SITE WORK

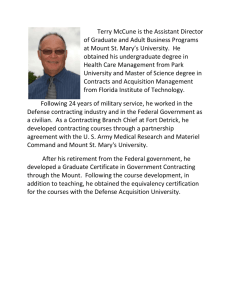

advertisement

Agriculture and Rural Development Program Rehabilitation of Kfarshima Laboratory SITE WORK ________________________________________________________________ 2 SELECTIVE DEMOLITION _________________________________________________________ 2 A. B. C. D. E. F. G. Scope ____________________________________________________________________________ 2 Description of work _________________________________________________________________ 2 Requirements of regulatory agencies ___________________________________________________ 2 Submittals ________________________________________________________________________ 2 Protection ________________________________________________________________________ 2 Materials _________________________________________________________________________ 2 WORKMANSHIP ___________________________________________________________________ 3 EXCAVATION & EARTHWORK______________________________________________________ 6 A. Scope ____________________________________________________________________________ 6 B. Performance and Standards _________________________________________________________ 6 C. Related Items ________________________________________________________________________ 6 D. Submittals ________________________________________________________________________ 6 E. Product Handling __________________________________________________________________ 7 F. Materials _________________________________________________________________________ 7 G. Workmanship _____________________________________________________________________ 7 ASPHALTIC CONCRETE PAVING ___________________________________________________ 11 A. B. C. D. E. Scope ___________________________________________________________________________ 11 Performance and Standards ________________________________________________________ 11 Materials ________________________________________________________________________ 11 Workmanship ____________________________________________________________________ 11 Lane Markings ____________________________________________________________________ 12 Site Works-Page 1 Agriculture and Rural Development Program Rehabilitation of Kfarshima Laboratory SITE WORK SELECTIVE DEMOLITION A. Scope Work includes all labour, materials and equipment, and performance of all operations related to demolition as indicated, required and specified. B. Description of work Refer to Drawings, and BOQ. C. 1. 2. Requirements of regulatory agencies Comply with applicable codes and regulations of local authorities, utility companies and governing bodies having jurisdiction. Regulatory Requirements D. Submittals Submit schedule of demolition showing proposed methods, procedures and sequence of demolition to the Contracting authority for review prior to beginning work. Demolition work shall not be commenced before obtaining the written approval of the Contracting authority. E. Protection Existing work to remain shall be protected from damage by means of barricades, planking or other approved means. 1. Contractor shall be responsible for devising methods of protection. 2. Contractor shall be liable for all damage to existing construction beyond that required to accomplish the work under this Contract. 3. Maintain and leave protection in place until surface protected is no longer subject to damage by construction operations. 4. Contractor shall pay special attention to the existing supporting columns while demolishing internal & external wall partitions. 5. Contractor shall provide protection to the existing concrete slabs while performing opening holes for electrical & mechanical facilities. F. 1. 2. Materials All materials resulting from demolition shall be removed from the site to a location directed by the Contracting authority. The use of explosives is strictly forbidden. Site Works-Page 2 Agriculture and Rural Development Program Rehabilitation of Kfarshima Laboratory G. 1. 2. 3. WORKMANSHIP Preparation a. Inspect existing conditions prior to beginning demolition to determine surfaces and construction which may be subject to damage. b. Review surfaces and construction, and proposed bracing, shoring and protection measures with Contracting authority prior to beginning demolition. 1. Provide shoring, bracing or support to prevent movement, settlement or collapse of work to be demolished and adjacent improvements to remain. 2. Provide structural shoring where necessary to transfer the load prior to demolition and maintain until work to existing structure is complete. 3. Provide protection at corners, projecting features and similar items prior to demolition and maintain until threat of damage has ceased. Use substantial boarding securely anchored and properly maintained. c. Provide temporary enclosures and employ other approved methods to limit amount of dust and dirt dispersed into the atmosphere. d. Provide all plant, scaffolding, gangways, etc... for the proper execution and protection of the works and roadways and footpaths. e. Demolition work is to be carried out in such a manner as to cause the minimum possible inconvenience to adjoining Building sector 1. All rubbish and debris and the works where necessary are to be sprinkled with water to prevent dust arising and screens and protection to the satisfaction of the Contracting authority. Demolition a. Proceed with demolition in systematic manner from top down. Complete demolition work above each floor before disturbing supporting members at floor below. b. Exercise care not to overload structure. 