File - Green Valley Lapidary Club

advertisement

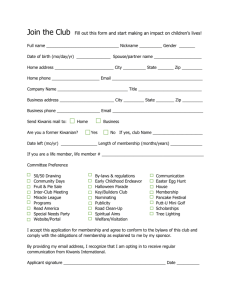

Page 1 GREEN VALLEY LAPIDARY & SILVERSMITH CLUB MEMBERSHIP FORM (Please Print all of your information) Name: Address: City/State: Phone – Home: Email Address: GVR# Zip Code: Cell: In case of emergency, contact: Phone# I give my consent to have my email address printed in the Club’s Roster, which is only available at the front desk of each of the Club’s centers: ______Yes ______ No I am a: ___________ New Member ___________ Returning Member ________________ Part Time GVR Resident ________________ Full Time GVR Resident We are a club of volunteers and the privilege of using our space, equipment, & instruction comes with the trade-off of 12 hours in sharing your time & talents. Below and on the back are opportunities for you to check and see where you would like to contribute. Thanks for helping our club continue to grow. My past experiences afford me to have special abilities/skills that I think might be helpful to the club, such as: ____________________________________________________________________________________________________________ ________________________________________________________________________________________________________________________ Monitor…Please check this form for completeness and legibility. Monitor Initials:____________ Give a copy of the Shop Rules to new member, have them read it, and then have them sign below. DUES: $40 per year Paid by: Check___________ Cash_____________ Credit Card______________________ Monitor initial:_______________ With my signature I acknowledge the receipt of the Shop Rules. I also acknowledge that I am required to give a minimum of 12 hours of volunteer time each year to the Club. I further agree to pay the Club 10% commission on all jewelry items in which I used the club facilities/equipment to make, if I sell those items via Markets, Festivals and/or online outlets, as stated in the Revenue Policy found in the Membership Book located in each of the three centers. Member Signature ____________________________________________________________ Revised: 2/9/2016 12:51 AM Date___________________________ Board Electronically Approved September 29, 2015 Page 2 GREEN VALLEY LAPIDARY & SILVERSMITH CLUB MEMBERSHIP FORM We appreciate your membership in the Lapidary Club. Our Club is a Volunteer Club and each member is expected to volunteer to keep our club going. Please take a minute to check the area(s) below in which you would be interested in donating your time. If you have questions about the volunteer areas, please check the “Volunteer Information Notebook" that is in all three centers. Areas of Interest Instructor Assistant Admin Teachers General Instructor Aide Aide Organization Casting Chaining Channeling Dichroic Glass Enameling Kumihimo Lapidary Metalsmith Precious Metal Clay Silversmith Viking Knit Wax Carving Wire Wrap Computer/Data Entry These Committees need volunteers for a variety of duties, Committees: Cheerful Chauffeur Display Education Equipment Maintenance Festival Financial Guest Speaker Program Publicity Social mark which committee(s) you might be interested in Website Monitor Indicate with a "P" if you Presently are a monitor and a "L" if you would Like to monitor. Revised: 2/9/2016 12:51 AM East I presently do or would like to monitor at: (indicate which center(s) you prefer) West Desert Hills Board Electronically Approved September 29, 2015 Page 3 GREEN VALLEY LAPIDARY AND SILVERSMITH CLUB SHOP RULES The monitors on duty have the authority to enforce these shop rules. No work may be done in the shop without two monitors on duty. No one under 18 years of age will be allowed to operate equipment. Anyone who works in the shop must be a current GVR member and current Lapidary Club member or class student. Members must sign in at the computer (swipe your card). Users are responsible for any damage to equipment or tools and are required to pay for damage if required by the club board. The club provides safety equipment for eyes, ears, and nose. Members are encouraged to utilize them. - Safety glasses, ear protection, and dust masks are available at each facility. - Refer to Better Safe than Sorry or class handouts for addition safety items. Loose clothing, long hair, etc must be contained so that it cannot be caught in rotating equipment. If you are unfamiliar with a piece of equipment please check with an on duty monitor. The monitors are there to assist you in the safe and proper usage of club equipment. Some club equipment needs User Certification to operate. Notify a monitor if you find equipment inoperable or in disrepair. Use of equipment and tools is at the risk of the user. Be respectful to the Club and its members by cleaning up after yourself. When finished using equipment such as saws, grinders, burnishers, buffing wheels, etc., clean up, please leave your work station clean. Equipment cannot be used for commercial purposes, but must be used for hobby or craft items for gifts or for sale on a limited basis. Members should limit time on equipment if others are waiting to use that piece of equipment. All members are expected to abide by the Revenue Policy as stated on the Membership Form and which can be found in the