Solicitud de Clasificación Ambiental

advertisement

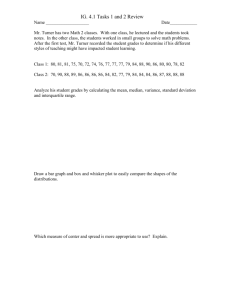

OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design SUMMARY - SURVEY OF CALCAREOUS DEPOSITS Stage 2 Final Report: Analysis of Superficial Samples and Drilling Plan Design OROSUR - NOLETIR Introduction In this document analytical results from 335 samples collected from PUNTAS DEL PARAO PROJECT. Analytical Results Sample A397v A399c A400c A401v A402v A403v A404c A405c A406v A407v A408c A409c A410c A411v A411c A412c2 A413c A414v A415v A416c A417v A418v A419c A419v A420c A421v A421c A422c A423c A424c A425c A426v A426c A427v A427c A429c A430v A430c A431c RIn 6.88 4.63 4.22 4.72 3.70 5.91 2.54 8.73 5.03 5.41 5.07 6.75 6.46 3.81 5.06 5.36 12.53 5.37 4.60 5.25 5.90 4.31 7.94 6.29 7.24 6.52 14.87 3.89 9.94 22.37 7.79 5.14 20.39 11.31 19.05 14.17 4.10 10.71 3.26 R2O3n 1.91 1.77 2.24 1.50 2.06 1.68 0.99 1.75 2.05 1.13 1.24 1.05 0.46 1.00 2.75 3.11 8.99 1.47 1.35 11.73 1.35 3.14 4.32 1.29 2.38 1.33 6.23 3.38 4.76 2.60 1.64 1.31 10.13 1.03 11.21 3.96 1.48 3.08 1.30 CaCO3n 86.11 90.09 91.24 88.60 89.90 90.17 93.51 86.52 88.81 84.31 91.26 85.23 85.91 90.52 90.91 89.26 74.71 88.22 87.39 80.94 87.51 86.18 84.50 85.64 87.34 86.44 76.77 91.16 80.26 71.14 82.91 88.12 53.66 84.91 50.00 76.15 90.78 80.64 93.32 MgCO3n 5.10 3.51 2.29 5.19 4.34 2.24 2.95 3.00 4.11 9.15 2.42 6.97 7.18 4.67 1.28 2.26 3.77 4.93 6.67 2.08 5.23 6.37 3.23 6.78 3.04 5.71 2.14 1.57 5.04 3.89 7.66 5.43 15.82 2.76 19.74 5.72 3.63 5.57 2.12 Cal-Ind no suitable suitable no no suitable suitable no no no suitable no no suitable suitable no no no no no no no no no no no no suitable no no no no no no no no suitable no suitable Cement suitable suitable suitable suitable suitable suitable suitable suitable suitable no suitable no no suitable suitable suitable no suitable no no suitable no no no suitable suitable no suitable no no no suitable no no no no suitable no suitable AC1 suitable suitable suitable suitable suitable suitable suitable suitable suitable no suitable suitable suitable suitable suitable suitable no suitable suitable no suitable suitable no suitable suitable suitable no suitable no no no suitable no no no no suitable no suitable OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design Sample A432v A433c1 A433c2 A435c A436c A437c A438c A439c A440v A441v A442v A443v A444v A445v A446v A446c A447c A448v A449v A450c A451c A452v A453v A454v A455v A456v A457c A458c A459c A460c A461v A464c A465c A467c A469c A471c A473c A474c A475c A476c A477c A478c A481c A482c A483c A488c A489c A491c A492c A493v A494c RIn R2O3n 1.55 1.33 1.85 0.84 3.24 2.49 9.18 2.43 4.30 1.35 9.73 9.71 2.11 1.41 2.85 1.37 2.35 1.20 2.03 1.01 4.62 1.69 2.16 1.28 4.58 1.93 3.84 1.40 2.92 1.57 2.54 1.23 2.44 1.14 3.92 1.14 3.48 2.13 9.36 1.34 2.13 1.09 10.04 1.44 5.41 1.52 1.99 1.01 2.30 0.87 0.88 1.93 5.32 1.94 11.01 2.28 15.14 3.16 7.25 1.56 2.85 2.22 6.03 1.33 6.21 1.79 5.26 2.30 2.73 0.85 3.62 1.31 3.88 1.16 4.51 1.54 8.60 2.22 9.57 3.22 2.41 0.83 8.75 1.43 9.77 1.03 11.82 1.36 4.42 1.06 8.94 0.90 4.52 1.44 4.38 1.42 3.90 0.58 5.60 1.78 2.47 0.67 CaCO3n 93.24 95.42 91.83 85.21 90.82 71.61 93.06 92.91 93.18 93.55 90.62 93.58 90.30 92.91 93.84 92.70 93.15 91.75 93.32 84.57 94.57 85.83 89.48 95.68 95.18 96.10 88.91 83.09 76.02 87.82 93.60 89.99 87.29 88.23 93.89 91.65 91.76 90.01 82.61 83.90 92.30 86.79 85.92 83.43 91.06 86.33 90.28 90.15 90.77 89.52 92.56 MgCO3n 3.87 1.88 2.43 3.18 3.53 8.95 3.42 2.87 3.27 3.42 3.07 2.98 3.18 1.86 1.67 3.53 3.27 3.19 1.06 4.74 2.22 2.69 3.59 1.32 1.65 1.09 3.83 3.62 5.68 3.36 1.33 2.66 4.71 4.21 2.54 3.42 3.20 3.94 6.57 3.31 4.45 3.04 3.29 3.39 3.46 3.82 3.75 4.05 4.75 3.11 4.29 Cal-Ind suitable suitable suitable no suitable no suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable no suitable no no suitable suitable suitable no no no no suitable no no no suitable suitable suitable suitable no no suitable no no no suitable no suitable suitable suitable no suitable Cement suitable suitable suitable suitable suitable no suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable no suitable suitable suitable suitable suitable suitable suitable no no