1. Shoring shall bear on suitably supported surfaces. 2. Locate demolition equipment and demolished materials throughout structure and remove as soon as possible so as not to impose concentrated or excessive loads. 3. Remove masonry in small section and lower to ground with hoists, pulleys or cranes which will avoid impact or shock to structure. c. Remove all work in ways which will prevent damage to other work, and will facilitate proper patching and repair. 1. Cut materials with power driven saw in neat, workmanlike fashion. Avoid excessive vibration to work to remain. 2. Shore and brace floor slabs, where-ever advisable to assure structural adequacy of affected work. Noise and speed Perform demolition and removals as quietly as practicable and with deliberate speed once demolition work has begun. Site Works-Page 3 Agriculture and Rural Development Program Rehabilitation of Kfarshima Laboratory 4. Extent and methods of demolition Demolish, or remove and reinstall as applicable, all, or parts of, site work interfering with new construction, masonry, concrete, walls and partitions, floor and roof construction, roofing, parapet construction, doors, frames, metal protection finish hardware, plaster, gypsum board, false ceilings, suspension systems, fixing system, furring, lathing, finishes, cabinetry, ventilation items, plumbing fixtures, mechanical and electrical equipment, piping, lighting, telephone central, metallic structure, and other materials and items as necessary to do the work under this contract and, in addition, where removal is indicated. a. Use methods required to complete work within limitations of governing regulations. b. Proceed systematically. c. Demolish concrete and masonry in small section. d. Also demolish or remove walls and partitions in small sections whatever the materials of construction. e. Remove materials so as to not impose excessive loads to supporting walls, floors, or framing. f. Doors: Completely remove all existing doors, windows, frames, and metal protection. g. Remove all plaster on walls, columns and ceiling where approved and keep the area clean for receiving the new finishings. h. Floors 1. When removing existing walls and partitions resting on the structural slab, also remove traces of mortar and other materials to expose structural slab beneath the location of partition or wall. 2. Completely remove existing finish flooring. Leave top of exposed substrate completely free from materials that would interfere with bond of new materials. 3. Completely remove existing tiles. Leave top of exposed substrate completely free from materials that would interfere with bond of patching, topping, or finish material. 4. When removing existing floor finishes, completely remove loose materials and damaged substrate materials. 5. Completely remove existing asphalt, flower beds and leave top of surface free from materials that would interfere with bond of new materials. 6. Where Contract requires removing existing concrete foundations, concrete slabs, and stairs also remove reinforcement. When filling openings with concrete, prepare slab edges as shown. i. Ceilings 1. Where existing false ceilings have been removed, existing hangers and hanger attachments shall be removed. Site Works-Page 4 Agriculture and Rural Development Program Rehabilitation of Kfarshima Laboratory j. 5. 6. 7. 8. 9. Walls 1. Remove existing wall finishes and prepare surfaces to receive indicated new finishes. Leave nothing that will affect new finish. Where substrates will be exposed in the completed work, remove every trace of old finish. 2. Remove supports for existing finishes removed under this Contract or earlier. k. Remove concrete water tank on roof in small sections. l. Remove all water proofing system on roof and upper roof as agreed by the Contracting authority. m. Demolish all concrete work related to the central stair and lift in all levels, in small section. n. Remove external fence. o. Remove telephone central carefully in a way not to be damaged, to a place approved by the Contracting authority. p. Remove all equipment related to Bathrooms and main kitchen in all levels. q. Remove all built-up furniture in all levels. r. Other Materials and Items: Remove where removal is necessary to permit work under this Contract. Remove such items and materials only to extent necessary. Satisfactorily and promptly repair damage to existing materials and equipment to remain, or provide new equal approved products at no additional cost. Cutting and drilling a. Cut and drill existing construction to permit the work under this Contract. Include cutting holes and other openings for plumbing, mechanical, and electrical work. b. Cut by hand or with small power tools when possible. Cut holes and slots neatly to size