Membership Book located at each of the Centers. Members shall not approach customers or interfere with the monitor when customers are in the shop unless the monitor requests the member’s help. If a satisfactory piece is not available for the customer from the display case, the monitor may request a member’s assistance in providing an item that will meet the customer’s needs. Violations of these shop rules or continued abuse of equipment will be grounds for suspension or expulsion from the club. Appeal can be made to a special meeting of the club board and their ruling shall be final. VISITORS will maintain a safe distance from and will not touch equipment. Visitors will not be permitted in the findings area. Eye protection is available when observing machines in operation. Children must be supervised by an adult when visiting the shop. Revised: 2/9/2016 12:51 AM Board Electronically Approved September 29, 2015 Page 4 Better Safe than Sorry!!! The following is a safety overview, additional information may be provided during classes. Safety of our members, equipment, and facilities is of prime importance. We want a safe environment to learn and practice our hobby. Our Board of Directors, Facility Managers, Monitors, and Instructors have taken measures to provide safe operating environments but each member must also work to maintain and ensure safety of themselves and other members. These volunteer members are not the police so respect their assistance. CLOTHING. Wear protective clothing (closed toe shoes and long pants or shop aprons, not sandals or shorts without leg covering); hot metal and heavy objects might fall on unprotected legs and feet. Do not wear loose shirts, flowing sleeves, scarves, or other garments that can catch fire or get caught in rotating devices (saws, grinders, polishers, etc.). Tie long hair back. EYE PROTECTION. Eye protection should be used when operating lapidary saws and grinders, polishing buffers, and flex shafts because they can throw pieces of rock, metal, buffing compound, broken cut off wheels, etc. Each facility has safety glasses/face shields available for use. Most reading glasses provide poor eye protection. Torches and kilns give off infrared rays that can speed cataract development. For extended soldering times, eyes should be shielded with shaded goggles/glasses. For casting metal, melting metal, and oxyacetylene torches, always use shaded goggles/wraparound glasses. RESPIRATORY. Particulate. Polishing compounds contain a variety of materials including microcrystalline silicate minerals. Face masks should be used when sanding or polishing on buffing machines or flex shafts. Any fine powder, including powdered enamels, dry metal clay, investment powder, and kiln residue papers can cause respiratory problems. A dust mask should be worn when using these materials. Many rocks and organics contain harmful compounds and should be worked wet; the residue should be thoroughly flushed down the drain. Fumes and odors. Some soldering fluxes contain compounds which may be harmful to inhale. Melting/burning materials (e.g. epoxy glues) that produce toxic or noxious fumes or odors should be done only where good ventilation is available. Fumes from heated Nickel (German silver) are toxic. Hot metals should be quenched in water before being placed into a pickle pot to reduce acidic vapors. BURNS/FIRE. All torches (butane, acetylene, oxyacetylene, etc) all operate at high temperatures. Extreme caution should be exercised when these torches are lit to avoid burns and fires. Remove flammable materials from the area; know where the torch is pointed. Many materials retain heat and can cause residual burns. NOISE. Lapidary saws and grinders, polishing lathes (buffers), flex shafts, hammering, and hydraulic presses produce loud noises. Exposure to loud sounds can lead to hearing loss, tinnitus, and other problems. Each facility has disposable ear plugs and ear muffs to provide additional hearing protection at the individual level. ACCIDENTS. It takes only a moment for an accident to occur and only a moment to prevent them. Turn off power to motor driven equipments (saws, grinders, polishers, etc) before walking away from them. Avoid slips and falls by cleaning lapidary saw oil dropped on floors; oil and water is a very slick combination. Clean up any broken glass shards or pieces of sharp metals. Oxygen and acetylene tanks are under high pressure; they must be secured vertically. A tank that falls over could explode, turn into a dangerous rocket, or the valve head could be damaged causing the tank to leak. When tanks are changed, check for leaking gas using leak detection solution. Cuts and puncture wounds are possible, so know where the first aid kits are in the facility and verify that your tetanus vaccination is current. OTHER. Don’t operate equipment beyond your personal comfort level. Make Monitors or Facility Managers aware of unsafe conditions. Material Safety Data Sheets (MSDS) are available at each of the facilities. Red equipment maintenance tags indicate that there is a problem with that equipment; the equipment should not be used unless it is verified that a safety issue is not involved. Revised: 2/9/2016 12:51 AM Board Electronically Approved September 29, 2015