suitable suitable suitable suitable suitable suitable suitable suitable suitable no no suitable suitable suitable no suitable suitable suitable suitable suitable suitable suitable AC1 suitable suitable suitable suitable suitable no suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable no suitable suitable suitable suitable suitable suitable suitable no no suitable suitable suitable suitable suitable suitable suitable suitable suitable no no suitable suitable suitable no suitable suitable suitable suitable suitable suitable suitable OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design Sample A495v A496c A499c A503c A506c A511c A512c A516c A517c A518v A519v A521c A522c A523c A524c A525c A526c A527c A529c A530c M779v M780c M781v M782c M783c M784c M785v M786v M787v M788c M789c M790c M791c M792v M794v M795c M796v M797v M798v M799v M800v M801v M802c M804v M805v M806v M807v M808v M809v M810c M811v RIn R2O3n 2.48 1.98 1.89 0.96 4.61 1.36 4.31 1.28 2.97 0.78 3.36 1.26 2.14 1.82 4.88 1.39 6.37 2.69 2.51 1.21 9.69 5.14 4.77 1.42 3.22 2.11 1.71 0.40 3.37 0.82 10.87 6.10 4.80 1.73 12.55 5.51 5.75 1.37 5.25 1.10 7.47 2.63 7.31 1.98 5.84 1.55 10.79 3.14 6.74 2.26 13.38 1.78 2.10 0.79 8.44 2.81 4.66 1.12 7.48 2.32 7.02 1.34 13.19 3.35 17.71 7.50 2.36 0.80 5.92 1.68 14.28 2.50 5.32 1.42 2.68 1.50 7.78 1.51 1.63 0.69 3.15 0.89 5.26 1.08 9.63 2.66 2.28 0.87 4.02 1.33 1.47 1.01 2.23 0.90 2.21 0.59 2.36 0.85 12.11 0.92 4.49 1.19 CaCO3n 93.75 93.38 88.81 90.25 92.20 90.75 83.83 87.76 85.27 94.24 82.46 87.83 82.51 91.24 89.48 71.37 83.62 75.86 87.16 87.86 87.45 88.95 91.21 82.03 85.93 79.67 95.88 83.36 91.20 81.83 87.11 77.20 65.06 95.62 89.25 78.89 89.57 90.37 87.17 94.48 92.21 88.25 79.30 94.66 91.48 95.15 94.19 94.66 94.60 84.21 91.61 MgCO3n 1.79 3.77 5.23 4.16 4.05 4.63 12.21 5.97 5.67 2.04 2.71 5.98 12.16 6.65 6.33 11.66 9.85 6.07 5.72 5.80 2.44 1.76 1.41 4.04 5.07 5.16 1.23 5.39 3.02 8.36 4.53 6.26 9.73 1.22 3.15 4.33 3.70 5.45 3.54 3.20 3.75 5.40 8.41 2.19 3.17 2.37 2.68 2.54 2.19 2.76 2.71 Cal-Ind suitable suitable no suitable suitable suitable no no no suitable no no no suitable no no no no no no no no suitable no no no suitable no suitable no no no no suitable no no no suitable no suitable suitable no no suitable suitable suitable suitable suitable suitable no suitable Cement suitable suitable suitable suitable suitable suitable no suitable suitable suitable no suitable no no no no no no suitable suitable suitable suitable suitable no suitable no suitable no suitable no suitable no no suitable suitable no suitable suitable suitable suitable suitable suitable no suitable suitable suitable suitable suitable suitable no suitable AC1 suitable suitable suitable suitable suitable suitable no suitable suitable suitable no suitable no suitable suitable no no no suitable suitable suitable suitable suitable no suitable no suitable no suitable no suitable no no suitable suitable no suitable suitable suitable suitable suitable suitable no suitable suitable suitable suitable suitable suitable no suitable OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design Sample M812v M813c M814v M815c M816c M817v M818c M819v M820c M821v M822v M823c M824v M825v M826c M827v M828c M829v M830c M831v M832c M833c M834c M835c M836c M837c M838v M839c M840c M841v M842v M844c M845v M846c M847c M848c M849v M850v M851c M853v2 M854v M855v M856v M857v M858v M859c M860v M861c M862c M863v M865v RIn R2O3n 2.20 0.91 4.02 1.39 7.20 2.25 4.05 1.23 1.55 2.15 1.36 0.71 3.42 1.59 1.95 1.03 2.85 1.06 2.34 0.88 3.49 0.96 1.72 2.02 3.07 0.86 2.16 1.08 1.35 0.86 1.58 1.50 3.85 1.24 1.57 1.39 5.18 1.47 3.33 2.40 5.23 1.80 4.92 1.63 8.54 0.85 7.43 0.94 2.73 4.17 4.92 0.80 6.95 2.07 5.73 1.25 5.55 1.15 9.68 2.83 3.62 3.50 4.21 1.59 6.03 1.69 4.29 1.55 3.68 1.14 1.76 0.76 1.68 2.10 10.71 8.53 10.76 2.12 6.13 1.81 3.37 2.17 3.84 2.35 7.16 4.02 4.28 2.08 13.36 3.45 9.46 4.04 19.79 7.90 6.35 3.10 5.28 1.43 4.16 0.98 8.25 2.21 CaCO3n 94.81 91.37 87.47 93.31 94.72 95.27 92.68 93.92 94.41 94.41 92.41 93.71 92.99 94.74 96.74 94.51 92.72 93.76 90.97 90.82 90.41 91.08 85.93 86.80 91.08 92.47 86.44 89.24 78.98 76.92 88.41 88.68 88.27 91.09 91.72 96.91 93.08 73.84 