food waste - DukeSpace

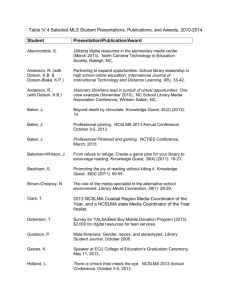

advertisement