The effect of particle properties on froth stability of different ores

advertisement

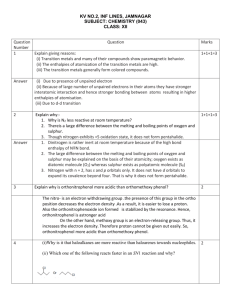

THE EFFECT OF PARTICLE SIZE ON FROTH STABILITIES OF DIFFERENT ORES ABSTRACT Belinda McFadzean*, Innocent Achaye, Jenny Wiese, Tadiwanashe Chidzanira, Martin Harris * Corresponding author: Centre for Minerals Research, University of Cape Town, Cape Town, South Africa, belinda.mcfadzean@uct.ac.za, +27216505528 Froth stability has an overriding effect on metallurgical recovery and grade for many ore types. Froth recoveries of less than 10% are common for low stability froths such as those in sparsely mineralized ores or in cells at the back end of flotation circuits. It is well known that, aside from chemical factors such as frothers and electrolytes, the mineral particles themselves have the dominant influence on froth stability. The particle properties of size and hydrophobicity are expected to have the greatest effects on froth stability. The aim of this study was to understand the effects of particle size on froth stability and to quantify these relationships. The study compared a synthetic ore of pyrite and quartz, with carefully controlled size ranges and hydrophobicity, with conventionally milled platinum-bearing UG2 ore and the bulk reverse flotation of hematite ore. A novel bench-scale continuous column flotation cell and continuous mechanical hybrid cell with large relative froth volumes, as well as a three-phase froth stability column were used to characterize the froths. It was found that froth stability could be related to the concentrate particle surface area by a Langmuir-type relationship. This is indicative that the mechanism by which particles stabilize the thin films in froths is similar to the mechanism by which surfactants lower surface tension. Different froth stabilities were found for different ores and this was thought to be the result of different particle sizes and distributions, which resulted in different packing densities in the thin films and Plateau borders. Interestingly, there was a clear relationship between the feed particle size and the froth stability even though froth stability was dependent on the concentrate particle surface area. It seems that the feed particle size is a good predictor of the surface area of particles in the concentrate. Concentrate particle size did not show a clear relationship with froth stability since it was already shown that it is both the size and the amount of the particles in the froth that contribute to the stability. 80 Synthetic ore UG2 ore Synthetic ore model UG2 ore model Froth stability (s) 70 60 50 40 30 20 10 0 0 10 20 30 Concentrate surface area (m2) 40 Figure 1 – Froth stability versus concentrate particle surface area. The markers are experimental data points and the lines are the fitted Langmuir-type model. KEYWORDS Froth stability, particle size, particle hydrophobicity