81.48 89.46 91.95 91.08 83.75 89.56 79.76 79.30 66.33 84.11 89.22 91.89 88.39 MgCO3n 2.08 3.21 3.08 1.41 1.58 2.67 2.31 3.10 1.68 2.37 3.14 2.55 3.08 2.01 1.05 2.41 2.19 3.27 2.38 3.44 2.55 2.37 4.67 4.83 2.02 1.81 4.53 3.77 14.31 10.58 4.47 5.52 4.00 3.08 3.47 0.58 3.15 6.92 5.64 2.60 2.50 2.73 5.07 4.08 3.42 7.20 5.98 6.44 4.07 2.97 1.15 Cal-Ind suitable suitable no suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable no no suitable suitable no no no no no no no suitable suitable suitable suitable no no no suitable suitable no no no no no no no suitable no Cement suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable no no suitable suitable suitable suitable suitable suitable suitable no no suitable suitable suitable no suitable no no no no suitable suitable suitable AC1 suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable no no suitable suitable suitable suitable suitable suitable suitable no no suitable suitable suitable no suitable no no no no suitable suitable suitable OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design Sample M866c M867c M868v M869v M870c M871v M872c M873v M874c M875c M876c M878c M879c M880c M881v M882c M883v M884v M885c M888c M889c M892c M893c M894v M895v M896c M897v M898c M899c M900c M901c M902v M903c M904v M905c M906c M907v M908v M909v M910c M911c M912c M913c M914c M916c M918c M919c M920c M921c M923c M924c RIn R2O3n 9.92 3.32 3.20 2.40 3.96 1.07 6.31 2.44 2.60 1.90 2.45 0.93 16.63 2.22 3.93 0.62 1.71 2.79 7.97 2.78 37.69 12.79 15.19 3.62 4.38 2.59 4.57 1.74 2.55 1.01 5.79 2.18 5.69 1.80 3.19 1.04 9.53 2.48 12.34 1.79 7.18 2.24 4.32 2.39 4.67 2.08 3.01 1.24 3.14 1.01 2.40 2.38 2.94 0.94 12.54 5.77 3.12 3.20 2.15 0.52 4.56 0.87 4.79 1.46 7.40 1.99 9.87 3.37 18.53 2.61 8.55 2.01 2.34 0.77 9.96 4.48 8.52 1.49 4.72 1.44 2.69 0.87 3.84 1.36 2.32 1.15 15.14 2.66 10.64 1.79 12.64 1.27 5.26 1.03 5.59 0.68 5.19 0.84 4.44 1.84 3.04 1.39 CaCO3n 78.54 92.01 91.89 88.90 91.71 93.93 78.73 94.52 91.27 81.38 41.67 72.11 89.55 91.17 93.05 86.32 89.78 91.86 79.08 80.44 85.16 91.24 88.62 90.24 92.67 91.50 92.75 71.38 91.03 94.84 93.73 87.86 55.38 80.85 71.44 84.97 92.11 75.11 85.33 90.71 65.60 83.34 93.17 71.18 80.68 76.35 90.89 89.96 90.61 86.62 92.69 MgCO3n 8.22 2.40 3.08 2.35 3.80 2.69 2.42 0.93 4.23 7.87 7.85 9.09 3.48 2.51 3.39 5.71 2.72 3.91 8.91 5.43 5.42 2.05 4.63 5.51 3.18 3.72 3.36 10.32 2.65 2.48 0.85 5.90 35.23 5.91 7.42 4.46 4.78 10.46 4.67 3.14 30.84 11.45 3.36 11.02 6.89 9.73 2.81 3.77 3.35 7.10 2.87 Cal-Ind no suitable suitable no suitable suitable no suitable suitable no no no no suitable suitable no no suitable no no no suitable no suitable suitable suitable suitable no suitable suitable suitable no no no no no suitable no no suitable no no suitable no no no suitable no suitable no suitable Cement no suitable suitable suitable suitable suitable no suitable suitable no no no suitable suitable suitable suitable suitable suitable no no suitable suitable suitable suitable suitable suitable suitable no suitable suitable suitable suitable no no no no suitable no suitable suitable no no suitable no no no suitable suitable suitable no suitable AC1 no suitable suitable suitable suitable suitable no suitable suitable no no no suitable suitable suitable suitable suitable suitable no no suitable suitable suitable suitable suitable suitable suitable no suitable suitable suitable suitable no no no no suitable no suitable suitable no no suitable no no no suitable suitable suitable suitable suitable OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design Sample A583c A584c A585c A586c A587c A588v A589c A590c A591c A592c A593v A594c A595c A596v A597v A598c A599c A600v A601v A602c A603c A604c A605c A606c A607v A608c A609v A610c A611c A612c A613c A614v A615v A616c A617v A618c A619v A620v A621c A622c A623v A624v A625c A626v A627c A628v A629c A630v A632v A633v A634v RIn R2O3n 3.53 2.57 2.33 2.05 4.55 2.72 4.07 2.83 2.72 1.72 3.51 2.32 4.00 2.50 3.75 1.28 5.19 1.60 7.28 1.56 3.81 1.03 4.02 1.87 6.86 4.24 6.22 1.14 6.89 1.03 5.05 1.88 1.92 1.04 2.24 1.54 3.61 1.01 4.66 0.74 2.34 0.78 15.07 1.88 6.24 2.11 4.63 1.23 2.66 1.39 6.48 1.95 8.20 4.91 10.76 2.36 5.02 1.58 5.32 1.55 