Health, Safety and Work Environment Branch

advertisement

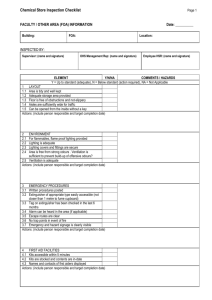

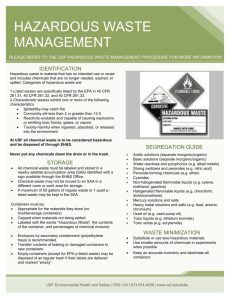

ANU Workplace Inspection Program Inspection Reference Sheet – Workshops WA. General safety WA.1 The workshop is a designated Hazardous Location and signed accordingly WA.2 Risk assessments are available for all: Plant, machinery, equipment Tasks within the workplace WA.3 Safe operating instructions (Safe Work Method Statements) are available and current for plant, machinery, equipment and tasks WA.4 Training or competency for equipment is covered at induction and thereafter at regular intervals as determined by management as appropriate WA.5 A list of trained or competent operators is available for high risk equipment as defined in the University’s Workshop and Trade Safety notes. WA.6 Warning signs for hazards are prominently posted (eg eye protection) WA.7 Working alone and/or out-of-hours procedure(s) and authorisation is documented WA.8 Health Surveillance has been discussed with staff and students WA.9 Key safety documents (eg protocols, assessments, contact lists etc) have version number; date and author details (document control). WB. Housekeeping WB.1 Benches are occupied only by chemicals/equipment ‘in use’ WB.2 Storage of heavy items above shoulder height is avoided WB.3 Aisles/exits are clear WB.4 Spill kits, supplies and decontamination material are available for the hazards present WC. Floors WC.1 Floors are clean and free from slipping and tripping hazards, e.g. spilt liquid, swarf, material offcuts, damaged floor surfaces WC.2 Floors that are not insulated are provided with footboards, mats or similar protection for operators at benches and other workstations WC.3 Storage of items on floors is kept to a minimum WD. Machinery/equipment WD.1 Machines are appropriate for use in the workplace in which they are installed, e.g. flame proof wiring, floor loading considerations, noise, vibration, etc WD.2 Machines are constructed and installed in accordance with relevant Australian Standards WD.3 Machines are guarded to protect operators and others from harmful contact, entanglement, flying objects, etc. and to prevent damage to property ANU WHS Workplace Inspection – Workshops Work Environment Group HR Division Version 5: 1/2014 Page 1 of 7 WD.4 Plant, machinery and equipment are provided with: Emergency stops Isolation and lockout devices Appropriate guards WD.5 Starting, stopping and warning devices are within easy reach of the operator WD.6 There is sufficient clearance around machines for operators and general movement within the proximity of the machines: For operators, not less than 1000 mm, Non-operating space adjacent to machines, not less than 800 mm WD.7 Equipment task lighting is of extra low voltage (typically 12 to 32 V) WD.8 Operation manuals/guidelines are available which include safety directions WD.9 A maintenance logbook is available and used WD.10 Materials handling devices, including trolleys, pallet trucks, lift trucks etc. are provided (when necessary), inspected (at least annually) and maintained in good condition. Appropriate records are kept. WD.11 Lifting equipment (hoists, cranes) and associated tackle are regularly inspected and maintained. Appropriate records are kept. WD.12 Lifting tackle (slings, spreader bars etc) are regularly inspected and maintained. Appropriate records are kept. Items are within retest dates. WD.13 Ovens and furnaces are fitted with flues or extraction hoods to remove fumes and heat WD.14 Portable ladders, including stepladders, extension ladders and trestle ladders, are in good condition and correctly stored WD.15 Vacuum and pressure equipment are provided with appropriate control devices, relief valves, guards, barriers, etc WD.16 Vacuum and pressure equipment are regularly inspected and tested and the results documented, as per Australian Standard requirements WE Non powered hand tools WE.1 Correct hand tools are provided for the tasks that are performed in the workplace WE.2 Hand tools are in good condition, and free from defects WE.3 Hand tools are stored appropriately when not in use (especially those with sharp edges) WF. Personal protective equipment (PPE) WF.1 Appropriate PPE is readily available WF.2 PPE is well maintained and hygienic WF.3 Gloves are worn if appropriate for the particular task or tool WF.4 Hearing protection is worn according to task, tool and workplace conditions WF.5 Eye protection is provided and is used, especially for impact tasks, e.g. using a hammer on a cold chisel WF.6 Operators of machinery wear clothing that provides full coverage of the body, including arms and legs, as necessary WF.7 Long hair is restrained to avoid entanglement in rotating equipment ANU WHS Workplace Inspection – Workshops Work Environment Group HR