Lipid extraction procedure

advertisement

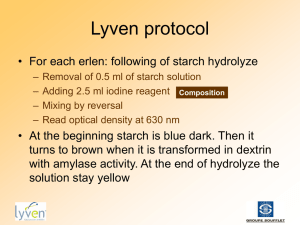

Standard Operating Procedure Total starch extraction procedure Department: Agronomy Created by: Gerald Sebuwufu Laboratory: Crop Production & Physiology Supervisor: Dr. Mark Westgate Lab Supervisor: Whitney Bouma Date approved: Procedure Overview: Lipid extraction of neutral lipids carried out using hexane. Equipment: 1. 2. 3. Glass test tubes (round bottomed; 16 x 120 mm or 18 x 150 mm). Micro-pipettors, 100 μL (e.g. Gilson Pipetman® or Rainin EDP-2® motorized dispenser). Positive displacement pipettor e.g. Eppendorf Multipette® - with 50 mL Combitip® (to dispense 3 mL aliquots of bacterial α-amylase solution). - with 5.0 mL Combitip® (to dispense 0.1 mL aliquots of amyloglucosidase solution). 4. Bench centrifuge (required speed 3,000 rpm; approx. 1,800 g). 5. Analytical balance. 6. Spectrophotometer set at 510 nm. 7. Vortex mixer (e.g. IKA® Yellowline Test Tube Shaker TTS2). 8. Thermostated water bath set at 50°C. 9. Boiling water bath with tube rack. 10. Stop clock 11. -20C freezer Reagents Total Starch Kit – http://secure.megazyme.com/Total_Starch_AA_AMG Contains: 1. Bottle 1: Thermostable α-amylase (10 mL, 3,000 U/mL on Ceralpha reagent* at pH 6.5 and 40°C or 1600 U/mL on Ceralpha reagent at pH 5.0 and 40°C). Stable for > 4 years at 4°C. 2. Bottle 2: Amyloglucosidase (10 mL, 3300 U/mL on soluble starch (or 200 U/mL on p-nitrophenyl β-maltoside*) at pH 4.5 and 40°C. Stable for > 4 years at 4°C. 3. Bottle 3: GOPOD Reagent Buffer. Buffer (48 mL, pH 7.4), p-hydroxybenzoic acid and sodium azide (0.4 % w/v). Stable for > 4 years at 4°C. 4. Bottle 4: GOPOD Reagent Enzymes. Glucose oxidase plus peroxidase and 4-aminoantipyrine.Freeze-dried powder. Stable for > 5 years at -20°C. 5. Bottle 5: D-Glucose standard solution (5 mL, 1.0 mg/mL) in 0.2 % (w/v) benzoic acid. Stable for > 4 years at room temperature. 6. Bottle 6: Standardized regular maize starch control. Starch content shown on vial label. Stable for > 4 years at room temperature. Other reagents needed i. Sodium acetate buffer (100 mM, pH 5.0) plus calcium chloride (5 mM). ii. Sodium acetate buffer (1.2 M, pH 3.8). iii. Potassium hydroxide solution (2 M). iv. Ethanol (80% v/v) March/25/20131 Protocol: Determination of total starch content of samples containing resistant starch, but no D-glucose and/or maltodextrins (KOH Format - Recommended). 1. Mill bean seed (dried at 60oF for 48hrs) to pass a 0.5 mm screen. 2. Add milled sample (~100 mg, weighed accurately) to a glass tube (16 x 120 mm). 3. Wet with 0.2 mL of aqueous ethanol (80 % v/v) to aid dispersion, and stir the tube on a vortex mixer. 4. Add a magnetic stirrer bar (5 x 15 mm) and 2 mL of 2 M KOH to each tube and re-suspend the pellets (and dissolve the RS) by stirring for approx. 20 min in an ice/water bath over a magnetic stirrer (Figure 1). i. ii. iii. NOTE: Do not mix on a vortex mixer as this may cause the starch to emulsify. Ensure that the tube contents are vigorously stirring as the KOH solution is added. This will avoid the formation of a lump of starch material that will then be difficult to dissolve. 5. Add 8 mL of 1.2 M sodium acetate buffer (pH 3.8) to each tube with stirring on the magnetic stirrer. Immediately add 0.1 mL of thermo stable α-amylase (bottle 1) and 0.1 mL of AMG (bottle 2), mix well and place the tubes in a water bath at 50°C. 6. Incubate the tubes for 30 min with intermittent mixing on a vortex mixer. 