1.59 1.55 0.10 1.23 2.26 2.80 6.13 2.08 4.76 2.08 1.72 1.93 1.59 1.81 3.22 1.64 4.79 2.29 10.16 2.40 2.12 1.36 2.86 2.14 2.13 1.74 3.42 1.81 10.56 1.87 3.30 1.28 10.52 1.94 6.86 2.87 3.61 2.58 3.54 3.06 2.72 3.76 CaCO3n 88.37 71.32 87.06 86.61 93.42 91.17 88.21 91.25 88.77 87.08 90.87 87.80 70.34 85.65 84.81 86.50 90.65 89.30 89.64 91.02 89.39 80.22 87.87 93.06 94.53 89.27 83.62 83.83 91.51 91.52 93.74 97.96 93.08 88.63 89.39 94.52 93.66 92.73 89.71 85.01 94.57 90.60 95.19 91.88 85.07 93.30 84.17 85.55 88.81 88.23 87.79 MgCO3n 5.53 24.30 5.67 6.48 2.14 3.01 5.29 3.72 4.44 4.08 4.29 6.32 18.55 7.00 7.26 6.58 6.40 6.91 5.74 3.57 7.48 2.82 3.78 1.08 1.42 2.30 3.27 3.04 1.90 1.61 3.13 0.70 1.86 3.16 3.77 1.83 2.94 2.41 3.22 2.43 1.96 4.39 0.93 2.88 2.51 2.13 3.38 4.72 5.00 5.17 5.73 Cal-Ind no no no no suitable suitable no suitable no no suitable no no no no no suitable no no suitable no no no suitable suitable no no no suitable suitable suitable suitable suitable no no suitable suitable suitable no no suitable suitable suitable suitable no suitable no no no no no Cement suitable no suitable no suitable suitable suitable suitable suitable suitable suitable no no no no no no no suitable suitable no no suitable suitable suitable suitable no no suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable no suitable suitable suitable suitable AC1 suitable no suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable no suitable no suitable suitable suitable suitable suitable suitable no suitable suitable suitable suitable no no suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable no suitable suitable suitable suitable OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design Sample M151v M152c M153c M154v M155v M156c M157c M158c M159v M160c M161v M162v M163v M164v M165v M166v M167c M168c M169c M170c M171c M172c M173v M174c M175v M176c M177c M178c M179c M181c M182c M183c M184v M185c M186v M187c M188c M189c M190v M191c M192v RIn R2O3n 5.07 1.19 2.43 0.51 5.98 1.97 1.67 1.85 1.74 1.54 4.94 2.14 4.78 5.84 10.36 4.02 5.08 2.26 3.86 1.32 1.91 1.65 2.68 2.66 2.43 2.24 5.74 0.90 3.52 1.03 4.27 3.19 5.62 2.60 3.75 1.42 2.13 1.38 3.77 1.62 6.91 1.14 8.10 2.86 5.82 1.73 3.38 1.94 4.08 2.32 1.85 1.55 1.48 0.81 7.10 2.27 3.60 1.47 3.68 1.33 5.31 5.27 5.20 1.39 4.34 1.29 3.68 1.62 1.98 1.79 1.64 0.87 5.19 2.73 6.51 1.67 3.38 1.28 7.30 3.18 4.24 1.38 CaCO3n 89.36 94.16 86.38 93.93 94.08 87.92 83.47 80.53 89.45 93.19 93.69 91.37 93.06 90.55 93.46 90.50 85.60 91.94 92.32 90.68 88.81 85.51 89.20 90.67 89.07 95.07 94.87 88.80 91.92 92.31 86.89 90.29 90.13 92.40 93.04 95.05 88.15 89.47 92.50 85.33 91.13 MgCO3n 4.37 2.89 5.67 2.55 2.63 5.00 5.91 5.09 3.20 1.64 2.74 3.30 2.28 2.81 2.00 2.05 6.17 2.89 4.18 3.93 3.14 3.52 3.24 4.01 4.53 1.53 2.84 1.84 3.01 2.67 2.53 3.12 4.24 2.30 3.20 2.44 3.93 2.35 2.84 4.18 3.24 Cal-Ind no suitable no suitable suitable no no no no suitable suitable suitable suitable suitable suitable suitable no suitable suitable suitable no no no suitable no suitable suitable no suitable suitable no suitable suitable suitable suitable suitable no no suitable no suitable Cement suitable suitable suitable suitable suitable suitable no no suitable suitable suitable suitable suitable suitable suitable suitable no suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable AC1 suitable suitable suitable suitable suitable suitable no no suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable suitable Values presented on the table attached are: Sample: name of the sample collected in the field; UTMx/UTMy: plain coordinates in UTM system (Sector 21S) with WGS84 datum RI: insoluble waste in percentage, normalized to 100% R2O3n: generic oxide (iron, manganese, etc.) in percentage, normalized to 100% CaCO3n: calcium carbonate in percentage, normalized to 100% MgCO3n: magnesium carbonate in percentage, normalized to 100% Cal-Ind: Indicates if the sample is suitable for industrial lime (CaCO3n >= 90%) OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design Cement: indicates if the sample is suitable for Portland cement (CaCO 3n >= 85% & MgCO3n <= 6%) AC1: indicates if the sample is suitable for agricultural use (energetic control of pH: CaCO3n >= 85%) The descriptive statistic for each parameter is presented next: Calcium Carbonate CaCO3 - Descriptive Mean Deviation Typical Error Median Deviation Mode Standard Deviation Sample Variance Kurtosis Asymmetry Coefficient Rank Minimum Maximum Adding Calculation CaCO3n - Descriptive 88.79 0.432 90.18 92.7 7.90 62.544 6.96 -2.01 59.75 43 102.75 29745.2 335 Mean Deviation Typical Error Median Deviation Mode Standard Deviation Sample Variance Kurtosis Asymmetry Coefficient Rank Minimum Maximum Adding Calculation 87.91 0.392 89.64 #N/A 7.18 51.496 9.63 -2.51 56.29 41.67 97.96 29449.3 335 80 100% 70 90% 80% 60 70% 50 60% 40 50% 30 40% 30% 20 20% 10 10% 0 0% <=80 82 84 86 88 90 92 94 96 98 100 Clase Distribución de los valores de CaCO3n analizados. The medium value of CaCO3n is 87.9 ± 7.2%. There are 264 analytical values with numbers over 85% and 162 values over 90%. CaCO3n distribution is showed in the picture attached. Carbonate mineralization is concurrent with the regional structure appearing like an open North-South fold and hinge dipping to the North. The base of the sequence would be located at the South and the top in the northern area. OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design MgCO3n medium value is 4.4 ± 3.4%. There are 324 analytical values with numbers above 6%. MgCO3n distribution is shown in the histogram attached. Magnesium carbonate MgCO3 - Descriptive Mean Deviation Typical Errror Median Deviation Mode Standard Deviation Sample Variance Kurtosis Asymmetry Coefficient Rank Minimum Maximum Adding Calculation MgCO3n - Descriptive 4.46 0.19 3.5 3.5 3.57 12.72 24.09 4.09 32.21 0.57 32.78 1493.1 335 Mean Deviation Typical Error Median Deviation Mode Standard Deviation Sample Variance Kurtosis Asymmetry Coefficient Rank Minimum Maximum Adding Calculation 4.40 0.19 3.42 #N/A 3.56 12.71 29.09 4.46 34.65 0.58 35.23 1472.95 335 100 100% 90 90% 80 80% 70 70% 60 60% 50 50% 40 40% 30 30% 20 20% 10 10% 0 0% 0 1 2 3 4 5 6 7 8 9 10 y mayor... Clase Distribution of MgCO3n values analyzed. Superficial analysis is coherent with the geological structure analyzed. The sides of the fold have the lowest values of magnesium carbonate and the highest of calcium carbonate. As it can be seen in the area where interpolation of analytical information can be considered valid, there are more than 308 hectares with MgCO3 concentration of less than 6% in weight, fulfilling requirements for Portland cement making. OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design Insoluble Waste RI - Descriptive RIn - Descriptive 5.71 0.23 4.64 5.50 4.17 17.41 13.32 2.68 38.80 0.10 38.90 1914.44 335 Mean Deviation Typical Error Median Deviation Mode Standard Deviation Sample Variance Kurtosis Asymmetry Coefficient Rank Minimum Maximum Adding Calculation Mean Deviation Typical Error Median Deviation Mode Standard Deviation Sample Variance Kurtosis Asymmetry Coefficient Rank Minimum Maximum Adding Calculation 5.63 0.22 4.60 #N/A 4.07 16.57 12.78 2.64 37.59 0.10 37.69 1887.39 335 120 100% 90% 100 80% 70% 80 60% 60 50% 40% 40 30% 20% 20 10% 0 0% 0 2 4 6 8 10 12 14 16 y mayor... Clase Distribution of RIn values analyzed. R2O3 R2O3 - Descriptive Mean Deviation Typical error Median Deviation Mode Standard Deviation Sample Variance Kurtosis Asymmetry coefficient Rank Minimum Maximum Adding Calculation R2O3n - Descriptive 2.08 0.09 1.60 1.90 1.67 2.80 15.52 3.48 12.80 0.40 13.20 697.99 335 Mean Deviation Typical error Median Deviation Mode Standard Deviation Sample Variance Kurtosis Asymmetry coefficient Rank Minimum Maximum Adding Calculation 2.06 0.09 1.60 #N/A 1.65 2.72 15.32 3.48 12.39 0.40 12.79 690.36 335 OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design Reserves Calculation By estimation of resources we mean determining the amount of row material in a deposit or in one of its parts. This formal quantification of mineral raw material estimated by empirical or theoretical procedures is called Mineral inventory which is expressed in terms of resources and reserves. Resources estimation is an end for each stage of mineral deposits prospection and exploration works and this