used matrix materials include polyesters, epoxy resins, and vinyl esters respectively.

The following is a diagram of the pultrusion process, taken from subtech.com:

5. Calculate (a) the modulus of elasticity, (b) the tensile strength, and (c) the fraction of the load carried by the fiber for the following composite material stressed under Isostrain conditions. The composite consists of a continuous glass-fiber-reinforced-epoxy resin produced by using 60% by volume of E-glass fibers having a modulus of elasticity of E f

= 10.5*10

6 psi, a tensile strength of

350, 000 psi and a hardened epoxy resin with a modulus of E m

= 0.45*10

6 psi and a tensile strength of 9000 psi. (Hint – See example problem 12.2 in your text book and associated equations before the problem) (20 points)

Answer:

𝐸 𝑐𝑙

= 𝐸 𝑚

× 𝑉 𝑚

+ 𝐸 𝑓

× 𝑉 𝑓

𝐸 𝑐𝑙

= (0.45 × 10 6 𝑝𝑠𝑖) × (0.4) + (10.5 × 10 6 𝑝𝑠𝑖) × (0.6)

𝐸 𝑐𝑙

= (180,000) + (6,300,000)

𝐸 𝑐𝑙

= 6.48 × 10

6 𝑝𝑠𝑖 𝑚𝑜𝑑𝑢𝑙𝑢𝑠 𝑜𝑓 𝑒𝑙𝑎𝑠𝑡𝑖𝑐𝑖𝑡𝑦 𝑖𝑠 6.48 × 10 6 𝑝𝑠𝑖 𝜎 ∗ 𝑐𝑙

= 𝜎

′ 𝑚

(1 − 𝑉 𝑓

) + 𝜎 ∗ 𝑓

𝑉 𝑓 𝜎 ∗ 𝑐𝑙

= 9,000 𝑝𝑠𝑖 (1 − 0.6) + (350,000 𝑝𝑠𝑖 × 0.6) 𝜎 ∗ 𝑐𝑙

= 3,600 + 210,000 𝜎 ∗ 𝑐𝑙

= 213,600 𝑝𝑠𝑖 𝑡𝑒𝑛𝑠𝑖𝑙𝑒 𝑠𝑡𝑟𝑒𝑛𝑔𝑡ℎ 𝑖𝑠 213,600 𝑝𝑠𝑖

𝐹 𝑓

=

𝐸 𝑚

𝐸 𝑓

× 𝑉 𝑓

× 𝑉 𝑚

+ 𝐸 𝑓

× 𝑉 𝑓

=

10.5 × 10 6 𝑝𝑠𝑖 × 0.6

0.45 × 10 6 𝑝𝑠𝑖 × 0.4 + 10.5 × 10 6 𝑝𝑠𝑖 × 0.6

=

6,300,000

180,000+6,300,000

=

6,300,000

6,480,000

. 9722 = 97.2 % 𝑜𝑓 𝑡ℎ𝑒 𝑙𝑜𝑎𝑑 𝑖𝑠 𝑐𝑎𝑟𝑟𝑖𝑒𝑑 𝑏𝑦 𝑡ℎ𝑒 𝑓𝑖𝑏𝑒𝑟.

6. What are hybrid composites? Give examples. Why is it better than single fiber type? (10 points)

Answer: According to the textbook, a hybrid composite can be defined as “a composite that is fiber reinforced by two or more types of fibers, such as glass or carbon.” According to the textbook, the two fibers can be aligned and mixed with one another, or layered with alternating fiber types. According to the textbook, hybrid composites are applied in material such as sporting goods, lightweight orthopedic components, and generally lightweight air transport structural components. Using two or different types of fibers is better than using just one because when the hybrid composite is under stress by tension, failure is not sudden to occur. According to the book, one fiber type (usually carbon) will be the first to fail, which then transfers the load to the other fiber type. In a single fiber type, once the fiber fails, then the material fails.

