Analysis of a Toggle Mechanism:

Sensitivity to Link Sizes and Compliance Material

by

Joseph P. Hughes

A Project Submitted to the Graduate

Faculty of Rensselaer Polytechnic Institute

in Partial Fulfillment of the

Requirements for the degree of

MASTER OF ENGINEERING

Major Subject: MECHANICAL ENGINEERING

Approved:

_________________________________________

Professor Ernesto Gutierrez-Miravete, Project Adviser

Rensselaer Polytechnic Institute

Hartford, Connecticut

August 2012

(For Graduation December 2012)

© Copyright 2012

by

Joseph P. Hughes

All Rights Reserved

ii

CONTENTS

LIST OF TABLES ............................................................................................................ iv

LIST OF FIGURES ........................................................................................................... v

LIST OF SYMBOLS ........................................................................................................ vi

ABSTRACT .................................................................................................................... vii

1. Introduction.................................................................................................................. 1

2. Theory/Methodology ................................................................................................... 4

2.1

2.2

Linkage Stress Evaluation .................................Error! Bookmark not defined.

2.1.1

Effect of Link Length on Stress within the Linkage .............................. 8

2.1.2

Effect of Compliant Material Choice on Stress within the Linkage ...... 8

Methodology Used during the Finite Element Analysis (FEA) ......................... 9

2.2.1

Model Used during Analysis .................Error! Bookmark not defined.

2.2.2

Element Choice for the Evaluations ..................................................... 12

3. Results and Discussion .............................................................................................. 14

3.1

Baseline Evaluation of the Toggle Mechanism ................................................ 14

3.2

Toggle Mechanism Sensitivity to Linkage Length ........................................... 16

3.3

Toggle Mechanism Sensitivity to the Compliant Material Choice .................. 18

4. Conclusion ................................................................................................................. 20

References........................................................................................................................ 21

Appendix.......................................................................................................................... 22

iii

LIST OF TABLES

iv

LIST OF FIGURES

Figure 1: Toggle Mechanism [Reference (1)] .................................................................. 1

Figure 2: Finite Element Analysis Components ............................................................. 12

Figure 3: Boundary Conditions for Linkage ................................................................... 12

Figure 4: Linkage Modeled and Meshed in ABAQUS .................................................. 14

Figure 5: Stress of Element 618 during the travel of the linkage (baseline) .................. 15

Figure 6: Location of Element 618 ................................................................................. 15

Figure 7 : Stress in Linkage at the Toggle Location of the Linkage (toggle location was

enlarged to show more detail).................................................................................. 16

Figure 8: Stress levels within Element 618 throughout the travel of the linkage (with

0.005 in shorter links) .............................................................................................. 17

Figure 9: Stress distribution within linkage as it passes through toggle......................... 18

Figure 10: Stress within Element 618 throughout the travel of the linkage (with BeCu

compliant material) .................................................................................................. 19

Figure 11: Stress within linkage as it passes through toggle with BeCu stop ................ 19

v

LIST OF SYMBOLS

𝐿 – Length of the links

𝐻 – Height of the links

𝑡 – Thickness of the links

𝐿𝑒𝑛𝑑𝑝𝑜𝑖𝑛𝑡 – Distance between the end points of the links

𝛿𝑐𝑜𝑚𝑝𝑟𝑒𝑠𝑖𝑜𝑛 – Compression of each link

𝜀𝑙𝑖𝑛𝑘 – Strain within each link

Ε – Modulus of Elasticity

𝐸𝑙𝑖𝑛𝑘 – Modulus of Elasticity of link

𝜎 – Engineering stress

𝜎𝑙𝑖𝑛𝑘 – Engineering stress of link

𝜎𝑦𝑖𝑒𝑙𝑑 – Allowable yield stress of the link

𝜖 – Engineering strain

𝜀𝑙𝑖𝑛𝑘 – Engineering strain of link

𝐹 – Force

𝐹𝑙𝑖𝑛𝑘 – Force within the link

𝐴 – Area

𝐴𝑃𝑖𝑛 – Area pin

𝑑𝑃𝑖𝑛 – Diameter of pin

𝐿𝑛𝑒𝑤 – New length of the link

𝜏𝑝𝑖𝑛 – Shear stress within the pin

𝜏𝑎𝑙𝑙𝑜𝑤𝑎𝑏𝑙𝑒 – Allowable shear stress within the pin

vi

ABSTRACT

Toggle mechanisms are commonly used within linkages in order to lock their position.