required, with minimum disturbance of adjacent work. Cut round holes in concrete using core drills. Cut square and rectangular holes by line drilling and using chipping hammers to remove material between drill holes. Do not use large air hammers. c. Do not operate air compressors inside building unless otherwise approved by the Contracting authority. d. Do not drill or cut structural supporting elements without specific approval in each case, unless the element is shown on structural drawings to be drilled or cut. do not cut existing concrete slab reinforcement. e. Cover openings temporarily when not in use, and patch as soon as work is installed. Patching Promptly repair all damage to work not indicated to be removed at no cost to Owner. Match existing adjacent materials and surfaces to satisfaction of Contracting authority. Grub up services Grub up gulleys, break up manholes etc. Stop off all disused drains at point of entry and seal with concrete. Remove all water supply pipes at point of entry; plug and seal all dead ends. Removal of plant The Contractor shall, upon completion of the demolition works, remove and clear away all temporary plant, rubbish and superfluous materials, and shall leave the Site in a clean and tidy state, debris to the satisfaction of the Contracting authority. Site Works-Page 5 Agriculture and Rural Development Program Rehabilitation of Kfarshima Laboratory EXCAVATION & EARTHWORK A. Scope These works shall consist of all excavation in any material for basement, retaining walls of all types, and for other major or minor structures; and including all necessary clearing and grubbing; bailing; drainage, pumping, sheeting; temporary shoring and cribbing; construction of temporary cofferdams or cribs; and disposal of all excavated material and backfilling with suitable approved material; all as and where shown on the Drawings. 1. These works shall also include the removal of those portions of existing structures below ground which would in any way obstruct or interfere with construction of new structures 2. The Contractor will be deemed to have satisfied himself, at the time of tendering, as to the type and nature of soils and rock that will be encountered in structural excavations. B. 1. 2. Performance and Standards All materials and workmanship shall comply with the latest edition of relevant British Standards and with the Specification. In particular the recommendations of BS 6031 shall be complied with. Relevant Standards Testing of Soils : in accordance with BS 1377. Earthworks : in accordance with BS 6031. C. Related Items Regulatory Requirements Cast-In-Place Concrete D. 1. 2. Submittals The Contractor shall, before commencing any excavation, survey and level the whole of the site, and shall prepare plans and sections accordingly. The plans and sections shall, when finally and mutually agreed, be signed by both the Contracting authority and the Contractor as truly representing the configurations of the site in question before the commencement of excavation Items included are : − Details of plant and equipment − Proposed sequence of works − Proposals for ensuring stability of excavations − Proposals for maintaining excavation free of standing water. − Plans and sections of type and method proposed for piling to be approved by the Contracting authority Temporary support system a. When a temporary support system is required to protect the existing building, adjacent property or to protect the public during construction, the Contractor’s design for such support system shall be submitted for approval prior to commencing its construction. b. All temporary systems shall be designed with adequate factors of safety to serve with Site Works-Page 6 Agriculture and Rural Development Program Rehabilitation of Kfarshima Laboratory c. E. 1. 2. F. 1. G. 1. 2. minimal maintenance, for the duration of its intended use, and shall include adequate safety provisions to protect the public from construction activities. Notwithstanding any approval of temporary support systems, the Contractor shall be solely responsible for the adequacy of their design and construction and for maintenance and all necessary safety precautions associated therewith. Product Handling Disposal of excavated material The Contractor shall remove soil from excavation and shall place it at a dumping point designated (or approved) by the Contracting authority which may be in embankments in temporary heaps or in permanent soil tips, according to the quality of the material, the need of it for filling and other circumstances, as directed by the Contracting authority. Explosives : The use of explosives is forbidden. Materials Definition and classification of earthworks materials − The Contracting authority will determine the classification of excavation and earthworks materials in accordance with the definitions hereinafter. − “Suitable material” shall comprise all material which in the opinion of the Contracting authority is acceptable for use in the Works. − “Unsuitable Material” shall mean other than suitable material and shall not be accepted for use in the works. − “Rock” shall mean any hard natural or artificial