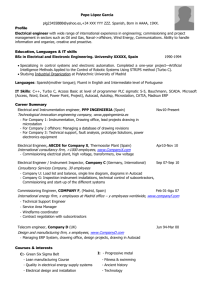

Robert L. Smith CQCM

advertisement

Robert L. Smith CQCM 5107 Crown Cypress Las Vegas, Nevada 89149 702-421-5132 +974 3352 9037 (Doha, Qatar) +974 3351 2758 (Doha, Qatar) bob_smith_54@yahoo.com SENIOR ENGINEER WITH 35+ YEARS OF EXPERIENCE PROFESSIONAL OVERVIEW A highly skilled, dynamic, and solutions-oriented quality control / quality assurance engineering professional. Over thirty years of leadership experience in national and international environments. Hands-on visionary with advanced structural and technical expertise. Excellent qualifications in project management, financial management, client relations, quality control / quality assurance, staff training / teaching, development and communications, Dedicated to the exchange of knowledge between local engineers at various levels of knowledge via proprioritory power point presentations that have been used over the years. The successful completion of many “Mission Critical” projects. A troubleshooter able to effectively and efficiently resolve issues and meet and achieve challenging goals and objectives on time and under budget. Confident in abilities and committed to performance excellence, safety compliance, and cost containment. Team player recognized for propensity to establish and maintain solid relationships with co-workers, customers, management, project principals, vendors, and key internal/external stakeholders. Responsibilities In my role as Construction Quality Control Manager (CQCM) I was to oversee my staff performing all of the major QC activities required per the contract documents, including audit and surveillance activities. To provide in a timely manner the written documentation described in each project's specific contract documents as follows: Create, update and maintain the project submittal log and all other project specific quality control reports that are submitted to the QA Staff. Review/audit shop drawings and submittals for conformance with project specifications by direct review and by leveraging the knowledge and experience of others in the project team when necessary. Chair and document weekly QC meetings with the superintendent and provide written minutes as described in project specific contract documents. (Camp Bastion, Afghanistan) Have weekly meeting with the Afghan Local National QA Engineers to answer any question as to procedures and the future work items. (FOB Thunder and FOB Lightning, Gardez, Afghanistan) Provide written daily QC surveillance reports that reinforce activities that are being constructed in conformance with each specific project's established standard and constructively confronts non-conformances to produce the desired outcome in a timely manner Conduct preparatory, initial and follow-up meetings to establish an understanding of the standards of care desired for each definable feature of work. Verify that checklists are being used and signed off prior to the placement of concrete, steel and other similar items of work Audit and document that all materials received for the project are in conformance with the approved submittal, are handled and stored appropriately and are acceptable for use in the project Conduct preconstruction meetings with new and existing subcontractors and the superintendent at least two days prior to the s tart of each new phase of the work to discuss issues that affect quality. Document these meetings in the daily QC report and Preparatory Phase reports Conduct periodic follow-up audits to verify that work is proceeding with the contract documents and the approved submittals. (Desired results come from what is inspected, not what is expected.). Coordinate and document the testing and commissioning of building systems. Document and distribute pre-punch lists for the contractor and develop a final punch to inspect with the local national QA inspectors and representatives of the US government (the end users). Document final inspections, certificates of occupancy and acceptance of the works and various phases thereof. Maintain the project "as-built" drawings on a daily basis Assemble and forward project closeout documents that include O&M manuals, as-builts and warranties Stop work if necessary to resolve matters that affect safety, quality and/or inhibit the logical progress of work CORE COMPETENCIES Project Management Quality Control / Quality Assurance Safety/Regulatory Compliance Knowledge of ISO 9001 Quality Management Systems Client/Customer Relations Employee Supervision Cost Containment Budgeting Vendor Relations Planning & Development Research Analysis/Investigation Dynamic Analysis & Failure Mentoring Local National Quality Assurance (LNQA) Manage Complex Disciplines Competence Under Pressure Diagnose/Troubleshoot Problem Team-Oriented Leadership Optimization Scheduling CERTIFICATIONS ACI Level I AWS Associate Welding Inspector OSHA 30hr ICC Special Inspector for; Structural Masonry, Reinforced Concrete, Structural Steel & Welding, Pre-stress Concrete DOT Certifications Portland Cement Concrete Level I, II Bituminous Concrete Density Tester Course Hot Mix Asphalt Level I Superpave Field Control USACE Quality Control Manager Transportation System Center PCC & HMA Airfield Paving Good working knowledge of EM 385-1-1 (U.S Army Corps of Engineers Safety and Health Requirement Manual) KEY QUALIFICATIONS/HIGHLIGHTS OF PROFESSIONAL EXPERIENCE Design, review, and supervise all contractors submittals and engineering calculations and drawings for vertical structures and various components of concrete structures including beams, columns, foundations, slabs, airfield, apron, roadway, electrical, HVAC (Heating & Air Conditioning) etc. Design build construction and government design construction for vertical construction as well as aviation hangers, and various military structures water supply and the piping of said water as well as the associated sewer system. Implement various components including rigid and semi-rigid frames, expandable frames, beam and post, connections (bolted and welded), crane beam, mezzanine beam, columns, base plate, anchor bolts, purlin, girt, clips, and wind bracing. Review of buildings using various codes including: AISC, MBMA, UBC, IBC, ASCE, IS, NBC etc. Preserve quality of design, detailing and scheduling activity through ongoing audit and surveillance activities of contractors and vendors, taking care to accurately report and satisfy client/employer needs regarding ongoing quality activities. Preserve Maintain current building code information and ISO 9001 records per required guidelines. Mentoring of the LNQA engineers in the requirements of the records. Evaluate buildings/bracing systems under extreme environments including wind, seismic, snow, drift load, etc. Mentoring Consistently meet stringent schedules and internal customer requirements (sales, budget, quality control, etc). Develop, plan, implement, and schedule projects; manage the design and detailing phase of each assignment; overseeing job schedule and production readiness with respect to field activities. Aid the Project Engineer should the development of a recovery schedule be needed and share my experience of how to keep all on task and on schedule. Mentoring the LNQA in the importance of the recovery schedule and the critical parts to watch. Recommendation of redesign for expeditious construction process to increase the construction schedule when necessary. Investigative aptitude to improve methods and processes in the organization; recognize, analyze, diagnose, recommend, and resolve economical solutions to technical problems quickly and precisely; facilitate field modifications, repairs, sketches, site visits. Review contract documents and construction drawings for completeness and proper depiction contract requirements. Consistently maintain high level of customer, contractor, architect satisfaction and governmental agencies; accurately and precisely fulfill requirements, resolve/manage conflicts and issues appropriately; present solutions efficiently and effectively. Oversee and direct junior engineers, mentor the development of Afghan national quality assurance team members to enhance the performance of duties for the US Army Corp of Engineers. CHRONOLOGY OF PROFESSIONAL EXPERIENCE Velosi –leased to Overseas Bechtel International as Quality Control Manager Hamad International Airport, Doha. Qatar Bryan International Construction - Bagram AB Afghanistan Senior Construction Quality Control Manager SOLTEK PACIFIC, An Air Force Base in Nevada Contract Quality Control Manager Environmental Chemical Corporation (International), Afghanistan, (Camp Bastion and Camp Leatherneck) Contract Quality Control Manager June 2013 - Current o BYA International, Inc., Afghanistan, (FOB Thunder) Contract Quality Control Manager April 2010 – November 2010 o Tug Hill Construction, Inc., Fort Bliss Army Base, El Paso TX Contract Quality Control Manager July 2009 - April 2010 o Oakland Construction, Creech AFB, Indian Springs, NV Contract Quality Control Civil/Structural Manager April 2006 - July 2009 o GeoTek, Inc., Las Vegas Nevada Project Manager (Residential and Commercial Projects) August 2005 – April 2006 o ARK Engineering, Minute Made Stadium (Cincinnati, Ohio) PM