These mechanisms do this by passing through a “toggle” point where any force into the

linkage would cause the linkage to maintain its position. While passing through the

“toggle” point, there is a great deal of stress applied to the links. The purpose of this

investigation was to evaluate the impact that a change in length of the links or change in

the choice of material for the compliant element within the linkage has on the stress

within the linkage. It was found that a small decrease in the length of the links resulted

in a large decrease in the stress within the linkage. Additionally, it was found that the

addition of a compliant material to the linkage also resulted in a reduction of stress

within the linkage. However, the compliant material did not reduce the stresses as much

as the reduction in length of the linkage. The sensitivity of the stress within the linkage

to small variations within the length of the links is the reason that many toggle

mechanisms, such as those used in pliers come with an adjustable component that can

account for any variations that may occur during manufacturing.

vii

1. Introduction

Toggle mechanisms are commonly used within linkages and serve many purposes.

These purposes include: transferring rotational motion into linear motion, magnify input

loads (due to the mechanical advantage that a toggle mechanism affords), and locking

the position of a linkage.

In all of these applications, the links within a toggle

mechanism experience a great deal of stress, especially when used to lock the position of

a linkage. As the toggle mechanism passes through the toggle position each of the links

are compressed creating a large amount of stress within the link. Figure 1 provides an

illustration of the toggle mechanism used throughout this evaluation.

Figure 1: Toggle Mechanism

Figure 2 shows the components that comprise the toggle mechanism. This mechanism

consists of two links, a slide, a stop, and three connecting pins. The two links are able to

rotate about their connecting pins and the slide allows translational movement (left to

right as shown in Figure 2) until it contacts the stop which resists any additional

translational movement.

Figure 2: Components within Linkage

1

Figure 3: Linkage movement from given displacement

During this evaluation, the pin is pushed vertically down forcing the other two links to

rotate about their endpoints and the slide to translate towards the right (as pictured in

Figure 3). When the pin is pushed a sufficient distance, such that the adjacent links are

aligned, the mechanism is said to be at its “toggle” point (see Figure 4). At this position

the components within the linkage have experienced their greatest compression and

therefore their greatest amount of load. As the mechanism passes this point, it is said to

travel “over-toggle” (see Figure 5), and the stress within the linkage begins to dissipate.

Often this “over-toggle” position is used, in conjunction with a hard stop for the links, to

lock a linkage in place as any forces from the outside pins would force the force the

middle pin further down and into the potential hard stop. Additionally, because of the

large forces experienced within a toggle mechanism, there is a component that is

compliant and takes some of the stress created by the interference between the links as

they pass into the over-toggle position.

Additionally, the compliant material also

provides a constant force back into the linkage helping lock it into the over-toggle

position.

Figure 4: Toggle mechanism at "toggle" point

2

Figure 5: Toggle mechanism in "over-toggle" position

This evaluation examines the stress within the linkage as it passes through the toggle

position specifically the impact that the linkage lengths (links 1 and 2) and material

choice for the compliant element within the linkage have on the stress levels within the

linkage. This analysis consists of the three steps: 1) establishing a baseline linkage and

evaluate the stress in the linkage as it passes through the toggle point, 2) evaluating the

impact of the length of the links, and 3) evaluating the impact of the spring rate of the

compliant element of the system. The first evaluation will establish a baseline stress

level in order to evaluate the two changes to the linkage (length of links and compliant

material choice). The next two evaluations are performed in isolation to each other. In

other words, the baseline model is used and only the length of the links is altered and

conversely when the compliant material choice is evaluated it too is the only change

from the baseline model. This way the two variables can be evaluated independently

and compared back to the same baseline to compare the severity of the impact each

component has on the stress values within the linkage. The linkage length was chosen as

a variable to evaluate as machining tolerances are used on components during

manufacturing. This evaluation will determine the impact of those machining tolerances

on the stress levels within the linkage.

