pola27180-sup-0001-suppinfo01

advertisement

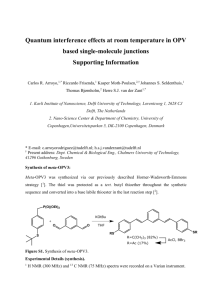

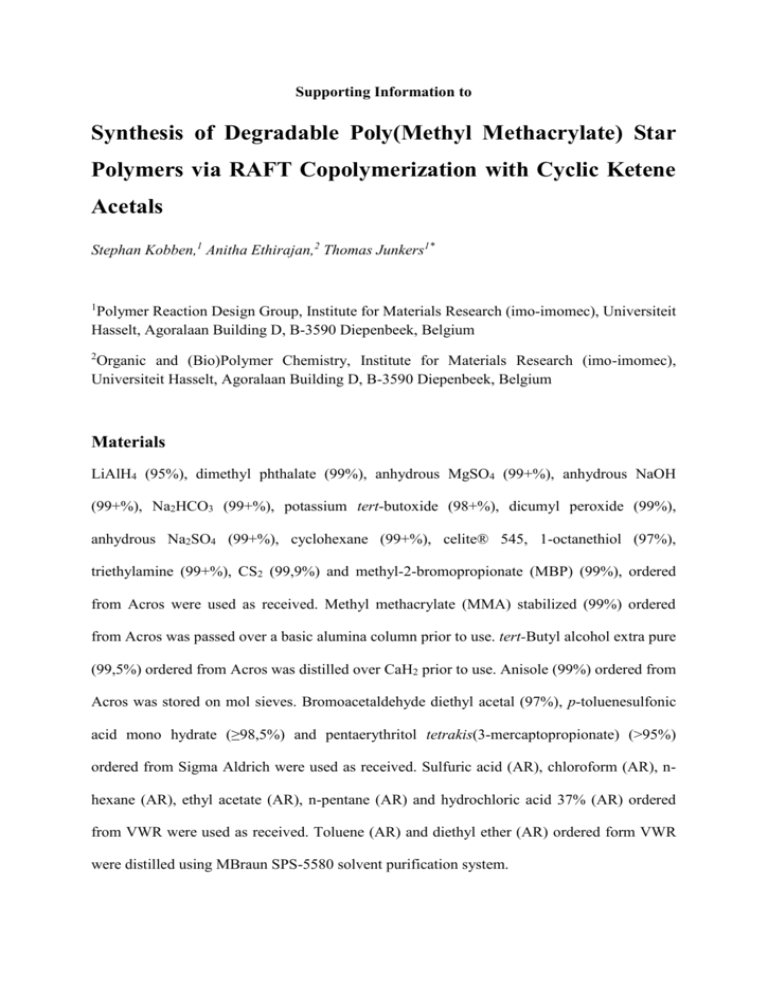

Supporting Information to Synthesis of Degradable Poly(Methyl Methacrylate) Star Polymers via RAFT Copolymerization with Cyclic Ketene Acetals Stephan Kobben,1 Anitha Ethirajan,2 Thomas Junkers1* 1 Polymer Reaction Design Group, Institute for Materials Research (imo-imomec), Universiteit Hasselt, Agoralaan Building D, B-3590 Diepenbeek, Belgium 2 Organic and (Bio)Polymer Chemistry, Institute for Materials Research (imo-imomec), Universiteit Hasselt, Agoralaan Building D, B-3590 Diepenbeek, Belgium Materials LiAlH4 (95%), dimethyl phthalate (99%), anhydrous MgSO4 (99+%), anhydrous NaOH (99+%), Na2HCO3 (99+%), potassium tert-butoxide (98+%), dicumyl peroxide (99%), anhydrous Na2SO4 (99+%), cyclohexane (99+%), celite® 545, 1-octanethiol (97%), triethylamine (99+%), CS2 (99,9%) and methyl-2-bromopropionate (MBP) (99%), ordered from Acros were used as received. Methyl methacrylate (MMA) stabilized (99%) ordered from Acros was passed over a basic alumina column prior to use. tert-Butyl alcohol extra pure (99,5%) ordered from Acros was distilled over CaH2 prior to use. Anisole (99%) ordered from Acros was stored on mol sieves. Bromoacetaldehyde diethyl acetal (97%), p-toluenesulfonic acid mono hydrate (≥98,5%) and pentaerythritol tetrakis(3-mercaptopropionate) (>95%) ordered from Sigma Aldrich were used as received. Sulfuric acid (AR), chloroform (AR), nhexane (AR), ethyl acetate (AR), n-pentane (AR) and hydrochloric acid 37% (AR) ordered from VWR were used as received. Toluene (AR) and diethyl ether (AR) ordered form VWR were distilled using MBraun SPS-5580 solvent purification system. Synthesis protocols Synthesis of 1,2-benzene dimethanol In a one liter three neck flask equipped with a reflux condenser and dripping funnel, 28 grams (0.74 mol) of LiAlH4 was weighed. The set-up was put under inert atmosphere. 500 ml of dry THF was slowly added to the three neck flask. A mixture of 100 ml (0.61 mol) of dimethyl phthalate in 150 ml of dry THF was added to the dripping funnel and was added dropwise to the three neck flask. The reaction was cooled by ice during the addition. After the completion of the addition the temperature was raised to 80°C to maintain a gentle reflux. The reaction was left to run overnight. The mixture was hydrolyzed by gently pouring it into a mixture of 200 ml concentrated sulfuric acid in 750 ml of water. The product was extracted three times with 500 ml of chloroform and the organic phase was washed with 250 ml saturated Na2HCO3 solution and 250 ml of water. The organic phase was then dried over MgSO4. After filtering off the solid, the solvents were removed under vacuum, resulting in a white residue. The product was recrystallized in 500 ml of a 50:50 mixture of chloroform and n-hexane resulting in 72 grams (85%) of white crystals. 