Representative (Environmental, Geotechnical, Quality Control Civil/Structural) October 2002 – August 2005 o Professional Services Industries, Inc., Stafford, Texas Department Manager (PSI), (Radiation Safety Officer and Safety Manager) PM Representative for the New Astor Dome, Houston Texas July 1999 – September 2002 o Twin City Testing -Huntington Engineering – Maxim Technologies, Waterloo, Iowa Senior Geo-Technical Engineering Manager (Radiation Safety Officer and Safety Manager) October 1991-June 1999 o Geo-Technical Services Inc., Iowa City, Iowa Regional Manager Geotechnical Engineer (Radiation Safety Officer and Safety Manager) August 1988- October 1991 o Robert W. Hunt, Company, Chicago Illinois Regional Manager (Radiation Safety Officer and Safety Manager) PM Representative for Chicago Metropolitan District (Deep Tunnel (TARP ) project June 1977 - August 1988 o o o o June 2012 – June 2013 May 2011 – June 2012 November 2010 – February 2011 EDUCATION Bachelor of Science (Civil Engineering) Illinois Institute of Technology Chicago, Illinois Bachelor of Arts (Communications) Seton Hall University South Orange, New Jersey TECHNICAL ADDENDUM Geo Technical Experience MS EXCEL MS Word EM 385 (USACE Safety Manual) Material Engineering MS Office RMS (USACE QA/QC) QCS (USACE QA/QC) Safety and Radiation Safety Work Flow Review for Efficiency Team Building PROFESSIONAL AFFILIATIONS ASTM (American Society of Testing Material) D-18 committee TRB (Transportation Research Board) Concrete, Asphalt and Emerging Technology Committee PROJECT EXPERIENCE The State Illinois Center designed by Murphy/Helmut Jahn. Opened in 1985. This project takes up the entire square block of Chicago downtown real estate. Airfield pavement both commercial Airports and Military facilities; Chicago O’Hair and Midway, Creech AFB, Nevada, Camp Bastion Helmand, Afghanistan, QC/QA for the civil engineering part, electrical and water distribution system, lighting and grounding system. Airfield fuel tank systems and bladder tanks installed in association with the above. Highway reconstruction as well as new roadway for; Illinois, Interstate 90 (the Kennedy Expressway), Illinois Route 120, Interstate 75 Cincinnati Ohio, Interstate 610 and 10 in Houston Texas. Chicago Deep Tunnel, $192 Million is one most challenging projects that I have been a part of was the construction of a 109 miles (174 kilometers) of tunneling ranging from 9 to 47 feet diameter 300 feet below the surface to create a tunnel network. The mining process will end up being a concrete cast in-place piping system known as “The Deep Tunnel and Reservoir Plan” (abbreviated TARP and more commonly known as the Chicago Deep Tunnel) is a large civil engineering project that aims to reduce flooding in the metropolitan Chicago area, and to reduce the harmful effects of flushing raw sewage into Lake Michigan by diverting storm water and sewage into temporary holding reservoirs. The megaproject is one of the largest civil engineering projects ever undertaken in terms of scope, cost and timeframe. Commissioned in the mid-1970s, the project is managed by the Metropolitan Water Reclamation District of Greater Chicago. Completion of the system is not anticipated until 2019, but substantial portions of the system have already opened and are currently operational. Across 30 years of construction, over $4 billion has been spent on the project. When completed the reservoirs will collect combined stormwater and sewerage collected by the 109 mile long Deep Tunnel. Okland Construction …. $148 Million -- Creech Aid Force Base - I was responsible for all Civil/Structural Quality Assurance and Quality Control management issues (This project consists of the construction of 12 vertical multiple structures including; (1) 40,000 SF Maintenance Hangar, (2) 30,000 SF 2-story Squadron Operations/AMU Facility for MQ-1 and MQ-9 aircraft, this facility was designed to accommodate twelve aircraft; this required clear spans inside the hangar of approximately 142 feet by 250 feet by 27 feet high) the concrete floor to the hanger was a 35,500 sq. ft. super flat with specified FF and FL’s and required careful controls in order to meet the requirements of the project, (3) 14,000 SF Addition to a Ground Control Station, (4) 71,000 SF Warehouse Parts Store & Casket Storage, (5) 24,000 SF Addition to a General Purpose Maintenance Facility, (6) 24,000 SF Fuel Cell Maintenance Hangar, (7) Four 2,400 SF Munitions Storage Igloos, (8) 6,000 SF Munitions Maintenance Facility, (9) 4,500 SF Equipment Maintenance Facility, (10) 16,000 SF Field Training Unit Hangar Addition, (11) 12,000 SF