material requiring the use of blasting or other special machines or tools for its removal, but excluding individual masses less than 0.1m3 in trenches and 0.2m3 in general excavation. Workmanship Site and Sub-soil Conditions The Contractor shall be fully responsible for ascertaining all site and sub-soil conditions affecting the excavations and earthworks. These shall include but not be limited to information concerning the nature of the ground and periods of rainfall. The Contractor shall satisfy himself that the existing ground levels as indicated on the drawings are correct and shall bring to the attention of the Contracting authority any levels considered to be in error before disturbing the affected ground. Methods 1. The methods adopted for the excavation and earthworks shall be determined by the Contractor. 2. The Contractor shall carry out the work in whatever material may be encountered and shall use such methods and provide and operate such plant and equipment as may be necessary to deal with every class of material. 3. The use of explosives is forbidden. 4. The Contractor shall notify the Contracting authority a sufficient time in advance of the beginning of any excavation so that the Contracting authority may, where necessary, survey and record the cross sectional elevations and measurements of the existing Site Works-Page 7 Agriculture and Rural Development Program Rehabilitation of Kfarshima Laboratory 3. ground and existing structures affected by the proposed structure. Any materials removed or excavated before these measurements have been taken and approved by the Contracting authority will not be paid for. 5. All excavation in whatever material may be met, for reducing level shall be carried out to the lines and levels shown on the drawings or to such lines and levels as ordered by the Contracting authority. 6. Where excavation to rock foundation is required, the excavation shall proceed in such a manner as to allow the solid rock to be exposed and prepared in horizontal beds or properly serrated for receiving the concrete. All loose and disintegrated rock and thin strata shall be removed. 7. When unstable material or other unsuitable material is encountered below foundation elevation, the Contractor shall excavate such material and replace it with suitable backfill material or concrete as directed by the Contracting authority. 8. The foundation shall be excavated in accordance with the dimensions as shown on the drawings and shall be of sufficient size to permit the placing width and lengths of the footings. 9. If temporary works are required for maintaining the excavation dry, the Contractor shall be responsible for the design and execution of the Works. The proposed design shall be submitted to the Contracting authority for approval, however, such approval does not relieve the Contractor of his sole responsibility in this regard. 10. The Contractor must notify the Contracting authority of any sign of failure or cracks within or around the excavation immediately when such signs are noticed. Dimensions 1. The excavation shall be carried to the elevations shown on the Drawings or as established by the Contracting authority. Borings and soil tests made during design and actual investigation of the completed foundation excavations shall be utilised by the Contracting authority to determine final depth. No concrete shall be placed prior to approval of the excavation pit. 2. In the event of excavations being made larger than the sizes shown on the drawings or as instructed by the Consultant, the Contractor shall fill in the excavated void to the correct profile using material as specified hereinafter or as directed by the Contracting authority. 3. Foundation pits or trenches shall be sufficient size and provide minimum sufficient working space to permit construction of structures or structure footings of the full width and length shown on the Drawings. 4. Where footings are to be constructed using formwork, the excavations shall generally not extend more than 500 mm beyond the maximum dimension on each side of the proposed footing unless additional working space is clearly required and approved by the Contracting authority. Any unauthorised over- width of excavation beyond the lateral limits shown on the drawings or approved by the Contracting authority shall be backfilled with selected fill or lean concrete as directed by the Contracting authority. 5. Where footings are to be located, in or adjacent to firm, original ground and where formwork is not required or ordered, any unauthorised over-depth excavation below the approved elevation of base of footing shall be backfilled with blinding concrete. Site Works-Page 8 Agriculture and Rural Development Program Rehabilitation of Kfarshima Laboratory 4. 5. 6. 7. 8. Protection of Personnel etc … 1. The Contractor shall take such precautions as are necessary to ensure the protection of personnel on or adjacent to the site and the maintenance and protection of any adjacent property, structures or roads. 2. In areas where the excavation is adjacent to public roads and walkways, the Contractor shall erect all necessary barricades, barriers, enclosed walkways, and warning signs necessary to restrict the exposure of the public to the excavation. 