The CO 2 heat pump system consists of three double

advertisement

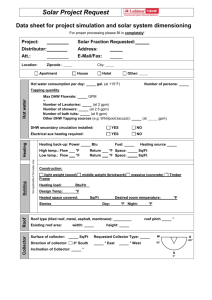

A Review on Performance Analysis of Hybrid Solar-Geothermal CO2 Heat Pump System for Residential Heating B. B Samantaray & A. Rout School of Mechanical Engineering, KIIT University, Bhubaneswar - 24, Odisha, India E-mail: bbsr .comofficial@gmail.com Abstract – A simulation study of hybrid solar-geothermal heat pump system for residential applications using carbon dioxide was carried out under different operating conditions. The system consists of a solar unit (concentric evacuated tube solar collector and heat storage tank) and a CO2 heat pump unit (three double-pipe heat exchangers, electric expansion valve, and compressor). As a result, the differential of pressure ratio between the inlet and the outlet of the compressor increases by 19.9%, and the compressor work increases from 4.5 to 5.3 kW when the operating temperature of the heat pump rises from 40 Cto 48 C. Besides, the pressure ratio of the compressor decreases from 3 to 2.5 when the ground temperature increases from 11 C to 19 C. The operating time of the heat pump is reduced by 5 h as the daily solar radiation increases.As the solar radiation increases from 1 to 20 MJ/m2, the collector heat rises by 48% and the maximum collector heat becomes 47.8 kWh. The heating load increases by 70% as the indoor design temperature increases from 18 C to 26 C. However, the solar fraction is reduced from 11.4% to 5.8% because of the increases of the heating load. I. pump using carbon dioxide is lower than that of a system using a subcritical cycle refrigerant because of large irreversibility during compression and cooling. Moreover, system reliability is very low due to large performance variations with operating conditions. II. SYSTEM MODELING The hybrid solar-geothermal CO2 heat pump system (HSG-CHPS) consists of a solar heat unit and a CO2 heat pump unit. The solar heat unit has a concentric evacuated tube collector, and a heat storage tank. The CO2 heat pump unit consists of two double-pipe heat exchangers (high- and low-temperature), a double pipe type evaporator, an electric expansion valve (EEV) and a semi-hermetic type reciprocating compressor (Q_cooling ¼ 10.55 kW). The heat source can divide into two parts; one is from solar and the other is from the heat pump. The heat source can divide into two parts; one is from solar and the other is from the heat pump. The heat is acquired by the collector is transferred to a thermal heat storage tank. A heat storage tank is controlled to maintain the designed temperature to supply for heating and hot water. INTRODUCTION Recently, hydrocarbon shortage and global energy crisis have aroused great interest in alternative energy supplies. This is especially true for South Korea that badly depends on imported energy resources. However, most alternative energy technologies are faced with difficulties when it comes to application for community facilities because of regional restrictions and operating cost. Therefore, researches on energy saving and optimal operation of residential heat pump systems are urgently required. To this end, using renewable energy (e.g. solar or geothermal) for refrigeration and air conditioning applications becomes increasingly important and draws considerable attention. As for working fluid, carbon dioxide is a natural climatefriendly refrigerant as it does not deplete ozone layer and has a low direct global warming potential with reference value 1. Generally, the performance of a heat 2.1. Solar collector and heat storage tank modeling The solar collector has eight concentric evacuated tube collectors, which can be reliably operated for getting heat for residential applications. As a working fluid water-propylene glycol mixture (water to propylene glycol ratio of 80:20) is used. The solar collector model was developed based on test results of the concentric evacuated tube collector by Korean Institute of Energy Research [13].In this study, the efficiency of the solar collector is calculated by ƞcollector = FRƮα - FRUL(Tin - TAir)/lt.. Where, IT, FR, FRsa, and UL are daily solar radiation, collector heat removal factor, intercept of efficiency curve, and collector ISSN (Print) : 2319 – 2526, Volume-2, Issue-1, 2013 31 Special Issue of International Journal on Advanced Computer Theory and Engineering (IJACTE) overall heat loss coefficient. Also, tin tair is the temperature difference between inlet temperature at the collector and ambient temperature. 2.3. Heat exchanger modeling The CO2 heat pump system consists of three double-pipe heat exchangers (high- and low-temperature gas cooler, evaporator), an EEV, and a reciprocating compressor of semi-hermetic type. In the heating mode, the double-pipe heat exchanger acts as an evaporator to exchange the heat between the refrigerant and the water supplied from the ground heat exchanger (GHX). Two double-pipe heat exchangers play the role of the gas cooler. The high temperature heat exchanger is placed at the compressor outlet. It exchanges the heat from hightemperature water to the middle of the heat storage tank so as to supply the hot water to the user. The low temperature double-pipe heat exchanger exchanges the heat from low-temperature water at the bottom of the heat storage tank to supply the mean temperature water for heating. From Table the specification of three kinds of double tube type heat exchanger. A tube-by-tube method was used to calculate the performance of the heat exchangers. 