The Value of the

advertisement

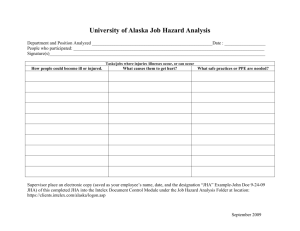

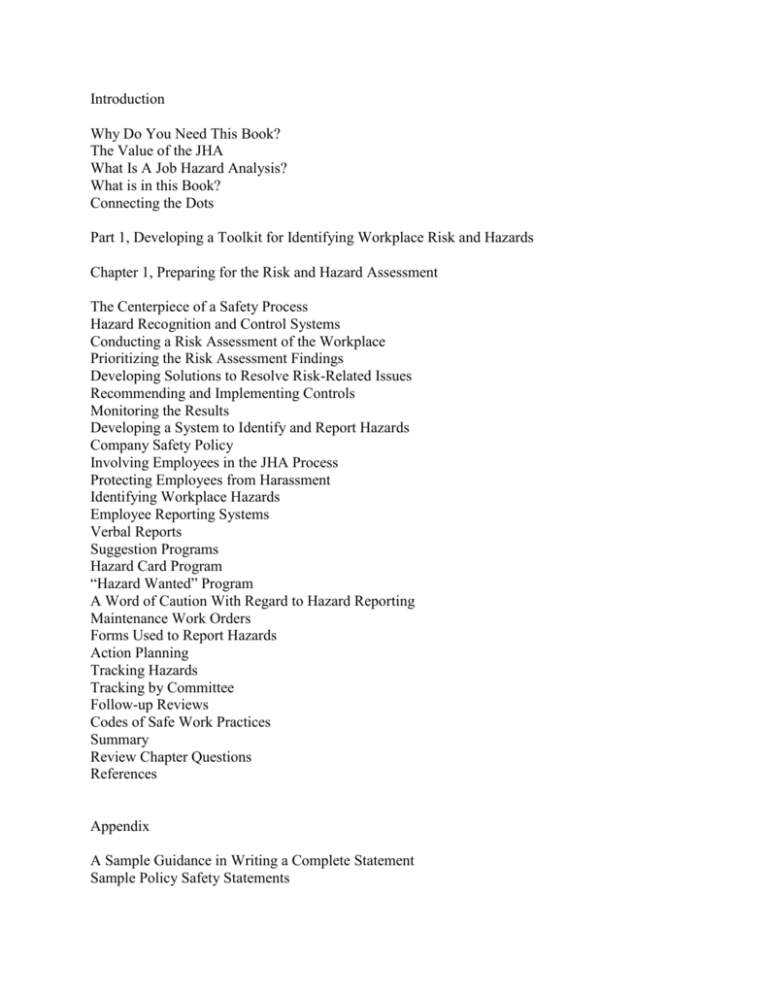

Introduction Why Do You Need This Book? The Value of the JHA What Is A Job Hazard Analysis? What is in this Book? Connecting the Dots Part 1, Developing a Toolkit for Identifying Workplace Risk and Hazards Chapter 1, Preparing for the Risk and Hazard Assessment The Centerpiece of a Safety Process Hazard Recognition and Control Systems Conducting a Risk Assessment of the Workplace Prioritizing the Risk Assessment Findings Developing Solutions to Resolve Risk-Related Issues Recommending and Implementing Controls Monitoring the Results Developing a System to Identify and Report Hazards Company Safety Policy Involving Employees in the JHA Process Protecting Employees from Harassment Identifying Workplace Hazards Employee Reporting Systems Verbal Reports Suggestion Programs Hazard Card Program “Hazard Wanted” Program A Word of Caution With Regard to Hazard Reporting Maintenance Work Orders Forms Used to Report Hazards Action Planning Tracking Hazards Tracking by Committee Follow-up Reviews Codes of Safe Work Practices Summary Review Chapter Questions References Appendix A Sample Guidance in Writing a Complete Statement Sample Policy Safety Statements B Sample Forms for Employee Reporting Of Hazards Tracking Hazard Corrections Follow-Up Documentation C Action Planning Three Sample Versions are Included D Codes of Safe Practices Chapter 2, Workplace Hazard Analysis and Review of Associated Risk Objective Analysis of the Workplace System Inspections and Audits The Checklist Consultant and Outside Specialist Employee Interviews Types of Inspections General Walk-Around Inspections Verification Reviews Focus Reviews Self-Assessment Document Review General Walk-Around Inspections Verification Reviews Focus Reviews Self-Assessment Document Review Written Inspection Reports Who Should Review the Workplace? Supervisors Employees Safety Professionals Preventive Maintenance Programs Other Things to Consider during a Site Inspection Incident Investigations Trend Analysis Summary Review Chapter Questions References Appendix E Self-Inspection Checklists Chapter 3, Developing Systems to Manage Hazards Hierarchy of Controls Why Engineering Controls? Administrative Control PPE PPE Limitations PPE Hazard Assessment Work Practices and Safety Rules General Safety Rules Limitations of Work Practices and Safety Rules Change Analysis A Change in the Process Building or Leasing a New Facility New Equipment Installation Using New Materials Employee Changes Adapting to Change Other Analytical Tools for Consideration: Summary Review Chapter Questions References Appendix F Sample Safety Rules G PPE Assessment Guidelines for complying with PPE requirements Hazard Assessment for PPE, Option 1 Job Hazard Analysis Assessment for PPE, Option 2 Example Personal Protective Equipment Training Certification Form Example Personal Protective Equipment Training Quiz, (RECOMMENDED) Sample PPE Policies, INSTRUCTIONS H Safety Review of New/Relocated Equipment Major Modification Sign-Off Form I Other Analytical Tools for Consideration Part 2, Developing Systems that Support Hazard Recognition Chapter 4, Understanding the Human Role in the Safety Process How are At-Risk Events Developed? What Contributes to an At-Risk Event? The Feedback Loop Behavior Approach Changing Behavior Understanding Why Employees Put Themselves at Risk Understanding the Other Side of Safety Benefits of Behavior-Based Safety Behavior-Based Safety and Integrated Safety Management Functions Seven Guiding Principles of Integrated Safety Management Five Core Functions of Integrated Safety Management Will a BBS Process Work for you? Summary Chapter Review Questions References Appendix J Sample Behavior (At-Risk Events) List Chapter 5, Effective Use of Employee Participation Why Should Employees Be Involved? Involving Employees in the Safety Management System