An Investigation on the effect of temperature and

advertisement

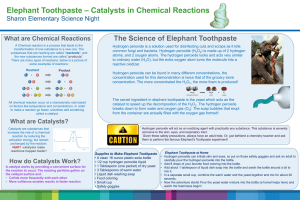

An Investigation on the effect of temperature and pH change on enzymatic decomposition of hydrogen peroxide An enzyme is a protein that speeds up chemical reactions by lowering the activation energy, acting as a catalyst to speed up the reaction rate. Enzymes are specific to specific substrates, and form an enzyme-substrate complex (see below). Enzyme function can be affected by several factors; usually by temperature, pH level, the concentration of the enzyme, the concentration of the substrate, and enzyme inhibitors. If the temperature or pH is too high, then the enzyme can be denatured. Denatured means loss of shape and function. Some of the most important enzymes are catalases. Catalases are biological enzymes produced by every cell to break down hydrogen peroxide. It is recognized that catalase function will be affected by pH and temperature, but at present, the optimal temperature and pH for catalase function have not been determined. Hydrogen peroxide (H2O2) is a strong oxidizing agent produced as a by-product of metabolism. It is a clear liquid that is commonly used as a cleaning agent or bleach. Hydrogen peroxide once was used to clean cuts, it has been recognized that it can cause oxidative damage to our cells.. Hydrogen peroxide is decomposed by catalases. The research objectives of this experiment were to determine the optimal temperature and pH for yeast catalase. The rate of catalase –mediated breakdown of hydrogen peroxide was measured at 3 different pH levels ((4, 7, and 10), and three different temperatures, (0 ºC, 22 oC and 60 oC). Two separate experiments were performed, one with temperature as the independent variable, the other with pH as the independent variable. The dependent variable measured in both tests was the change in oxygen produced in a closed chamber, through the catalasemediated decomposition of hydrogen peroxide. Enzyme substrate complex: Sources: http://seps.mgd-colo.peak.org/cvoracle/faq/catalase.html http://www.worthington-biochem.com/introBiochem/introEnzymes.html http://www.madsci.org/FAQs/catalase.html Materials and Methods: Since hydrogen peroxide is potentially damaging to skin and eyes, goggles were worn for the duration of the experiment. A Vernier® Oxygen Gas Sensor probe was connected to a Vernier Logger Pro® data collector, the apparatus was checked to confirm that it was working correctly. 1 200 ml of catalase solution was prepared by mixing 25 g of COOP™ yeast into lukewarm distilled water. Experiment 1: Effect of pH on the rate of decomposition of hydrogen peroxide The first experiment investigated the effect of pH change on the rate of decomposition of hydrogen peroxide. (Using a 2 ml measuring pipette), 5 ml of 3% hydrogen peroxide (H2O2) were measured into 3 25 ml test tubes (labelled pH4, pH7 and pH10). 5 ml of specific pH buffer (pH 4, pH 7 and pH 10) were added to each test tube. The pH of the buffer/ H2O2 mixture was measured using universal pH indicator. 2 ml of catalase was added to the test tube labelled pH 4, the mixture was transferred into a closed chamber and a stopwatch was started. 30 s after transfer, measurement of percentage oxygen was started using the Vernier® apparatus. Data collection was continued for 180 s. This procedure was repeated for the test tubes containing hydrogen peroxide/pH 7 and pH 10 buffer. Data was saved and transferred to EXCEL for the purpose of data analysis. Experiment 2: Effect of temperature on the rate of decomposition of hydrogen peroxide The second experiment investigated the effect of temperature change on the rate of decomposition of hydrogen peroxide. An ice bath was prepared and maintained at 0o C. 3% hydrogen peroxide, catalase solution and distilled water were maintained in the ice bath. Temperature was confirmed using a thermometer. Similarly, a hot water bath was prepared and maintained at 60o C. 3% hydrogen peroxide, catalase solution and distilled water were maintained in the hot water bath. Temperature was confirmed using a thermometer. (Using a 2 ml measuring pipette), 5 ml of 3% hydrogen peroxide (H2O2) were measured into 3 X 25 ml test tubes (labelled 0o C, 22o C and 60o C). 