Division Version 5: 1/2014 Page 2 of 7 WF.8 WG. Appropriate PPE is also available for visitors Welding WG.1 Hot Work Permits are issued if required in accordance with the ANU Hot Work Permit Procedure WG.2 Hoses and welding leads are in good condition WG.3 Routine welding work is carried out in a well-maintained welding booth WG.4 Screens are provided for any welding outside a welding booth WG.5 Ventilation is sufficient to remove welding fumes WG.6 Personal protective equipment required from welding includes: Face shields with filter lens for electric welding are clean, in good condition and stored correctly when not in use Leather gloves or fire resistant gauntlets, eg Kevlar, are worn for hand and arm protection Overalls, aprons, welding jackets are used for body protection Safety shoes/boots, spats are worn for foot protection Hard hats are worn if working in a construction zone or if others are working overhead WG.7 Combustible or flammable materials are kept a safe distance from heating appliances and all forms of hot work, e.g. gas cutting, grinding, welding, open flame WG.8 A fire blanket is available WH. Electrical equipment WH.1 There are sufficient power outlets (GPOs) for the equipment, machinery and power tools WH.2 All switches, plugs and GPOs are in good condition WH.3 Fittings are protected against external damage WH.4 Double adaptors and piggy-back plugs are not in use WH.5 Extension leads are only used for temporary, short-term power connections WH.6 Power boards with overload protection are used if sufficient GPOs are not available WH.7 Electrical equipment, machinery and power tools, including cords and leads, are in good condition WH.8 Portable power tools are regularly inspected, tested and in good condition WH.9 Electrical equipment, machinery and power tools are earthed or double insulated. Look for the double insulation symbol on the specification plate WH.10 Residual current devices are provided and used when operating portable power tools and equipment WH.11 Where earth leakage protection (RCD) is supplied, it is tested regularly WH.12 Electrical equipment is tested at appropriate intervals, tagged and documented ANU WHS Workplace Inspection – Workshops Work Environment Group HR Division Version 5: 1/2014 Page 3 of 7 WH.13 Any modified/designed (in-house) electrical equipment has been risk assessed and certified as per the University Electrical Safety Management Procedure, e.g. has an ANU certification number WH.14 Equipment is kept clean and dry WH.15 ‘Out of Service’ tags for faulty electrical equipment are available and used WH.16 Suspended pendant power outlets (GPOs) - inspect chain/wire (where possible) ensuring adequate fixing above. Check electrical cable is strain free and tied to the chain, and that the outlet’s housing is hooked on to the chain. WH.17 Heat guns (if present) must be inspected for damage. The heat gun must have an appropriate resting location to enable it to cool safely. (also see Hazard Alert 2012 for more details) WH.18 Uninterruptable Power Supply (if present) has been inspected, tested and maintained according to manufacturer’s recommendations. Some UPS may be monitored. Any UPS in storage must have the battery pack disconnected. (Hazard Alert 2012) WH.19 Uninterruptable Power Supplies (UPS) is appropriately rated, installed and does not pose an unacceptable risk of electrocution. WI. Chemicals (general) Chemical management WI.1 A register of chemicals is available WI.2 SDS are available for chemicals WI.3 Documented risk assessments are available for chemical use WI.4 Carriers are provided for large containers (>2 L) Labelling of chemicals WI.5 Chemicals in use or storage are labelled clearly and unambiguously WI.6 All reused containers have the original label removed or completely covered WI.7 Decanted chemicals are labelled Chemical storage WI.8 Chemicals not in use are placed in correct storage location Note. The ANU Chemical Safety Course and related notes provide information on storage and segregation of chemicals and dangerous goods WI.9 Chemical stocks are kept to a minimum WI.10 Incompatible classes of chemicals are segregated WI.11 Chemical containers are of the correct type and in good condition WI.12 No food containers are in use for the storage of chemicals Storage on open shelving WI.13 All containers are < 5 kg or L in size WI.14 On shelves > 1.5 m high all glass containers are < 1 kg or 1 L WI.15 The shelving is chemically resistant to the chemicals stored Storage in fire-proof cabinets WI.16 All containers in cabinets are <25 L in size ANU WHS Workplace Inspection – Workshops Work Environment Group HR Division Version 5: 1/2014 Page 4 of 7 WI.17 The self-closing mechanisms of the doors are operating correctly WI.18 Incompatible chemicals stored in the same cupboard have separate spill