Armament Shop, and (12) 8,000 SF Maintenance Training Addition as well as three airfield apron paved areas the concrete used for this was from 11 to 14 inches thick.) These projects required the CQCM to review, comment, and process submittals to the COE, draft RFPs referencing relevant specification and include appropriate sketches to illustrate proposed work. (oversee grading, compaction test, roadway, water supply, sanitary sewer line installation, electrical distribution, lighting, as well as vertical construction noted above). Participate in the RFP’s cost negation with the owner, project control of all site quality control requirements including RMS/QCS updates, document control, inspections, as-built drawing control, submittals, attendance at owner and subcontractor meetings, meeting minutes and ensuring Quality Control and Safety practices are enforced I provide quality control oversight for geotechnical, concrete, structural steel as well as erection items and more as per request for the contract I also review submittals and direct the services of the testing firm for the project. Engineering Position Experience Velosi/Overseas Bechtel International (Doha International Airport Completion Phase) Senior Quality Control Manager BYA International, Inc., Afghanistan, (FOB Thunder ) $78 Million Contract Quality Control Manager Bryan International Construction (Bagram AB, Afghanistan $36 Million) Senior Quality Control Manager SOLTEK PACIFIC Construction, (An Air Force Base in Nevada $98 Million ) Contract Quality Control Manager Tug Hill Construction, Inc., (Fort Bliss Army Base, El Paso TX $63 Million ) Contract Quality Control Manager Environmental Chemical Corporation (International), Afghanistan, (Camp Bastion and Camp Leatherneck $96 Million) Contract Quality Control Manager Oakland Construction, (Creech AFB, Indian Springs, NV $148 Million ) Contract Quality Control Civil/Structural Manager QC Manager and the QC Electrical Engineer confirm that all the requirements of the Engineer of Record for the design and the construction of Interior and Exterior Lighting Design, Interior Electrical Power Distribution Systems, Exterior Power Distribution to Class 35kV, Large Un-interruptible Power Systems, Large Emergency Power Generation Systems to 750kVA, Electrical Power Quality Analysis Documentation & Harmonic Current Attenuation Design are adhered to during construction. The QC staff maintains a watchful eye over the construction. Create and maintain daily log of the construction operations, shop drawings, respond to RFI (requests for information), prepare weekly construction reports, document the construction with digital photographs, supervise and check laboratory sample testing, assist the superintendent or project manager in the preparation and documentation for field change orders, conduct periodic jobsite meetings, conduct the three phase inspection process as set forth by United States Army Corp of Engineers (USACE), conduct or supervise training O&M personnel, prepare or supervise preparation of O&M documentation, conduct or supervise start-up and commissioning, prepare as-built drawings. PROJECT START-UP & COMMISSIONING: The Government describes commissioning of a project as construction completion; energizing the systems; loading the systems; starting all equipment; certifying that the systems operate within specified contractual requirements; training of the operations personnel to the point that they are understand the equipment and are comfortable operating the equipment; and training of the maintenance personnel to the point that they are able to safely maintain the equipment. The contractor is or may be required by contract to prepare written documentation and conduct training sessions for the start-up, operation, maintenance and commissioning of non-standard systems, cryogenic circulation systems, VOC aeration systems, and other special and complicated systems. MECHANICAL COMMISSIONING: I have overseen and coordinated for our mechanical QC engineer for the equipment start-ups, water balancing, air balancing, and operational testing for the commissioning of the HVAC systems. This includes the certification of the air distribution system balancing, air flows, water circulation system balancing, chiller capacity, boiler capacity, controls, Ut ility Control/Energy Management System function/program/operation, and thermal systems. Where needed worked with the mechanical QC engineer on items that include flow, temperature and pressure measuring devices as required for accurate determination of operating condi tions into the contract drawings. I confirm