Laboratories

advertisement

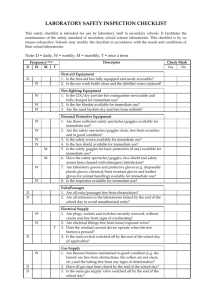

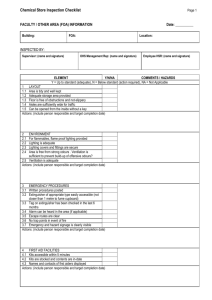

ANU Workplace Inspection Program Inspection Reference Sheet – Laboratories L.A. Laboratory Facilities L.A.1 Access to the laboratory is restricted to appropriate personnel L.A.2 Appropriate PPE is available and in use (minimum PPE includes safety glasses, laboratory coat or gown and closed toe shoes) L.A.3 A variety of appropriate protective gloves are available L.A.4 Safe operating procedures are displayed next to equipment L.A.5 Warning signs for radiation, biological or other hazards are prominently posted L.A.6 Food and drink are not stored or consumed in laboratories L.A.7 Protocols or safe work method statements are available, or risk assessments are conducted of laboratory processes and experiments. The system for generating these documents is known to people. Example documents are available. L.A.8 Key safety documents (eg protocols, assessments, contact lists etc) have version number, date and author details (document control). L.B. Housekeeping L.B.1 Benches are occupied only by chemicals/equipment ‘in use’ L.B.2 Storage of items on floors is kept to a minimum L.B.3 Storage of heavy items above shoulder height is avoided L.B.4 Aisles/exits are clear L.B.5 Spill kits, supplies and decontamination material are available for the hazards present L.B.6 Spill procedures are clearly displayed L.B.7 (Official) Signs are attached to unattended experiments with appropriate details ANU WHS Workplace Inspection Work Environment Group HR Division Version 5:1/2014 Page 1 of 8 L.C. Waste Management L.C.1 All waste is disposed of appropriately L.C.2 Hazardous wastes and materials are contained and do not drain to storm water or sewer L.C.3 Hazardous waste is clearly labelled with waste description, biohazard symbols if required and date produced. The waste label includes the waste generator contact details (name, department/school/unit and contact number) and if the waste has had any on-site treatment or testing. A storage stable risk assessment has been completed L.C.4 Wastes are segregated according to hazard, treatment requirements and to optimise recycling opportunities L.C.5 Wastes are stored in ‘fit for purpose’ containers that are able to withstand storage conditions and transport L.C.6 Wastes are stored at appropriate temperatures L.C.7 There are sufficient and appropriate waste disposal containers L.C.8 Wastes are disposed of regularly and volumes are kept to a minimum ANU WHS Workplace Inspection Work Environment Group HR Division Version 5:1/2014 Page 2 of 8 L.D. Electrical equipment L.D.1 Laboratory equipment, including cords and leads, are in good working order L.D.2 There are sufficient general-purpose outlets (GPOs) for the equipment L.D.3 Double adaptors & piggy-back plugs are not in use L.D.4 Extension leads are only used for temporary, short-term power connections L.D.5 Power boards with overload protection are used if sufficient GPOs are not available L.D.6 Fittings are protected against external damage L.D.7 Equipment and appliances are earthed or double insulated. Look for the double insulation symbol on the specification plate. L.D.8 Equipment that may be left on unattended has a manually resetting over-temperature cut-off switch fitted L.D.9 Electrical equipment is tested at appropriate intervals L.D.10 Any modified/designed (in-house) electrical equipment has been risk assessed and certified as per the University Electrical Safety Management Procedure. (e.g. has an ANU certification number) L.D.11 Earth leakage protection (RCD) is available in wet areas (Electrical Safety Procedure). L.D.12 Where earth leakage protection (RCD) is supplied it is regularly tested L.D.13 Battery recharges are smart chargers (i.e. turn off when charging is complete) (Hazard Alert 2008) L.D.14 ‘Out of Service’ tags for faulty electrical equipment are available and used L.D.15 Suspended pendant power outlets (GPOs) – inspect chain/wire (where possible) ensuring adequate fixing above. Check electrical cable is strain free and tied to the chain, and that the outlet’s housing is hooked on the chain. L.D.16 Heat guns (if present) must be inspected for damage. The heat gun must have an appropriate resting location to enable it to cool safely. Also see Hazard alert 2012 for more details. L.D.17 Uninterruptable Power Supply (if present) has been