7. What is a honeycomb core sandwich panel? What are its advantages and how is it made? (10 points)

Answer: According to the textbook, sandwich panels can be defined as “a type of structural composite that consists of two or more stiff and strong outer faces that are separated by a lightweight core material.”

Honeycomb is one of the lightweight core materials used. According to the textbook, the honeycomb core is composed of thin foils that have been formed into interlocking cells. The material used for the honeycomb core of the sandwich panel can either be an aluminum alloy or an aramid polymer, according to the textbook.

Furthermore, according to the textbook, both the stiffness and strength of the honeycomb core structure can be attributed to the size of the cell, the cell wall thickness, and the material from which the honeycomb core is created. According to the textbook, sandwich panels such as the honeycomb core sandwich panel are used in applications that include roofs, floors, and wall of aircraft and buildings.

8. What are Aramid fibers? What types of chemical bonding takes place within the Aramid fibers?

What types of chemical bonding takes place between the Aramid fibers? How does the bonding affect their mechanical strength properties? (10 points)

Answer: According to the textbook, aramid fibers are high-modulus, high-strength materials that are known for their incredible strength-to-weight ratios, which are actually better than most metals. The type of bond that takes place between the aramid fibers is a hydrogen bond. According to the book, hydrogen bonds form between the adjacent chains that are aligned in the direction of the fiber. The chemical bond that takes place with the aramid fibers is a covalent bond because the electrons are being shared between the atoms in the fiber according to the schematic in the textbook. Mechanically, aramid fibers have longitudinal tensile

strengths and tensile moduli that are much higher than other polymeric fiber materials. However, aramid fibers are relatively weak in compression. Furthermore, aramid fibers are well-known for their toughness, resistance to creep, impact resistance, resistance to combustion, and are very flexible and somewhat ductile as a result of their bonds.

9. What is Portland cement? How is it made? What advantages and disadvantages does concrete offer as a composite material? (10 points)

Answer: According to the textbook, Portland cement is created by grinding and mixing clay and lime-bearing materials into correct proportions and then heating the mixture to around 1400 degrees Celsius in a rotary kiln, which produces changes in the physical and chemical makeup of the raw material. The resulting product is then ground up in a fine powder and a small amount of gypsum is added in order to retard the product, thus giving us giving us Portland cement as the finished product. The advantages of Portland cement are that it is known as hydraulic cement, meaning the hardness of the material develops by the addition of water, and is an excellent binding agent as well. The disadvantage of Portland cement is that the correct amount of water must be added to the cement to ensure optimum-ability; too little water results in incomplete bonding, and too much water results in excessive porosity. In either of these cases, the strength of Portland cement is downgraded considerably.

10. Original tennis rackets were made of natural wood. Nowadays, composite materials such as carbon-fiber-reinforced-epoxy are the material of choice for tennis rackets. Explain what properties are important in the design of a tennis racket frame. What are the advantages of the current materials used in the frame of the tennis racket? (10 points)

Answer: In my opinion, some important properties required for the design of a tennis racket are that the tennis racket should have a low density (in other words, lightweight) design; a tennis racket should be sturdy and not brittle, due to the fact that it comes in contact with an object, being a tennis ball; also, a tennis racket have some amount of impact strength in its design due to the aforementioned fact that it comes in contact with a tennis ball at certain speeds; and lastly, a tennis racket should be resistant to deformation over time from its environmental surroundings.

The advantages of using carbon-fiber-reinforced-epoxy as the material for a tennis racket are that it provides a good amount of strength while being relatively lightweight, which is perfect for the design of a tennis racket. Also, carbon-fiber-reinforced-epoxy is rigid in nature, meaning it is sturdy and not brittle, nor will it be easy to deform over time/use.

Works Cited

Diagram of pultrusion process taken directly from: http://www.substech.com/dokuwiki/doku.php?id=pultrusion