process continues during the exploitation of the deposit. All exploration works in a deposit contribute to a more precise estimation of mineral raw material. The estimation of resources/reserves is considered an ongoing process starting with exploration and the collection of information followed by geological interpretation and resources estimation. Later, modifying factors are considered (mining, metallurgical, environmental, legal, etc.) and the reserves estimate is calculated. The amount of reserves in a deposit, as one of the factors determining its economical feasibility, has a big influence in the deposit’s useful life, its annual production and the final decision to build the mining company. The different methods used at present for resource estimation are defined by the interpretation principles used and spatial interpolation techniques. This way the classical methods of calculation developed and used from the beginning of mining up to the present are obtained, based on manual procedures where the main parameters are estimated from the arithmetic mean deviation and adjusted mean deviation. On the other hand there are methods assisted by computers including the adjustment method by adjustment of the distance inverse and geostatistics fundamented in mathematical interpolation procedures defined from spatial information in the data. Traditional categorization methods use the following criteria: a) Geological continuity: The classification of resources and mineral reserves depends on the understanding of the deposit origin and the appreciation of the geological continuity of the volume mineralized. It is very important to establish here the physical continuity or geometry of the mineralization or of the controlling structures. Physical or geometrical continuity is not easily quantifiable. To Establish this type of continuity it is necessary to analyze data available and establish the deposit’s geological model on the grounds of the existing knowledge and previous experience from similar deposits; b) Density of the exploration net (study grade): For the different categories a determined spacing from the exploration net is recommended which depends on the type of deposit. Nets for each category are considered on the base of experience (analogy principle) and other similar deposits; c) Interpolation versus extrapolation: Blocks whose values have been estimated through interpolation (they are inside the sampling net) are classified in more reliable categories than those beyond the last line of shafts (extrapolated). Most classification systems require not including extrapolated blocks in the measured resources class; OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design d) Technological aspects: Includes certain aspects that can be used to discriminate or reject a resource in a given category. As an example, the presence of damaging elements which make good recovery impossible or make extraction of the useful component during the extraction process expensive. En el caso que nos ocupa quedan definidas por los cortes típicos para el uso de rocas calcáreas en general: For industrial use lime: CaCO3 >= 90 For Portland Cement: CaCO3 >= 85 & MgCO3 <= 6 For agricultural use: C1 ( pH energetic control) CaCO3 >= 85 For agricultural use: C2 (pH residual control) MgCO3 >= 30 (citrus, primor, etc.) As industrial use Dolomites: MgCO3 >= 35 & RI <= 8 & R2O3 < 1 e) Information quality: drill core recovery, the volume of samples, the form they were collected and the drilling method influence directly the quality of the information. Areas where there are reliability or representation problems in analysis must be excluded from the measured resource category. Geostatistic methods are considered the most trustable as they reflect – mainly – the amount and quality of information used to assess reserves. These diagrams were generically called geostatistics classifications as they are based on Kriging variance. In this sense Geostatistics is recommended as a valid and trustable procedure in most classification systems, becoming a standard in mineral resources estimation. The code proposed by the ONU, for example, proposes the