ENVIRONMENTAL SOLUTIONS WORLDWIDE INC

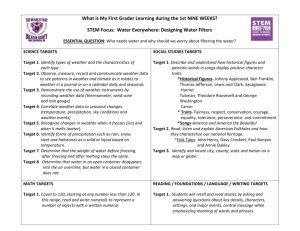

advertisement