inspected, tested and maintained according to manufacturer’s recommendations. Some UPSs may be monitored. (Hazard Alert 2012) L.D.18 Uninterruptable Power Supplies (UPS) is appropriately rated, installed and does not pose an unacceptable risk of electrocution. Special equipment L.E. Refrigerators/freezers/cool rooms L.E.1 Flammable liquids are only stored in fridges/freezers that are intrinsically safe L.E.2 Refrigerators, freezers, cool rooms are appropriately labelled (e.g. intrinsically safe) L.E.3 Freezer and cool rooms have well-maintained emergency door releases L.E.4 Fridges, freezers etc. are regularly defrosted ANU WHS Workplace Inspection Work Environment Group HR Division Version 5:1/2014 Page 3 of 8 L.F. Fume cupboards L.F.1 Fume cupboards are appropriate for the type of hazards (ie chemical, biological, etc) L.F.2 The fume cupboard is used with the sash at or below the recommended height L.F.3 The leading edge of the fume cupboard is clear of equipment and other items (also see the Guidelines on the use of Fume cupboards) L.F.4 The area behind the main work area is clear L.F.5 The fume cupboard is free of clutter and large equipment L.F.6 The doors and windows within 1 m of the cupboard are closed when the cupboard is used L.F.7 Emergency switches are clearly identified for power and gas supply L.F.8 The fume cupboard has been inspected and certified within the last 6-12 months L.G Biosafety Cabinets L.G.1 The biosafety cabinet is clean and free of clutter (i.e. routine cleaning performed recently) L.G.2 The biosafety cabinet has been inspected and certified within the last 12 months L.H. Centrifuges L.H.1 The rotor is regularly inspected and the results documented in a log book L.H.2 The rotor speed has been recently calibrated (Hazard Alert 2007) L.I. Autoclaves L.I.1 The autoclave is regularly inspected and calibrated L.I.2 Autoclave records are retained and show that sterilization was achieved L.J. Safety Equipment L.J.1 Safety showers and eye wash facilities are tested at least monthly L.J.2 The eyewash station provides aerated water at an appropriate pressure L.J.3 Safety shower and eyewash can be easily accessed (i.e. not obstructed) L.K. Chemicals (general) Chemical management L.K.1 Chemicals are registered on the ANU Chemical Inventory System L.K.2 SDS are available for chemicals (e.g. Chemwatch via ANU web) L.K.3 Documented risk assessments are available for chemical use L.K.4 Carriers are provided for large containers (>2 L, eg Winchester bottles) L.K.5 Unattended reactions have clear signage (especially contact details) L.K.6 Hydrofluoric acid use is careful managed in accordance with ANU Guidelines Labelling of chemicals L.K.7 All chemicals are labelled clearly and unambiguously in accordance with Australian standards and/or University requirements https://policies.anu.edu.au/ppl/document/ANUP_001149 L.K.8 All reused containers have the old label removed or completely covered L.K.9 Decanted chemicals are appropriately labelled ANU WHS Workplace Inspection Work Environment Group HR Division Version 5:1/2014 Page 4 of 8 Chemical storage L.K.10 Scheduled poisons and drugs (S4, S7, S8, S9) are stored in a locked cabinet/safe L.K.11 Users of Scheduled poisons and drugs (S8, S9) have ACT Health approval L.K.12 Scheduled carcinogens are securely stored L.K.13 Users of Scheduled Carcinogens have Comcare authorisation L.K.14 Chemicals not in use are placed in the correct storage location L.K.15 Chemical stocks are kept to a minimum. A standard laboratory is generally allowed 6-8 winchesters each of solvents and acids L.K.14 Incompatible classes of chemicals are segregated (generally by dangerous goods class) L.K.17 Chemical containers are of the correct type and in good condition L.K.18 No food containers are used for the storage of chemicals L.K.19 Unsealed containers of flammable waste are stored in fume cupboards or ventilated cupboards L.K.20 Incompatible chemicals stored in the same cupboard have separate spill containment (e.g. acids and bases) L.K.21 Chemicals of security concern are entered in the Chemical Inventory System (CIS) L.K.22 Chemicals of security concern are stored in locked cupboards or rooms such that unauthorised access is prevented. Chemicals need to be locked away afterhours and when not in use. L.K.23 Chemicals of security concern - Processes are in place that identify any unauthorised use or loss L.K.24 Chemicals of