use of geostatistics to classify resources as it makes it possible to identify quickly resources categories and mineral reserves (UN-ECE,1996). The variogram makes it possible to quantify the continuity or correlation level among the samples in a given mineralized area. The grade of this correlation has been frequently used to classify resources and reserves. Froidevaux (1982) recommended 3 types of classification: Blocks in the sampled area located inside the influence radius defined by the variogram´s scope; Blocks in the sampled area located beyond the influence radius defined by the variogram´s scope; Blocks inside the deposit located at a big distance from shafts (including extrapolated blocks). Typically, two focuses have been used to classify resources using the variogram. The first is based on an arbitrary subdivision of the scope observed. For example, all estimated blocks with a minimum number of samples located inside a determined influence radius could be classified as measured resources while all estimated blocks with a minimum number of samples found beyond the influence radius will be classified as indicated. In the second focus, resources categories are based on the plateau’s values. For example, blocks in a variogram area corresponding to 2/3 of the value of the Plateau can be classified as average, the ser are indicated. OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design Kriging allows obtaining, besides the value estimation of a block, an indication of the local precision through Kriging variance (Vk). From the beginning of Kriging development Vk has been used to determine the estimation’s trust intervals. For this reason it is necessary to assume that it adjusts to a normal or log normal model. However, it is strange in practice that estimation mistakes are subordinated to these distribution models. As for the calculation of Kriging variance only the configuration of the samples in space and not their local values is used, it must not be interpreted as a local variability measure. On the other hand Vk is calculated from the deposit’s average variogram; it is not only a sign of spatial disposition of the samples but also characterizes global average variances allowing discrimination among classes or resources categories. According to Valente (1982), percentage error in the estimation of the average, for a Group of n estimated blocks for a 95 % de probability can be calculated by the expression: 𝜀𝑘 = 200 √∑𝑛𝐼=1 𝜎 2 ∑𝑛𝐼=1 𝑡𝑘𝑖 Where tki and 2 are estimated values for Kriging and Kriging variance of each of the blocks. Reserves classification from the use of Kriging error from the average. Reserve Measure Indicated Inferred Average Error Kriging 20% 20% - 50% 50% With the concepts exposed Voronoi polygons were created for calcium carbonate contents and magnesium carbonate at 100% in the Pictures attached. Cuts were done every 2% for CaCO3 in interval 86 – 92% and for MgCO3 in interval 4 – 8%. The areas analyzed were calculated for all those polygons with Kriging error of the average inferior to 20% (measured reserves) and an interval of greater trust to 80% (proven reserves according to Diehl & David, 1982). The calculation of reserves volumes is considered proven for the first 5 meters of depth and potential up to 15 meters. From there on they are potential and even inferred, until getting the results of the drilling plan. OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design Reserves (Mton in bank) CaCO3(n) <86.00% 86.01-88.00% 88.01-90.00% 90.01-92.00% >92.00% Area (m2) 624745 523821 826522 1141998 554561 5m 9.06 7.60 11.98 16.56 8.04 10m 18.12 15.19 23.97 33.12 16.08 15m 27.18 22.79 35.95 49.68 24.12 30m 54.35 45.57 71.91 99.35 48.25 50m 90.59 75.95 119.85 165.59 80.41 >90.00% 1696559 24.60 49.20 73.80 147.60 246.00 At 5 meters depth, 24.6 million tones in caliches bench with more than 90% of calcium carbonate as measured and proved reserves are defined. Potential reserves with higher certainty (trust = 75% ± 5%) are established in 49.2 million tones in bench. Potential reserves with less certainty (trust = 60%) reach 73.8 million caliches tones with more than 90% of