7. Quantitatively transfer the contents of the tube to a 100 mL volumetric flask (using a water wash bottle). Use an external magnet to retain the stirrer bar in the tube while washing the solution from the tube with a water wash bottle. Adjust to 100 mL with distilled water and mix well. Centrifuge an aliquot of the solution at 1,800 g for 10 min. 8. Transfer duplicate aliquots (0.1 mL) of the diluted solution to the bottom of glass test tubes (16 x 100 mm). 9. Add 3.0 mL of GOPOD Reagent to each tube (including the D-glucose controls and reagent blanks), and incubate the tubes at 50°C for 20 min. 10. D-Glucose controls consist of 0.1 mL of D-glucose standard solution (1 mg/mL) and 3.0 mL of GOPOD Reagent. Reagent Blank solutions consist of 0.1 mL of water and 3.0 mL of GOPOD Reagent. 11. Read the absorbance for each sample, and the D-glucose control at 510 nm against the reagent blank. 12. CALCULATIONS (Solid samples): 13. Starch, % = ΔA x F x FV/0.1 x 1/1000 x 100/W x 162/180 = ΔA x F/W x FV x 0.9 where: ΔA = Absorbance (reaction) read against the reagent blank. F = 100 (μg of D-glucose) (conversion from absorbance for 100 μg of glucose absorbance to µg) FV = Final volume (i.e. equals 100 mL or 10 mL) 0.1 = volume of sample analyzed. 1/1000= Conversion from μg to mg. 100/W= Factor to express “starch” as a percentage of flour weight. W = The weight in milligrams (“as is” basis) of the flour analyzed. 162/180= Adjustment from free D-glucose to anhydro D-glucose (as occurs in starch). 14. Starch % w/w (dry wt. basis): = Starch % w/w (as is) x 100/100-moisture content (%w/w) Personal Protective Equipment / Engineering Controls: Eye protection (goggles & shield) Skin protection (proper shoes, nitrile gloves, lab coat, etc.) Ventilation system Safety shower Eye wash station Hazard Controls & Storage Precautions: 1. α-amylase Precautions for safe handling Avoid contact with skin and eyes. Avoid formation of dust and aerosols. Provide appropriate exhaust ventilation at places where dust is formed. Conditions for safe storage March/25/20132 Keep container tightly closed in a dry and well-ventilated place. 2. Amyloglucosidase- from Aspergillus niger Precautions for safe handling User Exposure: Avoid contact with eyes, skin, and clothing. Avoid inhalation. Avoid prolonged or repeated exposure. Conditions for safe storage Suitable: Keep tightly closed. Store away from heat. Store at 2-8°C 3. p-hydroxybenzoic Precautions for safe handling Avoid contact with skin and eyes. Avoid formation of dust and aerosols. Provide appropriate exhaust ventilation at places where dust is formed. Normal measures for preventive fire protection. Conditions for safe storage Keep container tightly closed in a dry and well-ventilated place. 4. Glucose oxidase/peroxidase reagent Precautions for safe handling Provide appropriate exhaust ventilation at places where dust is formed. Normal measures for preventive fire protection. Conditions for safe storage Keep container tightly closed in a dry and well-ventilated place. Recommended storage temperature: 2 - 8 °C 5. 4-aminoantipyrine Precautions for safe handling Avoid contact with skin and eyes. Avoid formation of dust and aerosols. Provide appropriate exhaust ventilation at places where dust is formed. Normal measures for preventive fire protection. Conditions for safe storage Keep container tightly closed in a dry and well-ventilated place. hygroscopic Light sensitive. 