2.2. Compressor modeling Since the CO2 compressor is operated under high pressure, the semi-hermetic reciprocating compressor is selected as an analytical model. Generally, it shows high efficiency and reliability under high pressure conditions. The compression process was calculated by using volumetric efficiency, compression efficiency, and discharge temperature, which had been obtained and adjusted using Sanchez et al. [7] correlations. The compressor model of semi-hermetic reciprocating compressor has a displacement ð GÞ of 3.48 m3/h at 1450 rpm(N). The compressor work is obtained as a function of mass flow rate, compression efficiency(hc), the rate of heat transfer from the motor to the refrigerant ð QmotÞ, and enthalpy difference between inlet and outlet through the compressor. The compressor efficiency and mass flow rate are represented. . . 2.4. Simulation conditions To simulate the heating load for residential application, the indoor space was designed to have 66.25 m2. The heat loss through inner walls and floor is ignored, but losses through the roof and outside walls with windows are taken into account. Besides, the daily usage of the hot water was assumed to be 280 L for four-member family. The design parameters of heating load and hot water load are shown in Tables. Solar radiation was set by the average value in Korea during winter season and ground temperature was also set based on the average temperature on 5 m underground. The heat pump operating temperature means the heat pump start to supply the heat to a heat storage tank when the water temperature in the storage tank is reduced below the target temperature. Simulation conditions for this study are shown in Table. The simulation was performed and simulation results were obtained every 15 min. The EEV with a diameter of 1.6 mm is used as an expansion device for calculating the mass flow rate (Kim et al. [1]). In this study, the expansion process is assumed to be isenthalpic. The mass flow rate of the CO2 in EEV is calculated by using 6-physical and 4geometrical variables based on Buckingham p-theory. III. RESULTS AND DISCUSSION Since carbon dioxide is used as a transcritical cycle because of its low critical temperature, under normal operating conditions the gas cooling process occurs ISSN (Print) : 2319 – 2526, Volume-2, Issue-1, 2013 32 Special Issue of International Journal on Advanced Computer Theory and Engineering (IJACTE) above the critical temperature and pressure. Besides, system performance of a CO2 heat pump varies significantly according to operating conditions. Especially, it is strongly affected by gas cooling and evaporating conditions. Also, EEV opening of the CO 2 heat pump is one of the most important control factors to determine system performance because it affects the mass flow rate of the refrigerant and the compressor discharge pressure. Therefore, the optimal EEV opening is firstly investigated for the given operating conditions. Hence, the heating time is reduced by 2.7 h from 9.5 to 6.8 h as the heat pump operating temperature rises from 40 C to 48 C. 3.2. The effect of ground temperature on system performance The temperature and pressure at the inlet of the compressor increases as the ground temperature elevates. The compressor pressure ratio decreases and mass flow rate of the refrigerant increases because of high temperature and pressure of the evaporator. Hence, optimal EEV opening gets larger with an increase of ground temperature. Besides, the compressor outlet temperature decreases gradually as the compressor pressure ratio goes down. In this study, the compressor pressure ratio decreased from 3 down to 2.5 when ground temperature increased from 11 C to 19 C. The mass flow rate of the refrigerant increases from 62.5 to 81.4 g/s because the compressor pressure ratio decreases. In addition, the outlet temperature of the compressor decreased by 23 C. The elevation of the ground temperature can significantly reduce the refrigerant temperature at the outlet of the compressor that can improve system performance and reliability. 3.1. The effect of heat pump operating temperature on system performance The fig. shows variations of the compressor pressure ratio, optimal EEV opening, compressor work, and COP according to heat pump operating temperature. Since the heat pump operating temperature is one of big factors to system performance, the system performance was analyzed and investigated according to heat pump operating temperature. The optimal EEV opening decreases from 52% to 40% as the heat pump operating temperature increases from 40 C to 48 C. Besides, the heating COP decreases by 23.5% from 2.77.Fig. 3 shows variations of the heating time, heat pump operating time, collector heat, and solar fraction according to heat pump operating temperature. As the heat pump operating temperature increases, the temperature of the heat storage tank and