CaCO3. MgCO3(n) Area (m2) 5m Reserves (Mton in bank) 10m 15m 30m 50m <4.00% 4.01-6.00% 1995489 1021987 28.93 14.82 57.87 29.64 86.80 44.46 173.61 88.91 289.35 148.19 6.01-8.00% >8.00% 335050 319123 4.86 4.63 9.72 9.25 14.57 13.88 29.15 27.76 48.58 46.27 <6.00% 3017476 43.75 87.51 131.26 262.52 437.53 Considering exclusively the content of magnesium carbonate, 43.75 million tones are defined in reserves bench measured and proved at a 5 meters depth with content inferior to 6% of this component. Potential reserves reach 87.51 and 131.26 million tones in bench according to the two trust intervals defined for CaCO3. As it can be seen, magnesium carbonate is not the discriminator component to use caliches limestone as raw material for Portland cement, but the content of calcium carbonate. Condition CaCO3 ≥ 90.00% & MgCO3 ≤ 6% CaCO3 ≥ 90.00% & MgCO3 ≤ 4% Reserves (Mton in bank) 10m 15m 30m Area (m2) 5m 50m 1681578 24.38 48.77 73.15 146.30 243.83 504678 7.32 14.64 21.95 43.91 73.18 In the attached chart there are reserves calculations for polygons complying with conditions to make Portland cement in two situations: magnesium carbonate inferior to 6% (maximum acceptable) and inferior to 4%. OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design Proved reserves measures are about 24.38 million tones in bench for a 5 meters depth (90/6) and 7.32 million tones in identical conditions for 90/4. Potential reserves vary from 14.64 to 73.15 million tones in bench. Top reserves can reach 240 million tones in the bench. There was no deduction on the values exhibited regarding operations, logistics/strategy and/or environment. Design of Drilling Plan Es expressed in this document, the geological structure of the solid metacalcareous is defined as an open fold with dip to the North and vertical hinge. The floor of the sequence is in the South while the top (conglomerates from Barriga Negra Formation) are in the North. Both sides show the best conditions as raw material for Portland cement making for its content in calcium carbonates and magnesium. Considering the aforementioned, two areas are defined as top interest areas to be exploited, one in each side of the fold. In each one of them a profile was established where drillings sloping to 60°South, with a 50 meters depth each of them will be made. Profile #1 is in the western side and has 13 drillings along a SW-NE direction line. Profile #2 is in the Eastern side, with 7 drillings in a SSW-NNE direction line. Each drilling´s location is shown in the picture attached and s given by its UTM coordinates. Drillings will be executed through rotation with Diamond bit, extracting cores diameter NQ (47.6mm), BTW-C (42.0mm) or NTW-C (56.0mm) organized in wooden boxes specially built with that purpose. Every drilling will be described from structural and composition point of view and recorded through photographs. In calcareous consolidated areas three meters long samples will be taken cutting the core in half and one of the halves in two quarters. One of the quarters will be analyzed and the other will be kept in bags as backup. OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design Drilling NQ as those proposed here. Complete drilling, described and ready for sampling. These drillings will make it possible to know the distribution of carbonates in depth (magnesium and calcium) and define tendencies in “z” axis. In geological cuts attached there are tendencies in North – South direction, showing that CaCO3 content diminishes from South to North opposite to what happens with MgCO3. OROSUR – NOLETIR Summary - Survey of Calcareous Deposits Stage 2 Final Report – Analysis of Superficial Samples and Drilling Plan Design In this first drilling stage along specific profiles the aim is to find out if calcareous mineralization (in terms of flair for the purposes planned, especially as consumables for Portland cement making) has a stratabound structure as on the surface. It must be considered that this situation is not common in deposits of metamorphic calcareous Rocks in Uruguay, as in most cases trends or spatial behaviors can not be defined agreeing with the local regional structure.