with the mechanical QC engineer on all portable calibrated instrumentation equipment for field measurement of temperatures, voltages, amperes, temperatures and flows when we are to certify the performance of these systems. All test data measurement acquisition will be performed and certified by the type of individual specified in the contract documents traditionally a Registered Professional Engineers. I along with the mechanical engineer provide the maintenance personnel training with the start-up & commissioning. ELECTRICAL COMMISSIONING: I have overseen and coordinated with our electrical engineers on-site for the resistance certifications, equipment energizing, load start-ups, phase balancing, power factor balancing, and operational testing for the commissioning of the Electrical systems. This includes the certification of the controls, Fire Alarm System, Nurse Call System, Utility Control/Energy Management System function/program/operation, and other systems. I confirm with the electrical engineer on all portable calibrated instrumentation equipment for field measurement of temperatures, voltages, amperes, temperatures and flows when we are to certify the performance of these systems. All test data measurement acquisition will be performed and certified by one of our Registered Professional Engineers. I along with the mechanical engineer provide the maintenance personnel training with the start-up & commissioning. AS-BUILT DRAWINGS: I normally specify that the contractor keep two sets of blue-line prints on the jobsite for as-built record keeping as a part of the QC plan and default to the construction contract requirements if more are asked for. The contract or the contract specifications traditionally requires these blue-lines to be maintained contractually and I follow up with the project manager or program manager to gain their assistance with the superintendent on this very critical item. The blue-lines will mark each hidden feature and/or utility with an exact dimension so that these features may be located for repair and/or addition after the construction is complete. GeoTek, Inc., Las Vegas Nevada, Project Manager, my responsibilities were the management of several projects at a time. I was assigned services on/for public works projects, master planned communities, residential developments, high rise condominiums, office buildings, commercial structures, airports, major universities (UNLV), and State Department of Transportation infrastructure projects. In Nevada there is a greater emphasis on the IBC chapter 17. Thus I was responsible for about 25 projects both commercial and some residential for compliance to the code requirements, as well as issuing various phase reports as well as the preparation of t he final special inspection report (Final QAA report as well as Final Grading Plan reports for the county). ARK Engineering, Inc. Ark was contracted to plan and formulate the re-construction and the “Go Forward” plan for a Las Vegas corporation. Get approval from corporate authority and bring the office into compliance with Clark County inspection requirements in the most expeditious manner. Organize project staff to deal with a special situation the office was involved with. Mitigated potential damages by perform ing forensic investigation to confirm inspectional findings. Assign qualified project personnel to specific phase or aspect of project, structural concrete, reinforcing inspections welding, and QA finals. The development of over 40 work plans for the companies for response to the Clark Counties project review. Coordinates activities concerned with technical developments, scheduling, and test protocols. Evaluate and approve test results as well as field reports for compliance. Another contract, I was to quickly restore the firm to the level it was at prior to the Union picked the firm, and the subsequent union agreement signed by the firm. I managed the re-staff (from 3 to 47) as well as increasing the level of professionalism of the CMT department. I prepare the QA/QC manuals for the lab’s certification, and develop a calibration program for the department. I was responsible for the company to have billings of $3.8 million the following year. I prepared proposals for the 2 largest projects that the local company has ever been awarded. (Pharmaceutical Company expansion and a high-rise in Downtown Chicago) Development of all the manuals and calibration logs for the company to become an American Association for Laboratory Accreditation (A2LA) certified laboratory. Developed and train employees how to maintain logs for governmental