security concern - any identified loss can be reported quickly L.K.25 Users of chemicals of security concern have attended appropriate training Storage on open shelving L.K.26 All containers are < 5 kg or 5 L in size L.K.27 On shelves > 1.5 m high all glass containers are < 1 kg or 1 L L.K.28 The shelving is chemically resistant to the chemicals stored L.K.29 Plastic chemical containers are in good condition and not older than 5 years (or recommended by the manufacturer as a suitable life of the plastic. see date stamp on container) L.K.30 Bottles with liquid dispensers fitted are restrained from falling and accidental discharge Storage in fire-proof cabinets L.K.31 All containers in cabinets are <25 L in size L.K.32 The self-closing mechanisms of the doors are operating correctly Storage in ventilated cupboards L.K.33 All containers in cupboards are < 2 kg or 2.5 L in size L.K.34 Incompatible chemicals stored in the same cupboard have separate spill containment L.K.35 Ventilation is sufficient to prevent build-up of offensive odours ANU WHS Workplace Inspection Work Environment Group HR Division Version 5:1/2014 Page 5 of 8 L.L. Compressed & fuel gases L.L.1 Gases cylinders for permanent installations are stored external to the building L.L.2 Flammable and Toxic gases are stored outside the building and separated by the appropriate distances L.L.3 All the cylinders inside rooms are connected for use (i.e. no laboratory storage) – flammable or toxic gas cylinders may only be used in the fume cupboard, special gas cabinet or with the permission of WHS Branch. L.L.4 (Fuel) Gas torches are less than 1.5kg (Hazard Alert 2003). L.L.5 Gas cylinders are each securely chained with individual chains secured around the body of the cylinder and the chain ends attached to 2 separate anchoring points L.L.6 Cylinders, pipes & valves are protected from mechanical damage/impact L.L.7 Hoses & clamps attached to gas cylinder regulators are of sufficient strength for maximum regulator delivery pressure and made of compatible materials L.L.8 Obsolete gas regulators are not in use (Hazard Alert 2000) L.L.9 The gas cylinder and major joints are regularly tested for leaks L.L.10 Flashback arresters are used in fuel gas supply lines L.L.11 Non-return (check) valves are fitted to all processes that exceed cylinder pressure L.L.12 Unusual gas systems have been inspected and approved by WHS Branch L.L.13 There is a cylinder trolley (fitted with a restraining strap) available for moving cylinders L.L.14 Source of ignition are eliminated from gas cylinder storage areas L.L.15 External storage areas are clean – leaf litter and other combustible material removed L.L.16 Empty gas cylinders are labelled as empty or stored in an area especially for empty cylinders L.M. Cryogenic liquids L.M.1 Cryogenic liquids are located in well-ventilated areas L.M.2 Containers used for cryogenic liquids are designed specifically for that purpose L.M.3 Appropriate protective gloves and face shield are available L.N. Biological hazards L.N.1 Documented risk assessments for use of biological hazards are available L.N.2 Laboratory doors are closed when work is in progress L.N.3 Hand washing facilities are available L.N.4 Biological materials are clearly labelled, dated and appropriately stored L.N.5 Appropriate disinfectants are available L.N.6 Appropriate waste handling procedures are in place (autoclaving, disinfecting etc.) L.N.7 Biohazardous waste and sharps bins are provided, where necessary L.N.8 The sharps containers are of single shell construction or compliant with AS4031 (Hazard Alert 2004) L.N.9 Separate facilities are provided for animal storage, cleaning, examination, etc L.N.10 No items are stored on the floors L.N.11 Immunisations have been considered by staff and students ANU WHS Workplace Inspection Work Environment Group HR Division Version 5:1/2014 Page 6 of 8 L.N.12 Health Surveillance has been discussed with staff and students L.N.13 Glass pipettes have been considered for replacement with alternatives (e.g. plastic) L.N.14 Strong sealable containers are available to transport materials around the building or between buildings L.O. Ionising radiation hazards L.O.1 A radiation safety officer has been appointed to review the radiation work and their details are displayed L.O.2 An appropriate radiation warning sign is displayed at the lab entrance L.O.3 Documented risk assessments and