3. The Contractor shall take all necessary precautions, including shoring or otherwise, to protect employees in the excavation and on the ground above. The Contracting authority will not enter excavated areas to approve the foundation and further Works until he deems the areas to be safe. 4. The Contractor shall take all necessary precautions specially for shoring existing concrete works (footings, columns , walls, tie beams, etc,…) and shall be responsible for the safety of this works, approval of the Contractor’s support system shall not relief the contractor from his responsibility in this regard. 5. The Contractor shall be solely responsible for the safety at all times of all foundation and trench whether supported or otherwise. Approval of the Contractor’s support system or omission of a support system for any excavations shall not relief the Contractor from his sole responsibility in this regard. Stability The Contractor shall ensure the stability of all excavations and Earthworks by the provision of suitable side slopes, shoring or such other means as may be necessary. Should any slips, falls or settlement occur they shall be made good by the Contractor using methods and materials approved by the Contracting authority. Where shoring is used for the sides of excavations, it shall be removed as work proceeds except where instructed otherwise by the Contracting authority. Before commencing any excavation or earthwork the Contractor shall if requested submit his proposals for ensuring its stability and obtain the Contracting authority’s approval. Maintaining excavation and earthworks free from water. The Contractor shall arrange the rapid disposal of water shed onto or entering the excavations or earthworks from any source at any time during the construction. In pumping out excavations the Contractor shall ensure the stability of all structures, excavations and earthworks. Excavation of cuttings The sloping sides of cuttings shall be cleared of all rock fragments which move when prised with a crow-bar. Where in the slopes of cuttings layers of rock and soft material alternate and the Contracting authority considers that the slope, immediately after dressing, will not permanently withstand the effects of weather, the Contractor shall excavate any insecure material to an approved depth and build up the resulting spaces with concrete or masonry using rock similar to the adjoining natural rock so as to ensure solid face. Backfilling and compacting 1. The Contractor shall obtain approval for his proposed method and rate of placing of Site Works-Page 9 Agriculture and Rural Development Program Rehabilitation of Kfarshima Laboratory backfill, before backfilling commences. 2. Backfill materials shall be uniformly graded granular material, capable of being compacted to required compaction, and having adequate permeability to permit free drainage through it. Backfill material shall also conform to the following: − Minimum D10 value 1 mm − Maximum Plasticity Index 10% 3. In case excavated material is not sufficient to backfill or shall prove unsuitable, filling material shall be imported to the site from a source approved by the Contracting authority, at the Contractor’s expenses. 4. Backfill material shall not be placed against any structure until approval is given. Unless otherwise shown on the Drawings Structures shall be backfilled to the same requirements as specified for the same embankment. 5. Backfill shall be placed in level layers for the full width of the excavated area until the elevation of the original ground or surrounding embankment is reached. Backfill next to walls or in other confined areas, shall be compacted by approved hand or portable equipment. 6. Each successive layer of backfill shall contain only sufficient material to ensure proper compaction and in no case shall be greater than 250 mm thickness (before compaction). The moisture content of the backfill shall be uniform and within the moisture range designated. 7. Additional water to be added during placement of backfill material to achieve required compaction shall be fresh water or brackish water approved by the Contracting authority. 8. Minimum tests required during backfilling operations to verify material are: − One Proctor test − One Gradation of materials and at change of material or its source − One Plasticity Index and field density for all compacted layers. 9. Structures shall not be subject to the pressures of backfilling or to live loads until the 28day strength of the concrete has been reached, unless a shorter period is approved in special circumstances where the load is sufficiently small as not to constitute a risk of any damage to the structure in the opinion of the Contracting authority. If approved this period may be extended if subnormal curing conditions exist. 10. Backfill underground slabs, paving, etc. … shall be free from organic and other unsatisfactory material such as rocks exceeding 70mm. The Backfill shall be thoroughly compacted by wetting the material to the optimum moisture content and rolling with a vibratory roller to the satisfaction of the Contracting authority. 