review. Professional Services Industries, Inc. Stafford, Texas (Project such as Reliant Stadium) The stadium was constructed at the cost of $352 M I was tasked to run the Stafford CMT profit center. I managed, coordinated, and exercised functional authority for planning, organization, and completion of engineering project within area of assigned responsibility. Assigns project personnel to specific phases or aspects of project, such as structural fill projects, in fields sampling of concrete, soils and asphalt. Reviews plans for compliance with engineering principles, company standards, customer contract requirements, and related specifications. Coordinates activities concerned with technical developments, scheduling, and resolving engineering design and test problems. Evaluates and approves reports, drawings, specifications, and budgets. Project controls (expenditures) within limitations of budget. Prepares interim and completion project reports for corporate. I was responsible for invoice review and approval, Profit and Loss responsibilities. Twin City Testing - Huntington Engineering – Maxim Technologies Waterloo, Iowa My role was to develop, implement and market comprehensive geotechnical engineering services in the Eastern Iowa area. Responsibilities included scheduling of field inspectors and the drill rigs. Troubleshoot field situations and present my observations to the engineer of record so as to provide the best remedial course of action that was in the best interest of the client maintaining structural integrity. Geo-technical Services Inc. Iowa City, Iowa I established an Iowa City office, generating $1,483,700 in first year billings. I administered Ames, Iowa office. I developed model costeffective site investigation format for farm co-operatives that provided chemical analysis of soil and water samples monitoring for VOC’s, fertilizer, pesticides, nitrates, carcinogenic and non-carcinogenic PNA’s. I initiated involvement of company in UST community cleanups Initiated involvement of company in landfill re-permitting. I served as Contract Quality Control Officer (Civil/Structural/Environmental) for projects at Offutt Air Force Base Robert W. Hunt, Chicago, Illinois I oversaw and managed all operations for the Chicago laboratory of this nationally established independent testing agency. Prepared specifications for quality assurance projects for nuclear power plants as well as hospital, roadway construction and the largest project our department had ever been a part; The Metropolitan Sanitary District "Deep Tunnel" projects TARP. I served as Contract Quality Control Officer (Civil/Structural) for 3 years for projects at The Great Lakes Naval Base. worked closely with the pioneers of super flat floor technology (Allen Face) to design and place the first super flat floor (200,000 square feet) in the Chicago metropolitan area. I also prepared annual budgets and generated profit and loss statements. Selected and trained field technicians, supervising a staff of 32. Recruited, trained and supervised a marketing associate; implementing a marketing program specifically for laboratory services. Projects of My Career (partial list) I have had the opportunity of working with some of the finest engineers on some very large and well know regionally 9 Barrack’s and infrastructure for said facilites Bagram AB Afghanistan Mission control Command Center at Creech AFB Fort Bliss Airfield and infrastructure as well as fuel storage facilities USAF supervised by USACE (El Paso, Texas). 14 Structures and 3 aprons (Airfield Paving) airfield and infrastructure as well as vertical construction projects in various locations for USAF supervised by USACE (Creech AFB, Nevada). 3 Large airfield and infrastructure as well as vertical construction projects in various locations for USAF supervised by USACE and USMC supervised by (AFCEE) The Construction of Minute Maid Park (Cincinnati Red’s Ball park) and the environmental review of the old park prior to demolition The Construction of the Astro Dome 3 Large airfield and infrastructure as well as vertical construction projects in various locations for USAF (USACE) and USMC (AFCEE) Many commercial structures in the Chicagoland area as well as High-rise commercial and residential structures. One of the most expensive Condo high-rise buildings as well. The Deep Tunnel Project (QA/QC) (a Metropolitan District Project in Chicago, Illinois) Provident Hospital, Chicago, Illinois St Francis Hospital project Blue Island, Illinois. Nuclear Industry QA/QC work at Comanche Peak Nuclear Power Plant Meadowlands Sports Complex QA/QC, Giant Stadium, New Jersey