MEC325 - WEDM Lab Report Revised

advertisement

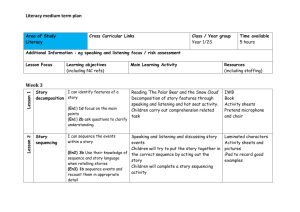

MEC325 Lab Report Wire Electrical Discharge Machine (WEDM) Date: March 26, 2014 Group Leader: Team Members: Matthew Stevens ID 108469622 Group Number: 20 Regiment No.: D Instructor: Dr. Qing Chang, Dr. Noah Machtay, Nikita Timofeev Department of Mechanical Engineering SUNY at Stony Brook 1 Table of Contents i. Objective………………………………………………..3 ii. Introduction…………………………………………......3 iii. Principles and Practice………………………………..3-4 iv. Design Procedures and Result………..…………………4 v. Conclusion…………………………………………….4-5 vi. Appendix……………………………………………...6-7 2 i. Objective The objective of this lab is to learn what a Wire Electrical Discharge Machine (WEDM) is, how to operate a WEDM, and write a G-codes, M-codes, and T-codes by hand that utilizes the unique features of a WEDM. ii. Introduction In the modern day of technology, manufacturing technologies has allowed for the improvement and advancement of our lives. Many products formerly not possible to make are now easy to mass produce under new manufacturing technologies. Traditional methods of machining in a lathe or milling machine are effective for softer metals and larger cuts that do not require high tolerance or small cuts. A wire electrical discharge machine excels for cutting any metal that conducts electricity regardless of hardness, smaller intricate shapes, and taper cuts, quicker, less expensive and more accurate solutions than conventional machining. Several main features make such a machine desirable. The most useful feature of the WEDM is the ability to cut hard materials since it is a non-contact cutting process. A WEDM cuts any material that conducts electricity by running a current through a thin wire. The wire creates microsparks that eats away at the metal. This process is entirely non-contact based, so the machine will cut any workpiece regardless of hardness. Some materials that would traditionally be difficult to machine using conventional machining methods like carbide, inconel, titanium, hastelloy are great uses for a WEDM. Next, since the WEDM only uses a wire, productivity time is faster since there is no need to change tools or finish the surface off. In fact, WEDM are great for creating burr free parts. Finally, the cutting wire is mounted on two separate heads that can move independently of each other, providing the WEDM with up to 5 axis cutting capabilities. Because of these features, WEDM is commonly used to time sensitive prototyping, parts with splines or high tolerances, large series production molds, and custom tool inserts. Not all machining jobs are best performed with a WEDM however. Since a wire is used to cut the material, all cuts must go through the material. If a design calls for a cut that stops midway in the part, then the WEDM will not be able to achieve this. iii. Principles and Practice Wire electrical discharge machining (WEDM), is a non-contact based operation that works using the principle of spark erosion to cut through often very hard materials like steel carbides, so long as those materials are electrically conductive. The setup involves two electrodes –one being a threaded wire for electricity to pass through and another being the work piece–immersed in dielectric fluid, fluid which normally acts as an insulator. If current is passing through the wire and if both the wire and work piece come close enough, the electric field in the volume of dielectric fluid between the two electrodes will exceed the strength of the dielectric and cause a voltage breakdown– a voltage at which the insulative dielectric fluid becomes conductive. [1] (Wiki Wire EDM) A small amount of material is vaporized from the work piece which will cool into solid particles and be flushed out by pressurized flow of the dielectric fluid. This phenomenon of spark erosion does not utilize the pressure contact-based methods of conventional machining using lathes, mills, and so on. If the wire and the work piece (the two 3 electrodes) do come into physical contact, passing current will only result in a short circuit and no useful spark erosion. In practice, for effective spark erosion in a WEDM machine, wire material and diameter, the type of dielectric fluid used, purification and de-ionizing of the dielectric fluid, “ON/OFF” duty cycle regulation, and so on must be optimized. Standard 0.0098” diameter brass wire was used and is most common, but brass-zinc, molybdenum, steel, and tungsten wires are used of sizes from 0.004” to 0.014”. [2] (Buhlmann Fundamentals) Brass offers a balance between conductivity, good tensile strength, and “flushability” which wire