Progress Report 2

advertisement

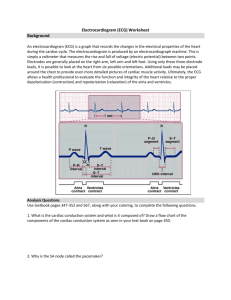

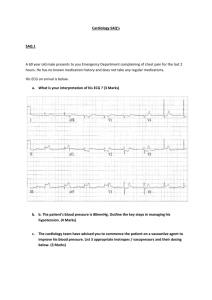

Created by: ECE 480 Design Team 6 Attention: Dr. S. Ratnajeevan H. Hoole Subject: ECG Demonstration Board Solution Progress Report 2 Date: November 20th, 2012 Statement of Purpose This progress report was created to provide the reader an understanding of the work accomplished towards the completion of an Electrocardiograph (ECG) demonstration board for Texas Instruments. This progress report outlines work accomplished since our previous progress report delivered on October 25th. We are currently on schedule, and this report outlines the technical work completed, nontechnical work completed, as well as remaining technical work to be done. The schedule for the remaining work has changed from that set at the beginning of the semester due to the extended fabrication and shipping time of our final PCB design. Most of the remaining work will be completed during Design Day week once our Advanced Circuits board arrives. Technical Work Completed Designed the ECG schematic We built our ECG schematic from scratch based on PowerPoint slides provided by Mr. Semig, and our own research and feedback from Mr. Semig after each draft. For schematics, we drew the original schematic in TINA-TI then transfered it to PCB Artist. The TINA-TI schematic is for simulations and the PCB Artist schematic creates a correlation between the schematic and layout views. The circuit was built using the INA333, TPS5410 and OPA2333. These chips were available as free samples from Texas Instruments (TI). The ECG schematic underwent three revisions before being transferred into a layout. The PCB Artist schematic is attached as the second to last page of this report. The revisions included adding common node voltage capacitors to the input of the INA333, an RC filter and active filter to the output, RC filters to the input, a 9V step down low-dropout (LDO) power supply using the TPS5430, switching the TPS5430 to the 5410 for better efficiency and ease of soldering, and adding decoupling capacitors between power and ground. Designed the ECG layout The ECG layout was built from our schematic and is currently ordered. We are awaiting arrival of the board to populate and test performance. The layout underwent one official revision through Mr. Semig, which he felt was sufficient due to the minor changes needed to be made. Mr. Semig told us to check the total current our LDO power supply needed to supply the op-amps (OPA2333) and instrumentation amplifier (INA333), and try to increase efficiency. We had to filters at the output to select between. One filter was active; the other was passive. However, we did not place jumpers at each end of the filter, so we added additional jumpers. This afforded us the ability to isolate the filter we were not using. He also wanted op-amps moved closer to the source of their signals. This helps to decrease possible interference to the signal. Finally, he suggested adding the battery directly onto the board and cutting the ground plane out beneath the chips inverting nodes. Cutting the ground plane beneath the inverting nodes prevents current from running through the ground plane underneath these nodes. As these are sensitive areas of our circuit, preventing interference from current in the ground plane to these nodes is worth increasing ground plane impedance by cutting notches under the nodes. These changes may sound extensive and severe, but they were mostly minor adjustments made on the layout. After all changes had been made, we all looked the layout over and ordered it. The finished layout is attached as the last page of this document. Ordered the INA333, OPA2333, and TPS5410 We ordered free samples of all the chips needed to populate our ECG printed circuit board (PCB). We have not ordered the components because our layout was finished and ordered on 11/19. Now that our layout is finished, we have final component values and will order them shortly. This is not an issue because components arrive quicker than our ECG PCB will. Tested CardioSim2 with the oscilloscope We are currently testing inputs and outputs with the CardioSim2. The CardioSim2 can be connected to at ten points. Each point represents an area of the body where an electrode is attached in a 12-lead ECG machine. A lead is a pairing of electrodes that produces a voltage signal useful to mapping activity. So, a 12-lead ECG uses the 12 informative pairings of these ten electrodes. CardioSim2 provides the electrodes to simulate up to these 12-lead ECGs as well as heart irregularities like an arrhythmia. Our board will be a three lead ECG, so we only need to worry about the signals pertinent to a three lead ECG. These include the Right Leg (RL), Right Arm (RA), and Left Arm (LA) electrodes. The pairings are RA RL, RA LA, and RL LA. We tested all of these pairings and only received noise. When we fed a signal from the function generator through the Right Leg, we read the signal at the right and left arms. However, the voltage difference was still zero. Since ECGs map the heart using the voltage difference between the RA and LA, we are not getting correct results. Additionally, we tried pairings of electrodes used in 12-lead ECGs and even abnormalities like an arrhythmia. Nothing produced correct results. Online documentation only exists for CardioSimVII. So, we have talked to Mr. Semig and will continue testing. Currently, the CardioSim does not work. Non-Technical Work Completed Application Note Each group member wrote an individual application note, which was turned in to our facilitator Professor Hoole. Following is each group member’s topic. Matt Affeldt’s topic was electrical considerations when creating a printed circuit board (PCB) layout. Derek Brower’s topic was creating a layout in PCB Artist. Phil Jaworski’s topic was using TINA-TI simulation software. Jung-Chung Lu’s topic was creating a library and component in PCB Artist. Alex Volinski’s topic was electrocardiography and design. Technical Presentation Our group gave a technical presentation on printed circuit board (PCB) design. Topics covered in the presentation included layout, assembly, and electrical considerations as well as software flow. Software flow covered the basics of designing a PCB schematic and layout in software. Layout considerations discussed floor planning, routing, and board options available to a PCB designer. Assembly considerations examined component types and assembly techniques. Finally, electrical considerations covered material important to more advanced PCB designs including impedance tradeoffs, antennas, and stray capacitance. Remaining Technical Work Determine how the CardioSim2 functions We need to determine how to receive the correct outputs for signals of the heart from CardioSim2. This is essential because CardioSim2 will supply the inputs and Right Leg Drive to our ECG board. Order components to populate ECG The resistors, capacitors, diodes, inductors, and test points necessary to populate our ECG need to be ordered. The chips are already on order. Populate and test the ECG Upon receiving our board and components, we need to solder the board together and run simulations using CardioSim2. The results will be a large part of our final presentation on Design Day and our final written report. Organize the data and incorporate it into our final report and presentation The results of our ECG tests must be organized and analyzed. The results of this will be incorporated into the final reports for the class. Important Parts to be Used Part Manufacturer Quiescent Current Supply Voltage (Vs) Input Voltage Range Part Manufacturer Quiescent Current Supply Voltage (Vs) Input Voltage Range Part Manufacturer Max Output Current Max Efficiency Input Voltage Range OPA2333 Texas Instruments 50 uA 7 Vmax -0.3V to 0.3V OPA2333 Texas Instruments 17 uA 1.8V to 5.5V -0.1V to 0.1V TPS5410 Texas Instruments 1.0 Amphere (continuous) 95% 5.5V to 36V Final ECG Schematic Final ECG Layout