1H-NMR (300 MHz; CDCl3): chemical shift (ppm) 2.93 (s, 2H, -CH2-OH), 4.71 (s, 4H, -CH2-OH) and 7.31 (s, 4H, Ar). Synthesis of 5,6-benzo-2-(bromomethyl)-1,3-dioxepane To a 250 ml round bottom flask, 72.02 gram (0.52 mol) of 1,2-benzene dimethanol, 78.4 ml (0.52 mol) of bromoacetaldehyde diethyl acetal and 720 mg of p-toluenesulfonic acid mono hydrate were added. The flask was equipped with a Claisen condenser and the set-up was put under inert atmosphere. The reaction was heated to 120°C and was left to run until most of the expected amount of ethanol (60.7 ml (1.04 mol)) was collected. Afterwards, de reaction was left to cool down to room temperature during which the mixture solidified. The solid was dissolved in 250 ml of chloroform and was washed with 250 ml of saturated Na2HCO3 solution and subsequently with 250 ml of water. The organic phase was dried over Na2SO4. The solvent was removed under reduced pressure leaving a slightly brown solid in the flask. The solid was recrystallized in 500 ml cyclohexane, resulting in 94.62 (75%) of white fluffy crystals. 1H-NMR (300 MHz; CDCl3): chemical shift (ppm) 3.43 (d, 2H, (-CH2-O-)2CH-CH2Br), 4.92 (s, 4H, C6H4-CH2-O-), 5.11 (t, 1H, (-CH2-O-)2CH-CH2-Br) and 7.18-7.24 (m, 4H, Ar). Synthesis of 5,6-benzo-2-methylene-1,3-dioxepane (BMDO) To a one liter round bottom flask equipped with a reflux condenser, 90 gram (0.37 mol) of 5,6-benzo-2-(bromomethyl)-1,3-dioxepane, 41.52 (0,37 mol) potassium tert-butoxide and 500 ml dry tert-butyl alcohol were added. The reaction was put under inert atmosphere and was heated to 80°C to maintain a gentle reflux. The reaction was left to run for 15 hours. After letting the reaction cool down, 500 ml of dry diethyl ether was added. The solid was filtered of over a celite column and solvent was removed under reduced pressure. The resulting product was purified by distillation under vacuum (typically at T=80°C and p=0,3 mbar). The liquid solidified upon standing and resulted in 50 gram (83%) of white crystals. Due to the possibility of degradation at atmospheric conditions, the product was stored under nitrogen atmosphere at -20°C. 1H-NMR (300 MHz; CDCl3): chemical shift (ppm) 3.71 (s, 2H, (-CH2O-)2CH=CH2), 5.06 (s, 4H, C6H4-CH2-O-), 7.06-7.09 (m, 2H, Ar) and 7.22-7.25 (m, 2H, Ar). Synthesis of methyl-2-(((octylthio)carbonothioyl)thio)propanoate (RA-1) To a 100 ml three neck flask equipped with a reflux condenser and dripping funnel, 1.2 ml (6.84 mmol) of octanethiol and 50 ml of chloroform were added. 1.14 ml (8.2 mmol) of triethylamine was added and the mixture was left to stir for one hour. Subsequently, 0.92 ml (8.2 mmol) of methyl-2-bromopropionate in 5 ml of CS2 was added dropwise to the reaction. During the addition, the mixture turned yellow to slightly orange. After the addition was completed, the reaction was left to stir overnight at room temperature. The mixture was quenched 56 ml of a 10 % HCl solution. The layers were separated and the organic layer was washed twice with 50 ml of water. The organic layer was dried over Na2SO4. After filtering off the solid, solvents were removed under vacuum, resulting in 1,835 gr (87 %) yellow/orange slightly viscous liquid. 