5 ml of distilled water were added to each test tube. 2 ml of catalase was added to the test tube labelled 0o C, the mixture was transferred into a closed chamber and a stopwatch was started. 30 s after transfer, measurement of % oxygen was started using the Vernier® apparatus. Data collection was continued for 180 s. This procedure was repeated for the test tubes containing hydrogen peroxide/22o C and 60o C. Data was saved and transferred to EXCEL for the purpose of data analysis. Results Table 1: The effect of pH change on the rate of oxygen produced by breakdown of hydrogen peroxide breakdown Reaction Rate No pH 7 pH 10 No Catalase pH4 2 peroxide 0.000 0.000 0.000 0.000 0 - 60 s 61 - 120 s 121 - 180 s 0 - 180 s 0.007 0.011 0.014 0.011 0.019 0.035 0.029 0.027 0.001 0.000 0.001 0.001 0.006 0.013 0.019 0.012 Figure 1: The effect of pH change on the rate of oxygen produced by breakdown of hydrogen peroxide The effect of pH change on oxygen produced by breakdown of hydrogen peroxide over time 25.00 24.00 23.00 No Peroxide 22.00 pH7 pH10 21.00 No catalase pH4 20.00 19.00 18.00 0 20 40 60 80 100 120 140 160 Figure 2: The effect of pH change on the rate of oxygen produced by breakdown of hydrogen peroxide 3 The effect of pH change on oxygen produced by breakdown of hydrogen peroxide over time 0.040 0.035 % oxygen 0.030 0.025 No peroxide 0.020 pH 7 0.015 pH 10 0.010 No Catalase 0.005 pH4 0.000 -0.005 0 - 60 s 61 - 120 s 121 - 180 s Time (s) 0 - 180 s Experiment 2: Table 2: The effect of temperature change on the rate of oxygen produced by breakdown of hydrogen peroxide Reaction Rate 0 - 60 s 61 - 120 s 121 - 180 s 0 - 180 s 0C 0.002 0.004 0.008 0.005 22 C 0.021 0.034 0.032 0.029 60 C 0.008 0.005 0.005 0.006 Figure 3: The effect of temperature change on the rate of oxygen produced by breakdown of hydrogen peroxide. 4 % oxygen% The effect of temperature change on oxygen produced by hydrogen peroxide breakdown 25.00 24.00 23.00 22.00 21.00 20.00 19.00 18.00 17.00 16.00 60 C 22 C 0C Linear (60 C) Expon. (22 C) 0 20 40 60 80 100 Time (s) 120 140 160 180 Linear (0 C) Figure 4: The effect of temperature change on the rate of oxygen produced by breakdown of hydrogen peroxide. % oxygen in closed chamber 0.040The effect of temperature on reaction rate of catalase-driven breakdown of hydrogen peroxide 0.035 0.030 0.025 0.020 0.015 0C 0.010 22 C 0.005 60 C 0.000 0 - 60 s 61 - 120 s 121 - 180 s Time from onset of reaction (s) 0 - 180 s 5 Discussion Figure 1 summarizes the effect of pH change on the rate of oxygen produced by breakdown of hydrogen peroxide. One might notice that when there is no peroxide or catalase, the oxygen production is very low and when the pH is at level 4 and/or 7, the oxygen production is moderate and they have around the same production rate. By looking at the graph, one can conclude that the best level of pH for yeast catalase is 10. Figure 2 summarizes the effect of pH change on the rate of oxygen produced by breakdown of hydrogen peroxide over time. It is evident that when there is a lacking of peroxide and catalase, the oxygen produced over time is at 0%. The catalase solution, when mixed with a pH of 4, produces oxygen at a fast rate. The fastest rate which oxygen was produced is from 121 to 180 seconds, producing an increase of 0.014% 𝑠 −1 oxygen and the lowest rate at which oxygen is produced is from 0 to 60 seconds, producing 0.019% 𝑠 −1 oxygen. The average rate at which oxygen is produced is 0.0125% 𝑠 −1 . The catalase solution with a pH of 7 produces oxygen at a slower rate. The fastest rate at which oxygen is produced is from 121 to 180, producing 0.0145% 𝑠 −1 of oxygen. The slowest rate at which oxygen is produced is during the fist minute, producing 0.007% 𝑠 −1 . The average oxygen produced is 0.011% 𝑠 −1 . The catalase solution