choice depends on. De-ionized water was used as the dielectric fluid. The dielectric fluid is cleansed of the solid particles from the work piece by a filter and of dissolved ions by what is often resin, which ensures it returns to its insulative behavior ready for the voltage breakdown during the next ON cycle. The “ON/OFF” duty cycle control the ON time the current is active and the OFF time when it is inactive and when flushing occurs, both in microseconds. To increase linear speed and reduce job time, ON time can be increased or OFF time can be decreased at the increased risk of wire breakage which is checked using the color bar of operation and verifying it’s at the edge of the green zone. [3] These factors can be accounted for in the “Condition Search” submenu and are listed as a header on top of the G-Code for the job. ON/OFF times can also be altered in real time. iv. Design Procedures and Results Our design objective was to create a tapered object resembling an I-Beam within our given 1”x” square, which we were able to accomplish by programming G-Codes for each independent head to create the entire part profile. Our strategy was to utilize the top head for tracing the top (larger) profile, with the bottom head tracing the bottom (smaller) profile. The wire was threaded arbitrarily at the vertical midsection of our work-piece, and then code was written to bring the wire into the desired position in the profile. This simplified our coding process, as we had to calculate coordinates for half the profile and used symmetry about the midsection to determine the remaining coordinates. For a detailed part drawing and complete listing of the G-Code used see Appendices A1 and A2. Our approach was successful in the lab, as our code produced the desired tapered profile. Specifically, our selection of the point where the wire was threaded was particularly useful when given an arbitrary 1”x”1 square within a larger piece of material. As we expected, our final product possessed the smooth tapered profile that we set to produce, with sharp edges forming the edges of the profile. The part came from the tank with very limited burrs and excess material, with the only noticeable excess occurring at the region where the threaded wire first started to trace the part profile. v. Conclusion Our approach to utilize the 4-Axis movement of the heads to design the taper was successful. We experienced first-hand the power and flexibility of WEDM machining, as our part was produced within 25 minutes with the intended design and a smooth burr-free finish. As expected, our final measurements were within the expected tolerances specified by the AQ300L WEDM Machine and possessed the smooth tapered profile between the top and bottom faces of the part. It is quite easy to see how proper utilization of this equipment can produce some of the complex part geometries, seemingly with ease and minimal error. 4 Our approach to utilize the 4-Axis movement of the heads to design the taper was successful. We experienced first-hand the power and flexibility of WEDM machining, as our part was produced within 25 minutes with the intended design and a smooth burr-free finish. As expected, our final measurements were within the expected tolerances specified by the AQ300L WEDM Machine and possessed the smooth tapered profile between the top and bottom faces of the part. It is quite easy to see how proper utilization of this equipment can produce some of the complex part geometries, seemingly with ease and minimal error. 5 vi. Appendix A1. CAD Drawing Dimensioned CAD Drawing of our design. 6 A2. G-Code the G-Code used to form the profile of our design. This code does not include the conditions that were implemented during the lab. G01 X0 Y0.125:G01 X0 Y0.175; G01 X-0.355 Y0.125:G01 X-0.275 Y0.175; G01 X-0.355 Y0.275:G01 X-0.275 Y0.275; G01 X-0.305 Y0.275:G01 X-0.225 Y0.275; G01 X-0.305 Y0.475:G01 X-0.225 Y0.475; G01 X-0.355 Y0.475:G01 X-0.275 Y0.475; G01 X-0.355 Y0.625:G01 X-0.275 Y0.575; G01 X0.355 Y0.625:G01 X0.275 Y0.575; G01 X0.355 Y0.475;G01 X0.275 Y0.475; G01 X0.305 Y0.475:G01 X0.225 Y0.475; G01 X0.305 Y.275:G01 X0.225 Y0.275; G01 X0.355 Y0.275:G01 X0.275 Y0.275; G01 X0.355 Y0.125:G01 X0.275 Y0.175; G01 X0 Y0.125:G01 X0 Y0.175; G01 X0 Y0:G01 X0 Y0; M02; CITATIONS [1] Jameson, E., 2001, Electrical Discharge Machining, Society of Manufacturing Engineers, Dearborn, MI, pp. 1. [2] Moulton, D., 2012, “Wire EDM – The Fundamentals”, http://www.buhlmann.be/worknews/fundamentals.pdf [3] Machtay, N., 2014, “Wire Electrical Discharge Machining Introduction: Sodick AQ300L”, http://mysbfiles.stonybrook.edu/~nmachtay/classes/mec325/wedmintro/index.html 7