gas cooler in the CO2 heat pump increases, simultaneously. For the given simulation condition, the hot water load is proportionally increased with heat pump operating temperature because the water with high temperature is used for hot water load. In addition, the supplying heat rate from the CO2 heat pump. However, the daily supplied heat is almost the same regardless of heat pump operating temperature because indoor heating load is designed with same heat load. In addition, the temperature of heating water supplied to the indoor heating unit (FCU, fan coil unit) is also increased with the increase of temperature in the storage tank. 3.3. The effect of daily solar radiation on system performance The collector operating time and collector efficiency simultaneously increases with increase of daily solar radiation. The collector efficiency increases up to 47.8% when daily solar radiation is 20 MJ/m2 compared to 0 MJ/m2. Especially, it increases dramatically when the daily solar radiation elevates from 1 to 5 MJ/m2. The rise of the collector operating time is directly related to the increase of the collecting heat gain at the solar collector. Moreover, it can increase heat supply to the storage tank. Otherwise, the pump operating time and heat pump heat are reduced. . Fig. 2: Schematics of analytical scheme for double tube heat exchange . ISSN (Print) : 2319 – 2526, Volume-2, Issue-1, 2013 33 Special Issue of International Journal on Advanced Computer Theory and Engineering (IJACTE) 3.4. The effect of indoor design temperature on system performance V. REFERENCES The Figure shows variations of solar fraction, collector heat, heating heat, and hot water heat according to indoor design temperature. As the indoor temperature increases, the heat loss of the indoor space increases due to the large temperature difference between the outdoor and indoor, resulting that the indoor heating load increases. However, the collector heat and the hot water load remain the same regardless of the variation of the indoor design temperature. This is because daily solar radiation and heat pump operating temperature are designed to be constant except the indoor design temperature for this analytic case. Therefore, the design of proper indoor temperature for variable outdoor conditions is very important in order to maintain high system performance and reliability in the hybrid solar-geothermal CO2 heat pump system. [1] W. Kim et al. / Renewable Energy 50 (2013) 596604,Published on 31.8.2012 in Sciencedirect.com. [2] Yumrutas R, Kunduz M, Ayhan T. Investigation of thermal performance of a ground coupled heat pump system with a cylindrical energy storage tank. International Journal of Energy Research 2003;27(11):1051e66. [3] Kuang YH, Wang RZ, Yu LQ. Experimental study on solar assisted heat pump system for heat supply. Energy Conversion Management 2003;44(7):1089e98. [4] Chiasson AD, Yavuzturk C. Assessment of the viability of hybrid geothermal heat pump system with solar thermal collectors. ASHREA Transactions 2003; 109(2):487e500. [5] Han Z, Zheng M, Kong F, Wang F, Li Z, Bia T. Numerical simulation of solar assisted ground-heat pump heating system with latent heat energy storage in severely cold area. Applied Thermal Engineering 2008;28(11&12):1427e36. [6] Kjellsson E, Hellstrom G, Perers B. Optimization of systems with the combination of ground-source heat pump and solar collectors in dwellings. Energy 2010;35(6):2667e73. [7] Wang E, Fung AS, Qu C, Leong WH. Performance prediction of hybrid solar ground-source heat pump system. Energy and Building 2011;47:600e11. [8] Xi C, Hongxing Y, Lin L, Jinggang W, Wei L. Experimental studies on a ground coupled heat pump with solar thermal collectors for space heating. Energy 2011;36(8):5292e300. [9] Chaturvedi SK, Mohieldin TO, Chen DT. Second-law analysis . Energy 1999;16(6):941e9. IV. CONCLUSION Performance characteristics of the hybrid solargeothermal CO2 heat pump system (HSG-CHPS) have been analyzed under varying operating conditions using a simulation model. The system consists of a solar unit (concentric evacuated tube solar collector and heat storage tank) and a CO2 heat pump unit (three doublepipe heat exchangers, electric expansion valve, and compressor .With solar radiation increase from 1 to 20 MJ/m2, the collector heat and the solar heat fraction rise by 48% and 22%, respectively. The maximum collector heat at daily solar radiation of 20 MJ/m2 is 47.8 kWh. The solar fraction increases by 5.7% on average per 5 MJ/ m2 rise of daily solar radiation. As the indoor design temperature rises from 18 C to 26 C, the heating load increases by 70%.However, the solar fraction reduces by 5.9% due to the rise of the heating load. Besides, the heat pump operating time rapidly increases. Therefore, the design of proper indoor temperature for variable outdoor conditions is very important in order to maintain high system performance and reliability in the hybrid solar-geothermal CO2 heat pump system. It was found that the performance of a CO2 heat pump can improve significantly by using solar and geothermal system and it can supply sufficient heat to the space during winter season. ISSN (Print) : 2319 – 2526, Volume-2, Issue-1, 2013 34