with a pH of 10 proved to be best for oxygen production. It produced the most oxygen between 61 and 120 seconds, producing 0.035% 𝑠 −1 of oxygen, least during the first minute, producing only 0.019% 𝑠 −1 . Graph 3 demonstrates the results of the experiment for finding the effect of temperature change on the rate of oxygen produced by breakdown of hydrogen peroxide. By looking at the graph, a researcher observes that a 22 ° C is the optimal temperature for oxygen breakdown through yeast catalase. By looking at the results table, the researcher understands that the average percentage of oxygen production with a temperature of 22° C is 0.029% 𝑠 −1 , which is much higher than the production percentages of 60° C (which is 0.006%) and 0° C (which is 0.005% 𝑠 −1 ). Figure 4 displays the effect of temperature change on the rate of oxygen produced by breakdown of hydrogen peroxide. It is evident that the oxygen production was slowest at 0° C is the worst for oxygen production, 60° C is not much better, and that the rate of oxygen production was most rapid at 22° C. Over time, the rate of oxygen production remained relatively constant. It would have been good to consider the reasons for the different rates that were observed in the experiment; for example, the effect of temperature on the rate of collisions between enzyme and substrate molecules, the possibility of denaturation at 60 ºC, relative shape changes at different pH’s resulting in different affinities for the substrate. There are many possible sources of error throughout the experiments. The first is not preparing the correct measurements for the catalase solution. Instead of preparing 200 ml 6 of lukewarm, distilled water and mixing it with 25 g of COOP™ yeast to create the solution, the experimenters might have measured the water and/or yeast incorrectly. If there is too much yeast, the results will be altered and that is not acceptable and if there is too much or too little water, the results may also be altered. To prevent this error, the experimenters must be very careful whilst measuring the ingredients. The second source of error is the possibility of measuring the wrong amounts of hydrogen peroxide and pH. Using a 2 ml measuring pipette, 5 ml of 3% hydrogen peroxide (H2O2) were supposed to be measured into 3.25 ml test tubes. Then 5 ml of specific pH buffer (pH 4, pH 7 and pH 10) were to be added to each test tube. There is a chance that the scientists conducting these experiments added the wrong amount of hydrogen peroxide, which will affect the experimental results. There is also the possibility of incorrectly measuring the pH buffers and mixing up the solutions. If there is an incorrect amount of pH, then all of the results will be incorrect. If a scientist mixed up his/her pH solutions, then all of the results for each pH will be wrong and no one will know which results are correct, hence needing to re-do the entire experiment. To avoid this error, one must label each pH buffer, measure the pH buffers correctly and put the correct pH buffer in their assigned test tube. While transferring the mixture into a closed chamber a stopwatch was started for 30 seconds. 30 seconds after transfer, measurement of percentage oxygen began. The scientists could have messed up the experiment by starting the stopwatch too early or too late. Not starting at the correct time can affect the measurement collection. To make sure this error does not happen, a scientist must make sure that he/she is starting at the correct time. Another possible source of error is having misread and recorded incorrectly the initial percentage of oxygen. Having misread the oxygen percentage, the graphs’ data on the oxygen percentages will be incorrect. To prevent this error, the scientists need to make sure that the initial percentages of oxygen were recorded correctly and that the data was collected correctly. Conclusion This experiment shows the optimum temperature for oxygen production through yeast enzymes is 22° C and the best pH level is 10. 7