polb23373-sup-0001-suppinfo

advertisement

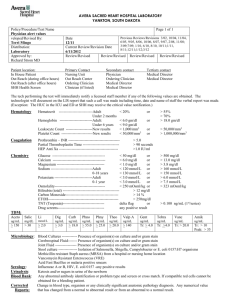

Supplementary Material Crystallization and Melting of Poly(glycerol adipate) Based Graft Copolymers with Single and Double Crystallizable Side Chains Dirk Pfefferkorn,† Martin Pulst,† Toufik Naolou,† Karsten Busse,† Jens Balko,‡ Jörg Kressler*,† † Department of Chemistry, Martin Luther University Halle-Wittenberg, D-06099 Halle(Saale), Germany ‡ Department of Physics, Martin Luther University Halle-Wittenberg, D-06099 Halle(Saale), Germany * Corresponding author E-mail: joerg.kressler@chemie.uni-halle.de Polymer Synthesis Synthesis of Poly(glycerol adipate) PGA. Ploy(glycerol adipate) was synthesized enzymatically using glycerol and divinyl adipate as monomers according to the procedure described by Kallinteri et al.1 Synthesis of alkyne modified poly(glycerol adipate) PGA-alkyne. PGA (1.5 g, 7.41 mmol with respect to OH groups) and 5-hexynoic acid (2.1 ml, 18.5 mmol) were dissolved into 20 ml dichloromethane (DCM) and added to an oven dried 100 ml two-necked round bottom flask. The mixture was cooled using an ice bath. Afterwards, a solution of 4-(dimethylamino)pyridin (DMAP) (293 mg, 0.96 mmol) and dicyclohexylcarbodiimid (DCC) (3.44ml, 14.85 mmol) dissolved into 10 ml of DCM was dropwise added to the polymer solution over 20 min. The mixture was stirred at room temperature for 24 h and yields finally a brownish solution. The solution was then filtered to remove the resulting precipitate. The organic solution was then extracted three times using distilled water. The organic layer was dried by anhydrous sodium sulfate. The polymer was further purified by precipitation into cold n-hexane two times followed by drying at 40°C. The 1H NMR spectrum of PGA-alkyne in CDCl3 is given in the Figure S1. The integral ratio between peak a and peak d is 4 : 0.97 which means nearly quantitative coupling. Synthesis of Poly(glycerol adipate)-g-Poly(ethylene oxide) PGA-g-PEO. PGA-alkyne (150 mg, 0.51 mmol with respect to alkyne group) and azide-terminated poly (ethylene glycol) monomethylether (1.2 mg, Mn=2000 g/mol, 0.56 mmol) were dissolved into 3.5 ml anhydrous dimethylformamide (DMF) and then loaded 10 ml oven dried Schlenk flask. Degassing was carried out by bubbling nitrogen for 15 min. This was followed by addition of (21 mg, 0.15 mmol) of CuBr and (0.031 ml, 0.15 mmol) of N,N,N′,N′′,N′′-pentamethyldiethylenetriamine (PMDETA). Further degassing was carried out again using nitrogen for 10 min. The solution was kept for 37 h at room temperature. The reaction was quenched by open the rubber septum for 30 min. The solution was then diluted using tetrahydrofurane (THF), and purified using a silica gel column in order to remove cupper bromide. This was followed by removing solvent using rotary evaporation at 40 °C under vacuum. The residue was redissolved using 10 ml methanol followed by dialysis against water for four days using regenerated cellulose membrane MWCO= 3500 Da. The polymer was finally dried by freeze drying. Figure S2 shows the 1H NMR spectrum of PGA17-g-PEO44 in CDCl3. The grafting efficiency was calculated by calculating the integrate ratio between peak m and peak d which was 3 : 0.97. Thus, the reaction was almost quantitative within the experimental error of 1H NMR spectrascopy. Furthermore, the comparison between the FT-IR spectra of PGA17-alkyne and PGA17-g-PEO44 reveals a complete disappearance of alkyne vibration of PGA17-alkyne at 650, 2115, and 3290 cm-1 as a result of the coupling reaction Figure S3. Synthesis of poly(glycerol