safe work procedures for use of ionising radiation are available L.O.4 Emergency procedures are available and reviewed annually L.O.5 Personnel occupationally exposed to ionising radiation are issued with a personal dosimetry device (e.g. TLD Badge) L.O.6 Radiation contamination monitoring or x-ray leakage tests are regularly conducted and recorded L.P. Radiation hazards - Unsealed sources L.P.1 Documented risk assessments and safe work procedures for use of ionising radiation are available L.P.2 Work surfaces are impervious (wooden benches and tiled surfaces are unsuitable) L.P.3 Hand washing facilities are available L.P.4 Appropriate shielding material is available L.P.5 Secondary containment is available and utilised (i.e. spill trays) L.P.6 All sources of ionising radiation are labelled and stored in secure locations L.P.7 All storage locations of ionising radiation are labelled L.P.8 Appropriate monitoring equipment is available and has been regularly inspected/tested/calibrated. ANU efficiency testing labels should be attached to the equipment. L.P.9 Decontamination/emergency procedures are clearly displayed L.P.10 Contamination checks are conducted before and after each procedure L.Q. Radiation hazards - Sealed sources L.Q.1 Documented risk assessments and safe work procedures for use of ionising radiation are available L.Q.2 Hand washing facilities are available L.Q.3 Appropriate shielding material is available L.Q.4 All sources of ionising radiation are labelled and stored in secure locations L.Q.5 All storage locations of ionising radiation are labelled L.Q.6 Appropriate monitoring equipment is available L.Q.7 Sealed radiation sources are maintained in good order and leak tested ANU WHS Workplace Inspection Work Environment Group HR Division Version 5:1/2014 Page 7 of 8 L.R. Radiation hazards - X-ray apparatus or sealed source apparatus L.R.1 Documented risk assessments and safe operating procedures for use of ionising radiation are available L.R.2 Appropriate shielding material is available L.R.3 Appropriate monitoring equipment is available L.R.4 Appropriate fail-safe devices to prevent accidental exposure are in place L.R.5 Appropriate labelling is in place L.S. Ultraviolet radiation L.S.1 Appropriate shielding &/or interlocks are in place (e.g. interlocks on germicidal lamps, and protective shields on transilluminators) L.S.2 Additional PPE is available (i.e. additional skin and eye protection is available/required for open sources) L.T. Lasers L.T.1 Laser laboratories housing class 3 and/or class 4 lasers are restricted and access is controlled L.T.2 A laser warning sign is clearly displayed at the entrance. This is a black symbol on a yellow background. The laser class and wavelength are also indicated. L.T.3 A laser safety officer is responsible for the area and their name and contact details are displayed L.T.4 Beam is restricted to the optics bench or equipment by a physical barrier L.T.5 Beam stops are installed L.T.6 Appropriate fail-safe devices to prevent accidental exposure are in place L.T.7 Documented risk assessments and safe work procedures for use of lasers are available L.T.8 Procedures (incl. emergency) are reviewed annually L.T.9 Wavelength-specific eye protection is available for laser operators L.T.10 Class 3B and 4 lasers are included on the ANU ARPANSA source inventory as indicated by an ANU ARPANSA apparatus label L.U. Environmental issues L.U.1 Chemical waste bottles are clearly labelled and assessed for storage stability L.U.2 Chemical containers are cleaned prior to recycling or disposal: Triple rinsed and labels and lids removed before placing in the bottle in recycling bins; Containers with oily or persistent residues are washed with detergent and labels removed before placing in the bottle/container recycling bins L.U.3 Contaminated glassware that is not cleaned as above is treated as a prescribed industrial waste L.U.4 There is no evidence of incorrect disposal down sinks, ie discoloration, staining, odorous sinks, etc L.U.5 Hoses in sinks are short to prevent backflow contamination of the water supply L.U.6 There are no odours, dust or smoke in the area L.U.7 All service areas, where chemicals are used and dispensed or where wastes are stored are suitably bunded/protected from leakage into storm water or sewer drains ANU WHS Workplace Inspection Work Environment Group HR Division Version 5:1/2014 Page 8 of 8