containment Storage in ventilated cupboards WI.19 All containers in cupboards are < 2 kg or L in size WI.20 Incompatible chemicals stored in the same cupboard have separate spill containment WI.21 Ventilation is sufficient to prevent build-up of offensive odours WJ Compressed and fuel gases WJ.1 All the cylinders inside workshops are connected for use WJ.2 Gas cylinders are each securely chained with individual chains secured around the body of the cylinder and the chain ends attached to separate securing points WJ.3 Gas cylinders are at least 3 m away from ignition sources, where possible WJ.4 Cylinders, pipes & valves are protected from mechanical damage WJ.5 Strength of hoses & clamps attached to gas cylinder regulators are sufficient for maximum regulator delivery pressure WJ.6 Obsolete gas regulators are not in use (Hazard Alert 2000) WJ.7 The gas cylinder and major joints are regularly inspected, tested for leaks and any deficiencies documented and corrected WJ.8 Flashback arresters are used in fuel gas supply lines WJ.9 Non-return (check) valves are fitted to all processes that exceed cylinder pressure WJ.10 There is a cylinder trolley (with restraining strap) available for moving cylinders WJ.11 Compressed air used for breathing systems is of breathable quality WJ.12 Unusual gas systems have been inspected and approved by WHS Branch WJ.14 Source of ignition are eliminated from gas cylinder storage areas WJ.15 External storage areas are clean – leaf litter and other combustible material removed WJ.16 Empty gas cylinders are labelled as empty WK Waste management WK.1 All waste is disposed of in an appropriate and environmentally responsible manner WK.2 Wastes are segregated according to hazard, treatment requirements and to optimise recycling opportunities WK.3 Hazardous waste is clearly labelled with waste description and symbols if required and date produced. The waste label includes the waste generator contact details (name, department/school/unit and contact number) and if the waste has had any on-site treatment or testing WK.4 Wastes are stored in ‘fit for purpose’ containers that are able to withstand storage conditions and transport ANU WHS Workplace Inspection – Workshops Work Environment Group HR Division Version 5: 1/2014 Page 5 of 7 WK.5 Hazardous wastes are contained within bunded areas that do not drain to storm water or sewer WK.6 Wastes are stored at appropriate temperatures WK.7 There are sufficient and appropriate waste disposal containers WK.8 Wastes are disposed of regularly and volumes are kept to a minimum WK.9 Materials subject to spontaneous combustion such as oily rags & paint rags are placed in approved oily waste cans that are emptied daily WL WL.1 Environmental issues Chemical containers are cleaned prior to recycling or disposal: Triple rinsed and labels and lids removed before placing in the recycling bins Containers with oily or persistent residues are washed with detergent and labels removed before placing in the recycling bin or industrial hopper WL.2 There is no evidence of incorrect disposal down sinks or into drains, i.e. discoloration, staining, odorous sinks, etc WL.3 There are no odours, dust or smoke in the area WL.4 Swarf and other metal off cuts, oils and solvents are collected for recycling. The collected materials are stored in suitable and clearly labelled containers. Wastes and materials for recycling are regularly collected WM. First Aid WM.1 A first aid kit is available, including a bio spill kit and contamination disposal WM.2 Lists of trained first aid people and contact numbers are displayed WM.3 Lists of first aid people are current WM.4 Notices indicating location of each kit are on display WM.5 Location of the nearest Automatic External Defibrillator (AED) is clearly indicated WM.6 Cabinets and contents are clean, orderly and properly stocked WM.7 First aid resources are appropriate for the hazards and risks that have been identified in the area by a risk assessment WN. Manual Handling WN.1 Unusual manual handling work tasks have been evaluated safe work methods are available. Consider issues like optimising the work station layout, avoiding excessive repetition or work demands, ease of access and movement, taking regular rest breaks etc. WN.2 Material and equipment that needs to be moved can be done so using available equipment and/or suitable techniques WN.3 Mechanical aids such as trolleys, jacks, hoists, adjustable trolleys etc are available and in good working order WN.4 Staff have been trained in safe manual handling techniques ANU WHS Workplace Inspection – Workshops Work Environment Group HR Division Version 5: 1/2014 Page 6 of 7 WN.5 Staff have been trained in the use of mechanical aids ANU WHS Workplace Inspection – Workshops Work Environment Group HR Division Version 5: 1/2014 Page 7 of 7