6. D-Glucose standard solution Conditions for safe storage Keep container tightly closed in a dry and well-ventilated place. Recommended storage temperature: 2 - 8 °C 7. Ethanol Precautions for safe handling Avoid contact with skin and eyes. Avoid inhalation of vapour or mist. Use explosion-proof equipment. Keep away from sources of ignition - No smoking. Take measures to prevent the buildup of electrostatic charge. Conditions for safe storage Keep container tightly closed in a dry and well-ventilated place. Containers which are opened must be carefully resealed and kept upright to prevent leakage. Hygroscopic. 8. Sodium acetate- Keep container tightly closed in a dry and well-ventilated place. 9. Potassium hydroxidePrecautions for safe handling Avoid contact with skin and eyes. Avoid formation of dust and aerosols. Provide appropriate exhaust ventilation at places where dust is formed. Conditions for safe storage Keep container tightly closed in a dry and well-ventilated place. Absorbs carbon dioxide (CO2) from air. Air sensitive. Strongly hygroscopic 10. Sodium Azide Precautions for safe handling Avoid contact with skin and eyes. Avoid formation of dust and aerosols. Provide appropriate exhaust ventilation at places where dust is formed. Conditions for safe storage Keep container tightly closed in a dry and well-ventilated place. March/25/20133 Never allow product to get in contact with water during storage. Do not store near acids. 11. Waste Disposal Procedures & Decontamination: All excess solutions will be put in a safe bottle for disposal by EH&S. Discharge into the environment must be avoided. March/25/20134 Health & Safety Info for Required Reagents: C a r c i n o g e n T e r a t o g e n C o r r o s i v e T o x i c I r r i t a n t S e n s i t i z e r H i g h l y T o x i c Chemical name Sodium azide Sodium acetate Potassium hydroxide 3 Kit reagents α-Amylase Amyloglucosidase p-hydroxybenzoic Glucose oxidase/peroxidase reagent 4-aminoantipyrine 3 2 3 C o m b u s t i b l e Target Organ Heart, Central nervous system, Brain. Skin, eyes Tissue of the mucous Membranes and upper respiratory tract. Skin, Eyes, digestive tract C o m p r e s s e d G a s E x p l o s i v e F l a m m a b l e O r g a n i c P e r o x i d e s P y r o p h o r i c U n s t a b l e W a t e r R e a c t i v e H e a l t h F l a m m a b i l i t y R e a c t i v i t y 4 0 0 1 3 1 0 0 1 2 2 2 0 0 0 0 0 0 0 0 0 Incompatibilities Nitro compounds, Organic materials, Magnesium, Copper, Water, reacts violently with:, Metals, Light metals, Contact with aluminum, tin and zinc liberates hydrogen gas. Contact with nitromethane and other similar nitro compounds causes formation of shock-sensitive salts., vigorous reaction with:, Alkali metals, Halogens, Azides, Anhydrides Skin, eyes Oxidizing agents 3 Skin, eye, respiratory Skin, eye, respiratory Strong oxidizing agents 4 Skin, eye, respiratory Strong oxidizing agents, Strong acids, Acid chlorides, Acid anhydrides Strong bases, Strong oxidizing agents, Strong reducing agents 2 0 0 0 0 0 Alkali metals, Ammonia, Oxidizing agents, Peroxides 0 3 0 D-Glucose standard solution Ethanol O x i d i z e r Skin, eye, respiratory The above summary consists of guidelines for proper handling & disposal of chemicals used in this procedure. You must read attached MSDSs for more specific information before using the procedure. References Megazyme International Ireland. 2011. Total starch assay procedure (Amyloglucosidase/ α- Amylase method) http://secure.megazyme.com/files/BOOKLET/K-TSTA_1107_DATA.pdf Sigma-Aldrich. 2012. Material Safety Data Sheets- http://www.sigmaaldrich.com March/25/20135