adipate)-g-poly(ε-caprolactone) PGA-g-PCL. The typical procedure to synthesize PGL-g-PCL is described here briefly; PGA (Mn= 3400 g/mol, 1 mmol with respect to hydroxyl group), ε-caprolactone (25 mmol) and stannous octoate (0.027 ml) were dissolved in 10 ml of anhydrous THF and charged in 25 ml oven dried Schlenk tube. The solution was degassed and stirred for 20 h. The solution was then concentrated and precipitated into 200 ml of methanol. Precipitation in methanol was repeated many times in order to remove the inevitably generated homopolymer poly(ε-caprolactone).2 Synthesis of alkyne-modified poly(glycerol adipate)-g-poly(ε-caprolactone), PGA-g(PCL-alkyne). PGA-g-PCL (Mn= 32000 g/mol, 0.52 mmol) and 5-hexynoic acid (0.13 ml, 1.15 mmol) were dissolved into 25 ml of anhydrous dichloromethane (DCM) and added to 100 mL round bottom flask. The solution was then cooled using ice bath. A solution of 1-ethyl-3-(3dimethylaminopropyl)carbodiimide (EDCI) (1.15 mmol) and DMAP (0,23 mmol) dissolved into 7 ml DCM was then dropwise added to the cooled solution. The mixture was stirred for 24 h at ambient temperature. The resulting solution was filtered to remove the precipitate. The polymer solution was then precipitated two times into cold diethyl ether and dried under vacuum at room temperature. Synthesis of PGA-g-(PCL-b-PEO) using “click” chemistry. Briefly, PGA-g-PCL (Mn=32000 g/mol, 0.29 mmol), azido-terminated poly(ethylene oxide) monomethylether (mPEO-N3) (Mn= 2000 g/mol, 0.3 mmol), and PMDETA (0.2 mmol) were dissolved into anhydrous DMF and added to 25 ml Schlenk tube. The tube was degassed for 10 min. Then (0.2 mmol) of CuBr was added. The solution was agitated for 48 h at ambient temperature. The polymer solution was passed then through alumina column to remove CuBr. The resulting solution was concentrated and dialyzed against water for 4 days using dialysis membrane of MWCO= 3500 g/mol. The product was dried by freeze-drying. Synthesis of -Hydroxy--Alkyne End Functional Poly(ε-caprolactone) (AlkynePCL).The polymer was synthesized according to the procedure described by Hoogenboom et al. 3 The reaction was carried out at 85 °C. Synthesis of Poly(ε–caprolactone)-b-Poly(ethylene oxide) PCL-b-PEO. Alkyne-PCL (Mn=1800 g/mol, 0.4 mmol), mPEO-N3 (Mn= 2000 g/mol, 0.4 mmol) were dissolved into 20 ml anhydrous DMF and added to oven dried Schlenk tube. The tube was purged with nitrogen for 10 min. CuBr (16 mg, 117 mmol), PMDETA (0.024 ml, 117 mmol) were then added. The solution was purged again with nitrogen for 10 min. afterwards; the solution was kept at room temperature for 2 d. At the end resulting solution was passed through alumina column in order to remove copper bromide. The resulting solution was dialyzed against acetone for 2 d using dialysis membrane of MWCO= 2000 g/mol. Finally, the resulting polymer was dried in an oven at 50 °C under vacuum. FigureS1. 1H NMR of PGA17-alkyne in CDCl3 at 400 MHz. Figure S2. 1H NMR spectrum of PGA17-g-PEO44 in CDCl3 at room temperature and 400 MHz. Figure S3. FT-IR spectra of PGA17-alkyne and PGA17-g-PEO44. Figure S4. The WAXD pattern of PEO44 and PGA17-g-PEO44. Figure S5. SAXS traces of PCL16. Figure S6. The SAXS patterns of PGA17-g-PCL15. Figure S7. The SAXS patterns of PGA17-g-PCL25. References (1) Kallinteri, P.; Higgins, S.; Hutcheon, G. A.; St Pourçain, C. B.; Garnett, M. C. Biomacromolecules 2005, 6, 1885–1894. (2) Aoi, K.; Aoi, H.; Okada, M. Macromol. Chem. Phys. 2002, 203, 1018–1028. (3) Hoogenboom, R.; Moore, B. C.; Schubert, U. S. Chem. Commun. (Cambridge, U. K.) 2006, 4010–4012.