1H-NMR (300 MHz; CDCl3): chemical shift (ppm) 0.85 (t, 3H,CH3-C7H14-), 1.25-1.32 (m, 10H, CH3-CH2-CH2-CH2-CH2-CH2-CH2-CH2-S-), 1.57 (d, 3H, CH3-CH-(S-CS-S-)(CO-O-CH3)), 1.66 (m, 2H, -CH2-CH2-CH2-S-), 3.32 (t, 2H, -CH2CH2-S-), 3.71 (s, 3H, CH3-O-CO-) and 4.82 (q, 1H, CS-S-CH-CH3-CO-O). Synthesis of pentaerythritol-tetrakis-(3-(S-methyl-2-propanoatotrithiocarbonyl) propanoate) (RA-4) The four functional Z-star RAFT agent was synthesized using the procedure from Boschman et al.. A 500 ml three neck flask was charged with 1.42 gr (5.89 mmol) of pentaerythritol-tetrakis(3mercaptopropionate and 200 ml of chloroform. Under stirring, 6.57 ml (47.1 mmol, 8 eq) triethylamine was slowly added to the flask. The reaction was left to stir for an hour at room temperature. Subsequently, 20 ml of CS2 and 5.26 ml (47.1 mmol, 8 eq) of methyl-2bromopropionate were added dropwise to the reaction after which the reaction as left to stir overnight. The reaction was then quenched by adding 200 ml of a 10 % HCl solution. Afterwards, the layers were separated and the organic layer was washed three times with 200 ml of water. The organic layer was dried over MgSO4. After removing the drying agent by filtration, the solvents were evaporated under vacuum. The residue, an orange/yellow viscous liquid, was purified by column chromatography using a 3:1 mixture of n-pentane/ethyl acetate as eluent. The product (4 gr (60%)) was obtained as an orange, highly viscous liquid. 1HNMR (300 MHz; CDCl3): chemical shift (ppm) 1.57 (d, 12H, CH3-CS-COOCH3), 2.77 (t, 8H, -O-CO-CH2-CH2-S-), 3.57 (t, 12H, -O-CO-CH2-CH2-S-), 4.10 (s, 8H, -C-CH2-O-CO-) and 4.80 (q, 4H, -S-CHCH3-CO-O-CH3). Figures A A B A B D C B C D A D B D C 8 C 7 6 5 4 3 2 1 ppm Figure S1 1H-NMR spectrum of BMDO and its hydrolysis degradation product that is formed upon exposure of the monomer to air. Figure S2 Synthesis route to 5,6-benzo-2-methylene-1,3-dioxepane (BMDO) 6000 Linear 4-arm star 5000 Mn /g·mol -1 4000 3000 2000 1000 0 0 2 4 6 8 t/h Figure S3 Number average molecular weight as a function of time in the linear RAFT copolymerization compared to the 4-arm star synthesis. Squares mark Mn from the linear polymerization, triangles denote star polymers 0.50 0.45 fMMA 0.40 0.35 0.30 0.25 0.20 0.15 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 xMMA Figure S4 Evaluation of the concentration data given in Figure 3 via the Skeist method resulting in r1 = 0.7 and r2 = 3.88. It should be noted that these values deviate slightly from the values obtained from the fit in Figure 4. While the Skeist method is per se very robust, is the current calculation based only on one experiment. The values calculated and discussed in the main text are based on a large number of experiments and are thus regarded as statistically more robust.