Close Contact with Hazards Improved Support More Participation More Awareness Hawthorne Studies Committee Participation Getting Employee Participation Started Form a Committee How to involve Employees in the Process Joint Labor-Management Committees Other Joint Committees Employee Safety Committees Central Safety Committee Function-Specific Committees Areas of Employee Participation Conducting Site Inspections Routine Hazard Analysis Developing or Revising Site-Specific Safety Rules Training Other Employees Employee Orientation Different Approaches: Union and Non-Union Sites Unionized Work Sites Non-Union Work Sites Forms of Employee Participation What Can Management Must Do Summary Chapter Review Questions References Appendix K Example of a Committee Team Charter Chapter 6, Defining Associated Risk Risk Management General Risk Management Theories and Models People (Employees) The Environment Tools/Equipment/Materials Policies, Procedures, and Management Considerations Job Steps and Task Considerations The System Engineering Model Risk versus Benefit Risk Management Communication Risk Management Responsibilities Supervision Responsibilities Employees Responsibilities Risk Assessment Classification and Ranking Hazards Risk versus Opportunity Safety Significance What Does Success Look Like? Summary Chapter Review Questions References Chapter 7, Assessing Safety and Health Training Needs How is a Good Trainer Defined? Basic Training Principles Types of Safety Education General Safety Instruction How to Conduct Safety Training Training Plan Linked To Consequences Natural consequences System consequences Steps in the Course Development Process Conducting a Training Needs Analysis Developing Learning Activities Establishing Learning Objectives Guidelines for Writing Learning Objectives Components of Learning Objectives Target Audience Audience Analysis Behavior Types of Behavior in Learning Objectives Cognitive behaviors Knowledge-level cognitive behaviors Comprehension-level cognitive behaviors Application-level cognitive behaviors Problem-solving cognitive behaviors Psychomotor Behaviors Affective Behaviors Learning Styles Conditions Course Content Development Delivering Effective Safety Training Safety Program Evaluation Level 1: Measuring Employees Reaction Level 2: Measures KSA's in the Learning Environment Level 3: Evaluates the application of KSA's in the Work Environment Level 4: Evaluates how training has impacted productivity Level 5: Evaluates how training has impacted profits Recordkeeping Other Effective Training “Blues Clues” Training Techniques Improved Self-Esteem? Summary Review Chapter Questions References Appendix L Sample, Safety and Health Training Policy, ANSI Guidelines for Evaluating Training Programs Sample Safety Training Program Audit Sample Training Certification Part 3- Developing an Effective Job Hazard Analysis Chapter 8, Planning for the Job Hazard Analysis Where do I begin? Regaining the “Feel” of the Workplace Conducting the JHA Why is a JHA Important? Benefits of Developing JHA's Drawbacks of a JHA Why Is It Important to Get Employees Involved in the Process? Selecting a Team How do I know that A JHA will Work For Me? Defining the JHA Selecting the Jobs for Analysis Non-Routine Tasks Summary Review Chapter Questions References Appendix M Description of Common Hazards Chapter 9, Breaking the Job Down Into Individual Components Basic Steps in the JHA Development Process Tasks Defined Using a Checklist Methods for Breaking down the Job into Steps and Tasks Discussion Method Observation Method What Tools can be used to enhance the JHA Process? Cameras and Video Equipment Drawings and Sketches “Can’t See the Forest for the Trees” Summary Review Chapter Questions References Appendix N Sample Facility Checklist Chapter 10, Putting together the Puzzle Pieces Completing the JHA Form The Header Job Description Department Date Developed Page Numbering Performed by