When designing a toggle mechanism, the

designer may choose to utilize a compliant material to reduce the force within the links

as it passes the toggle point or, in the case of table top clamps, to hold a component for

machining without damaging the component. It is important to know how much of an

impact that this choice of compliant material has on the stress levels within the linkage.

3

2. Theory/Methodology

2.1 Kinematic Relationship within Linkage

A toggle mechanism is a type of linkage, a connection of links able to transmit motion

and forces. As such, its motion is governed by kinematic and linkage theory. The toggle

mechanism used throughout this evaluation is limited to planar motion, meaning all

motion within the linkage (rotational or translational) occur within the same plane. A

link in planar motion has three degrees of freedom (see Figure 6), however, when it is

added to other links within a linkage, some of these degrees of freedom are constrained.

Figure 7 illustrates the allowable degrees of freedom for each of the joints within the

linkage. This linkage consists of three links in total (four including the ground), three

revolute and one prismatic joint. A revolute linkage is one that is allowed only the

angular degree of freedom. A prismatic link is one that is allowed to slide along one

degree of freedom. Using this information it is possible to theoretically determine the

degrees of freedom that the linkage has using the Gruebler and Kutzbach equation [].

This equation evaluates the mobility of the linkage based on the number of links

(including the ground link) and the number of joints allowing one degree of freedom and

the number of joints allowing two degrees of freedom. All of the joints within this

linkage allow only one degree of freedom.

Figure 6: Degrees of freedom of a planar link

4

Figure 7: Degrees of freedom within the linkage

Gruebler and Kutzbach Equation:

m = mobility of the linkage

n = number of links within the linkage

J1 = one degree of freedom joints

J2 – two degree of freedom joints

m 3(n 1) 2 J 1 J 2

m 3(4 1) 2(4) 0

m 1

Therefore, this linkage has only one degree of freedom. Upon review of the linkage, this

result makes sense as the linkage is driven off of the motion of one of the links. It is

important to understand the travel of the linkage and kinematic relationship between

each link within the linkage to understand how the linkage moves and there by be able to

calculate how the forces will be transmitted through the linkage.

The kinematic

relationship between the position of the slide and the angular position of link 1 is shown

in Figure 8 and calculated by the following equation; where “L” is the length of each

link

and

“α”

is

the

Llink1 Llink2 cos( ) Lslide .

angular

position

of

the

link

(see

Figure

8):

This equation allows the designer to evaluate a correct

placement of the stop in the linkage. When the linkage is at its toggle point α = 0 and

therefore the distance to the end of the slide is the sum of the lengths of each component.

Any difference in this sum of the component lengths and the distance between the

leftmost pin and the left face of the stop would be accounted for in deflection of the

links. Knowing this information, one is able to calculate the force within the linkage and

stress within the linkage using basic principles of strength of materials. Therefore,

knowing the allowable stress within the components in the linkage, the stop can be

5

placed such that the forces within the linkage from contact with the stop will not exceed

the limits of the material. Figure 8 provides a representation of the linkage that will be

used throughout this section to discuss the methodology behind the calculation. Link 1

is represented by the black line, link 2 by the red line, the slide by the green line, and the

stop by the black block.

Figure 8: Linkage representation

2.2 Evaluation of the Linkage

The theory behind the analysis of the toggle mechanism is based off of basic principles

of strength of materials. As stated before, this evaluation is broken into three steps: 1)

establishing a baseline linkage and evaluate the stress in the linkage as it passes through

the toggle point, 2) evaluating the impact of the length of the links, and 3) evaluating the

impact of the spring rate of the compliant element of the system. The theory behind

each of the steps of the analysis is the same. However, the impact that each of the

changes (link length and compliant element material choice) will be discussed as it

relates to the theory behind the analysis in sections 2.2.1 and 2.2.2.