11. Westergaard tests on final layer of backfill, are to be carried out and result should be not less than 30 Mpa/m. 12. Backfill around retaining walls shall be completed to the level as shown on the Drawings or as directed by the Contracting authority. Care shall be exercised to prevent forward movement of the wall. Site Works-Page 10 Agriculture and Rural Development Program Rehabilitation of Kfarshima Laboratory ASPHALTIC CONCRETE PAVING A. Scope This section covers asphaltic concrete paving as shown on the drawings and as specified by the Contracting authority. B. Performance and Standards All materials shall be to the satisfaction of the Contracting authority. C. Materials Asphalt work shall be as follows: Fine aggregate sub-base course (max. 4mm) thickness as shown on drawing. Prime coat medium curing not liquid asphalt - (1.0-1.5 kg/m2). Tack coat asphalt emulsion - (0.2-0.6 kg/m2). Asphalt aggregate (60mm thick) minimum as shown on drawings. D. Workmanship Proof roll the fine aggregate and do all necessary rolling and compacting where needed to obtain firm, even subgrade surface. Proof roll subgrade to seek out any soft or pumping soil by making at least four (4) perpendicular passes with a static compactor weighting at least 9.1 metric tons. Fill and consolidated depressed areas. Remove incompatible material, replace with new fill and compact. Verify frames for manholes, drain inlets and other such units within areas to be paved, are at their proper elevation. Adjust frames as required to match paving. Provide temporary closures over openings until completion of rolling operations. Remove closures at completion of the work. Set covers to grade, flush with the surface of adjoining pavement surface. Install fine aggregate where needed or as directed by the Contracting authority in a single lift of the thickness indicated on drawing. Roll from edge of surface gradually proceeding toward center, with a static compactor weighting at least 9.1 metric tons. Compact to maximum dry density until a uniform, firm, sound surface has been established complying with the lines, grades, elevations and cross-sections required. Moisture may be added to aggregate materials to provide workability and aid compaction. Undercut and remove all unsuitable materials and replace fine aggregate areas into which mud has been "pumped" with new aggregate to the full depth and in accordance with applicable Specifications, prior to placing overlying materials. Fine aggregate may be used as wearing surfaces during the construction period. If so used remove and replace damaged portions and clean entire surface to the satisfaction of the Contracting authority prior to placing overlying materials. Apply prime coats to cleaned contact surfaces of Portland Cement concrete item such as curbs, edges of pavement, gutters, manholes, drains and other structures in thin uniform coatings prior to placing asphaltic concrete materials against these items. Allow prime coats to dry and cure as required. Place in one lift and compact to maximum dry density until a uniformly-smooth, hard surface has Site Works-Page 11 Agriculture and Rural Development Program Rehabilitation of Kfarshima Laboratory been established, complying with the lines, grades, elevations, and cross sections required. Place, spread, and strike off the asphalt mixture on a properly prepared and conditioned surface. Inaccessible and small areas may be placed by hand. Place in one lift and compact to maximum dry density until a uniformly smooth, hard surface has been established, complying with the lines, grades, elevations, and cross sections required. Place materials in strips not less than 3m wide where practical. After the first strip has been placed and rolled, place all succeeding strips an extend rolling to overlap previous strips. complete base for a section before placing surface course materials. Carefully make joints between old and new pavements, and between successive day's work, to ensure a continuous bond between adjoining work. construct joints to have the same texture, density and smoothness as other sections of the asphalt course. Begin rolling operations when the asphalt concrete mixture will bear the weight of the roller without excessive displacement. compact areas inaccessible to rollers with vibrating plate compactors. Perform breakdown, second and finish rolling until the asphalt concrete mixture has been compacted to the required surface density and smoothness. Continue rolling until all roller marks are eliminated. Provide a smooth compacted surface true to thickness and elevations required. After final rolling, do not permit vehicular traffic on the pavement until it has cooled and hardened, and in no case sooner than 8 hours. Protect newly placed material from traffic by barricades or other suitable methods. E. Lane Markings Provide indicated painted lines and marking 100mm wide for asphaltic concrete paving and other paving works placed under this contract. Include where indicated: 1. Parking spaces 2. Arrows and car numbers 3. Other markings if indicated. Site Works-Page 12