Approvals PPE Body of JHA Job Steps and Task-Specific Description Risk Assessment Existing and Potential Hazards and Consequences of Exposure At-Risk Events and Preventative Measures Preventative Measures Eliminate the hazard. Substitute Engineering Contain the hazard Administrative Controls Revise work procedures Personal Protective Equipment (PPE) Reduce the exposure Residual Risk Benefit review, Getting the Biggest Bang for the Buck Okay, I have completed the JHA, Now What! Review JHAs until Employee Understands Hazards of Job Revising the JHA Summary Review Chapter Questions References Appendix O Sample instructions on how to change a tire on a car. Sample Job Hazard Analysis Pre-Hazard Assessment Worksheet JHA on Changing a Tire JHA on Changing a Tire, Annotated Comparison JHA on Changing a Tire, Traditional vs. New Version Job Hazard Analysis, Canadian Centre for Occupational Health & Safety (CCOHS) Chapter 11, Standard or Safe Operating Procedures (SOP) How Far is far enough? Why develop an SOP? Elements of an SOP Summary Review Chapter Questions Appendix P Standard Operating Procedure for Changing a Tire Send New Updated File Part 4, Additional Tools That Can Be Used To Develop A Successful JHA Chapter 12, Overview of a Safety Management Process Process Elements What are the Voluntary Protection Programs? How does VPP work? How does VPP help employers and employees? Management Commitment and Leadership Employee participation Hazard Identification and Assessment Hazard Prevention and Control) Education and Training Employee Training Management Training Evaluation of Process Effectiveness The Nature of All Safety Systems Indicators and Measures Assessment Techniques Multi-Employer Workplace Employee Rights Healing a Sick System The PDSA Cycle Voluntary Protection Program Summary Review Chapter Questions References Appendix None Chapter 13, Six Sigma as a Management System: A Tool for Effectively Managing a JHA Process Six Sigma Exposed The Beginning What Does Process Improvement Mean? What Does Process Improvement Look Like? Benefits of Improving a Process Improving the Process Using the Six Sigma Methodology A Basic Six Sigma Process Improvement Model DMAIC Methodology Defining the Project Measuring the Project Analyzing the Project Improving the Project Controlling the Project Define Phase Step 1, Define the Scope of the Project. Selecting the Process Step 2, Developing a Problem Statement Step 3, Define the Appropriate Metric Step 4, Develop Objective Statement Step 5, Select and Organize the “Right” Team. Measure Phase Step 6, Develop a Macro Map of Current Process Step 7, Define the project with Pareto charts, XY matrix, etc. Analyze Phase Step 9, Tool Use (Process Flow, XY Matrix, Gauge Studies, Fishbone, FMEA) Step 10, Identify Root Cause(s) for lack of Capability Using Specific Analysis Techniques Improve Phase Step 11, Design and Conduct Experiment, as applicable Step 12, Defining the Y= f(x) of the Process Control Phase Step 13, Optimizing and Redefining Solutions Step 14, Control Critical X’s and Monitor Y’s Step 15, Verify the Change and Collect Data Key areas of Six Sigma Six Sigma levels Investing in Prevention Pay off!! Positive Changes to Corporate Culture Summary Review Chapter Questions References Appendix Q Cause and Effect Matrix Process Flow Diagram of Changing a Tire based on XY Matrix (Simplified) List the Inputs (Y’s) to the Process XY Matrix for Assessing Job Steps and Task List the Inputs (Y’s) to the Process XY Matrix and Assign Ranking List the process Job steps and inputs (Job Task) XY Matrix for Assessing Job Steps and Task Rank the inputs according to their effect on each output XY Matrix XY Matrix for Assessing Job Steps and Task, Identify the critical inputs from the totals column Final Words, Can You Develop a Culture that Will Sustain Itself? Taking a Closer Look at Reality Reference Appendix R OSHA Regional Offices Glossary Solutions to Chapter Questions