The linkage

representation provided in Figure 8 will be used throughout this discussion. For this

discussion each of the links will be modeled as a beam element with the general stiffness

of k =

AE

and all deflection in the linkage is due to compressive loading (any bending

L

will be ignored). Ignoring bending for this discussion is a valid assumption as the links

are not expected to experience significant bending during the linkage movement. The

mechanism is close to its toggle point (with the link all aligned) when the majority of the

loading occurs and therefore the driving stress will be compression.

6

Additionally,

during this discussion the pins are not individually accounted for, assuming instead that

they act within the stiffness of each of the links. The forces between the links will then

be used to evaluate the stress within the pins.

Each of the links (and stop) within this mechanism can be treated as a spring where:

𝐹𝑖 = −𝑘𝑖 𝜕𝑖

𝑘𝑖 =

𝐴𝑖 𝐸𝑖

𝐿𝑖

𝐴𝑖 = 𝑤𝑖 × ℎ𝑖

Where i is 1 for link 1, 2 for link 2, 3 for the slide, and 4 for the stop and 𝑤𝑖 is the width

of each link and ℎ𝑖 is the height of each link. The total length of the linkages (Ltotal) less

the length between the left pin of link 1 and the right side of the stop (Lavailable) is the

total deflection within the linkage (δlinkage).

4

𝐿𝑡𝑜𝑡𝑎𝑙 = ∑ 𝐿𝑖

𝑖=1

4

𝜕𝑙𝑖𝑛𝑘𝑎𝑔𝑒 = 𝐿𝑎𝑣𝑎𝑖𝑙𝑎𝑏𝑙𝑒 − 𝐿𝑡𝑜𝑡𝑎𝑙 = ∑ 𝜕𝑖

𝑖=1

As shown in the force diagram, provided in FIGRUE, all forces within the linkage are

equal. This means that the 𝑘𝜕 for each link will also be equal. As each link is made

from the same material and therefore has the same E, the E can be dropped from each

equation resulting in:

𝐴1

𝐴2

𝐴3

𝐴4

𝜕1 =

𝜕2 =

𝜕3 =

𝜕

𝐿1

𝐿2

𝐿3

𝐿4 4

Solving each equation for 𝜕𝑖 in terms of 𝜕1 results in:

4

𝐿𝑎𝑣𝑎𝑖𝑙𝑎𝑏𝑙𝑒 − 𝐿𝑡𝑜𝑡𝑎𝑙

𝐴1

𝐿𝑖

= − (𝜕1 + 𝜕1 × ∑ )

𝐿1

𝐴𝑖

𝑖=1

Once 𝜕1 is calculated, one can readily find 𝐹1 which, as previously discussed, is equal to

𝐹𝑖 . The deflection of each of the links is then easily calculated with the force in each

link and the equations provided herein. The stress within each of the links is then

7

calculated using the following equation and compared to the yield strength of the

material (𝜎𝑦𝑖𝑒𝑙𝑑 ).

σ=

𝐹𝑖

𝐴𝑖

The force from the links is transferred into pure double shear loading on the pins (as

assumed due to tight connection of links), therefore:

𝜋 × 𝑑𝑃𝑖𝑛

4

𝐹𝑖

=

2 × 𝐴𝑃𝑖𝑛

𝐴𝑃𝑖𝑛 =

𝜏𝑝𝑖𝑛

Additionally, in accordance with the maximum distortion energy theorem, the allowable

stress for the pin in a pure shear loading case is not the full yield strength of the material

but:

𝜏𝑎𝑙𝑙𝑜𝑤𝑎𝑏𝑙𝑒 = 0.577 × 𝜎𝑦𝑖𝑒𝑙𝑑

2.2.1

Effect of Link Length on Stress within the Linkage

The increase in the length of link 1 and link 2 within the linkage will decrease the

stiffness of each of these links, which for the same deflection, would lower the force in

the link.

However, the increase in length of the link would increase the overall

deflection required in the linkage. The increase in deflection will have a larger impact

on the stresses within the linkage than the reduction in stiffness and therefore it is

expected that the forces and stresses within the linkage will increase with the increase in

linkage length.

INSERT LINKAGE PICTURE SHOWING ADDITIONAL DEFLECTION

2.2.2

Effect of Compliant Material Choice on Stress within the Linkage

The addition of a compliant material will change the Elastic Modulus of the stop (link 4

in the evaluation). Therefore, 𝐸𝑖 cannot be readily canceled during the calculation. As a

result the equations will now look like:

𝐸1 𝐴1

𝐸2 𝐴2

𝐸3 𝐴3

𝐸4 𝐴4

𝜕1 =

𝜕2 =

𝜕3 =

𝜕

𝐿1

𝐿2

𝐿3

𝐿4 4

Solving each equation for 𝜕𝑖 in terms of 𝜕1 results in:

8

4

𝐿𝑎𝑣𝑎𝑖𝑙𝑎𝑏𝑙𝑒 − 𝐿𝑡𝑜𝑡𝑎𝑙

𝐸1 𝐴1

𝐸𝑖 𝐿𝑖

= − (𝜕1 +

𝜕1 × ∑

)

𝐿1

𝐴𝑖

𝑖=1

This adds an amount of difficulty to the analysis, especially if a rubber like material is

utilized. Rubber material tends to be non-linear in nature, depending on the shape of the

component, more specifically its shape factor, and the amount of compression of the

material. Therefore, non-linear material does not lend itself to a single E value (or

stiffness, k value). The shape factor compares the bulge area (or free area) of rubber

components to the loaded area. Simply speaking the more bulge area that is allotted for

a given load area, the “softer” or more compliant the material will be. The reduction in

stiffness of this member means that it will be taking more deflection than the links will.

This will overall reduce the amount of load carried through the links.

INSERT PICTURE THAT SHOWS MORE DEFLECTION ON STOP

2.3 Methodology Used during the Finite Element Analysis (FEA)

The following provides a discussion of the methodology used throughout the analysis of

the toggle mechanism. First a brief discussion on the geometry of the components

within the linkage is provided, along with a discussion on the methodologies used to

apply boundary conditions and ensure proper behavior between links during travel.

Then a discussion is provided on how the analysis was performed, what element type

was used, and what variables within the analysis were investigated.

2.3.1

Geometry of Components

A single linkage model is used for both sensitivity analyses (linkage length and

compliant material choice). The model was built within the ABAQUS program using

their sketching functions as the geometry of the linkage was simple. As shown in Figure

2, the linkage is made of up two links, a slide, a stop, and connecting pins. FIGURES

provide a detailed sketch of each of the links within the toggle mechanism. It should be

noted that the pins were not explicitly modeled for the analysis. Instead a built in hinge

connector function within ABAQUS was used for the pins. This is discussed further in

Section 2.3.3.

9

2.3.2

Meshing Techniques

2.3.3

Assembly of Mechanism

2.3.4

Loading

The pins were not explicitly modeled for the analysis, however, a built in connector

function of ABAQUS, called a hinge connection, was used to simulate this component.

This function allows the links to rotate as they would with a pin without having to model

the contact between the pin and the links. This step saves computational time and helps

the model to more easily converge. This hinge connection can also be setup to provide

the force on the hinge such that secondary analysis can be performed on the pin to

ensure its adequacy.

As shown in FIGURE, link 1 was modeled so that it was able to rotate about its end

without allowing any translational movement. The slide was modeled to allow only

translational movement (right to left as depicted in FIGURE) while restricting any

vertical, translational into the page, or rotational motion.

The back of the stop is

completely fixed, not allowing any translational or rotational movement.

Figure 10 provides the boundary conditions used throughout the analysis. Pins connect

the two links and the slide. Link 1 is only allowed to rotate about the pin on the left.

The slide is allowed to translate right and left (as shown in Figure 10) but not allowed to

move up and down or to twist in any direction. The stop is completely fixed and is set a

certain distance from the slide in order to impart the force in the linkage as it passes

through the “over-toggle” position. The purpose of this analysis was to investigate the

stress within the links of the linkage due to the changes to the linkage (length of the links

and compliant material choice). In order to save computational time, the pin was not

modeled for the left side of link 1 (as shown in Figure 10) but an end constraint was used

to simulate the pin.

10

2.3.4.1 Linkage Length Sensitivity Study

The geometry was created, meshed, and analyzed within the ABAQUS Standard

(implicit) solver as a static problem.

For the sensitivity study on the stress within each link due to the increased length of the

links, all components, including the stop, were assumed to be made from the same

material. During the analysis, the lengths of links 1 and 2, shown in Figure 9, were

altered to evaluate the impact.

The length changes used within the study were

machining tolerances typically used during the design of machinery components (+/0.005”). This change in length can be expected on a machined component. The analysis

would determine the nominal stress in the linkage due to the expected interference

between the links as they pass into the “over-toggle” position. This baseline of the

nominal condition is then compared to the stress values within the links when each is

lengthened (or shortened) by 0.005”.

2.3.4.2 Compliant Material Sensitivity Study

For the sensitivity study to determine the impact of a compliant material within the

linkage on the stress within the links, each analysis was completed with links of the

same length. The FEA was run with different materials used for the stop component.

The baseline for this study is the same as the baseline used in section 2.2.1.1. The stop

for the baseline was made from a steel material.

From there, Beryllium Copper,

urethane, and natural rubber were all evaluated as potential materials used for stops

within the toggle mechanism. Material models were developed for urethane and natural

rubber so that they could be modeled within the FEA with a degree of accuracy. These

non-metallic materials do not behave linearly and are dependent on factors like the bulge

area of the stop (shape factor) and the amount of compression of the material.

Therefore, the behavior of each of these materials (urethane and natural rubber) were

estimated by a model created from data points of known performance of each material

based upon the shape of the stop and the amount of compression expected.

11

Link

Link

Slide

Stop

Figure 9: Finite Element Analysis Components

Link

Link

Slide

Stop

Figure 10: Boundary Conditions for Linkage

2.3.5

Element Choice for the Evaluations

During the evaluations, the model used for the evaluation of the linkage was comprised

of linear brick elements with incompatible modes. These elements, according to the

12

ABAQUS1 instruction manuals, are good general-purpose elements, which for linear

elements, are particularly adept at evaluating bending. Additionally, because they are

linear elements they are lower cost elements computationally, compared with the higher

order elements.

1

ABAQUS Instructional Manual Section 3.2

13

3. Results and Discussion

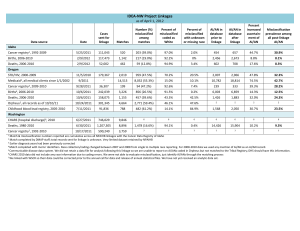

The following section of this report discusses the results of the analysis and provides a

discussion of the impact of linkage length and complaint material on a toggle

mechanism.

Figure 11: Linkage Modeled and Meshed in ABAQUS

3.1 Baseline Evaluation of the Toggle Mechanism

The baseline evaluation model used the same material (steel) for each component of the

linkage. The two links (link 1 and link 2) were of their nominal lengths (2.255 in.).

Figure 12 provides the von Mises stress calculated at element 618 (shown in Figure 13)

throughout the travel of the linkage. At the toggle point of the travel in the linkage

(shown in Figure 14) the maximum stress within the links (located at the pin) is 100 ksi.

This value is in excess of the yield strength of the steel material used within the linkage

which has a typical yield strength of approximately 50 ksi. This was used for the

remainder of this analysis and will be re-evaluated prior to final submittal of the report.

14

Figure 12: Stress of Element 618 during the travel of the linkage (baseline)

Element 618

Slide

Link 1 to Link 2

Connector Pin

Figure 13: Location of Element 618

15

Stop

Figure 14 : Stress in Linkage at the Toggle Location of the Linkage (toggle location was enlarged to

show more detail)

These results from the baseline evaluation will provide the basis for the evaluation of the

impact of the increase in linkage length and choice of compliant material on the stress

levels within the linkage. As discussed above, the stress values obtained from the initial

evaluations far exceed the yield strengths of the material used for the evaluation. The

analysis for this portion of the evaluation is currently being re-run. However, the results

from the following evaluations should still be able to indicate the trends in change of

stress within the linkage, though their exact stress levels will not be the same as the final

submittal.

3.2 Toggle Mechanism Sensitivity to Linkage Length

To evaluate the impact that the change in length of the two links within the linkage has

on the stress levels within the linkage, the length of each link was decreased by 0.005 in

(each link was then 2.25 in in length) and the evaluation was repeated. The value of

0.005 in was utilized, as it is a common machining tolerance that is used for links of this

size. The peak stress levels noted within the linkage were shown to be 23 ksi. This is a

reduction of approximately 80% in peak stress from a reduction of 0.005 in (0.010 in in

total) from the links. The small reduction in length of the links significantly reduces the

amount that each of the links is required to compress to pass through the toggle position

of the linkage. Additional studies are planned to try smaller increments in reduction of

16

length of the links within the linkage to determine the effect of a smaller variation. A

table of results from the several analyses run will then be provided herein to summarize

the impact of linkage length to stress levels within the linkage.

Figure 15: Stress levels within Element 618 throughout the travel of the linkage (with 0.005 in

shorter links)

17

Figure 16: Stress distribution within linkage as it passes through toggle

3.3 Toggle Mechanism Sensitivity to the Compliant Material Choice

To evaluate the impact that the compliant material choice has on the stress levels within

the linkage, the material of the stop was varied and the evaluation was repeated. The

initial material choice for the stop within the linkage was steel for the baseline condition

as documented herein. The first variation from that material choice was the use of

Beryllium Copper (BeCu). BeCu was chosen because it is often used as a spring

material due to its high tensile strength and good ductility. When this material is added

into the system with the same original link lengths (2.255 in), the peak stress levels

noted within the linkage were shown to be 93 ksi. This is a reduction of approximately

7% in peak stress. This is a small reduction compared to the drop in stress resulting

from the reduction in length of the links within the linkage. This material was one of the

stiffer materials to be tested. Neoprene and natural rubber material models are still being

developed and are likely to have a greater impact on the stresses within the system.

18

Figure 17: Stress within Element 618 throughout the travel of the linkage (with BeCu compliant

material)

Figure 18: Stress within linkage as it passes through toggle with BeCu stop

19

4. Conclusion

General conclusions can be made from the data that has been gathered from the

evaluation thus far, with the understanding that the magnitude of the impact each of the

changes has may be different when the evaluation has been completed.

Both the

reduction of length of the links and the change in material properties for the stop reduces

the stresses within the linkage. Each of these changes reduces the amount that the links

within the linkage are required to compress in order to pass the toggle position. The

change in linkage length had a larger impact on the reduction of the stress levels as it

was able to have reduce the compression of the links. The change in compliant material

reduces the stress within the linkage as it requires less force to pass through the toggle

position as it is able to compress the stop more as the compliant material is less stiff.

However, this additional compression of the stop is less than the reduction in the length

of the links.

20

References

(1) DE-STA-CO, Manual Clamps; Monday July 2, 2012,

http://www.mjvail.com/destaco/intropage3.html

(2) Avallone, Eugene; Baumelster, Theodore; Sadegh, Al; Mark’s Standard Handbook

for Mechanical Engineers; McGraw Hill; dated November 2006

(3) Oberg; McCauley, Christopher; Ryffel, Henry; Holbrook Horton; Jones, Franklin;

Machinery’s Handbook 28th Edition, Industrial Press, Inc.; dated February 2008

(4) Tso, Rei-Lum; The Kinematic Synthesis of Toggle Clamps, American Society of

Mechanical Engineers; Volume 120, August 1998; Pages 648-655

21

Appendix

Appendices will be added after the finite element analysis is completed.

22

i