Ohta_dissociation of Mw_SI0512

advertisement

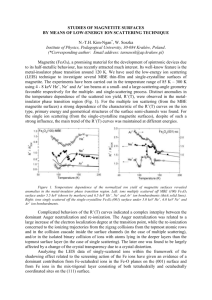

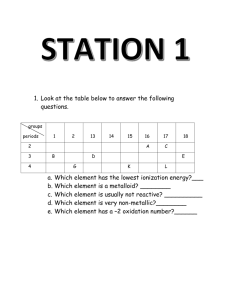

1 Auxiliary Material for “Highly conductive iron-rich (Mg,Fe)O magnesiowüstite 2 and its stability in the Earth's lower mantle” 3 4 K. Ohta,1, 2,* K. Fujino,3 Y. Kuwayama,3 T. Kondo,4 K. Shimizu,1 and Y. Ohishi5 5 6 1 7 University, Osaka, Japan 8 2 9 Tokyo, Japan Center for Quantum Science and Technology under Extreme Conditions, Osaka Now at Department of Earth and Planetary Sciences, Tokyo Institute of Technology, 10 3 Geodynamics Research Center, Ehime University, Matsuyama, Ehime, Japan 11 4 Department of Earth and Space Science, Graduate School of Science, Osaka University, 12 Toyonaka, Osaka, Japan 13 5 14 *Corresponding author: K. Ohta, Department of Earth and Planetary Sciences, Tokyo 15 Institute of Technology, Meguro, Tokyo 152-8551, Japan. (k-ohta@geo.titech.ac.jp) Japan Synchrotron Radiation Research Institute, Sayo, Hyogo, Japan 16 17 18 Introduction 19 This Auxiliary Material contains one text file and one figure (Figure A1). 20 In the text, we show oxidation of magnesiowüstite sample due to ion-thinning for 21 preparation of ATEM observation. Figure A1 shows the X-ray diffraction patterns for 22 magnesiowüstite starting materials we report in the manuscript (2014JB010972). The 23 XRD patterns clearly show oxidation of magnesiowüstite to magnetite after 24 ion-thinning process. Caption of Figure A1 is just below the figure. 25 26 1 27 Online supporting information: Oxidation of magnesiowüstite sample during 28 ion-thinning process 29 30 We found in this study that the SAED patterns of recovered Mw95-1 and Mw95-2 31 samples showed electron diffraction patterns different from the B1 structure (Figure 7). 32 On Mw95-2, all the large (>500 nm) grains (1 in Figure 6c for example) with Mg (pcs) 33 = 0.04–0.06 revealed the superposition of the strong diffraction pattern of the B1 34 structure with a = 4.3 Å and the weak one of the B1-like structure but with the a-axis 35 that is double the normal a-axis (Figure 7c), while the small grain (2 in Figure 6c) with 36 Mg (pcs) = 0.00 only showed a diffraction pattern similar to the B1-like structure with 37 the double a-axis (a = 8.4 Å) (Figure 7d). The SAED patterns from Mw95-1 also 38 exhibit the weak patterns of the B1-like phase. 39 Here we investigated the effect of ion thinning to phase stability in the sample. We 40 performed XRD measurements for (Mg0.20Fe0.80)O and (Mg0.05Fe0.95)O starting 41 materials before and after ion thinning. Ion thinning was performed by Gatan Model 42 691 PIPS (different from the Ion Slicer used in the present experiments). Ion thinning of 43 the pellets of the starting materials was initiated with 5 kV, ~10 A, and the gun angles 44 of 8˚ at the initial stage and finished with 3 kV, ~5 A at the final stage in 5-10 hours. 45 The XRD patterns of all the starting materials before ion-thinning processing showed 46 the B1 structure with a = 4.3 Å, while those of the starting materials after ion-thinning 47 processing converted partially to that of magnetite with a = 8.4 Å (Figure A1). The 48 results clarified that the change of the SAED patterns from the B1 structure sample with 49 a = 4.3 Å to the B1-like structure one with a = 8.4 Å was caused by oxidation of the 50 sample due to the ion-thinning process. The possible reason for the oxidation of 51 iron-rich magnesiowüstite to magnetite is contamination of the very small amount of 52 oxygen in the argon gas, which is irradiated to the samples during ion thinning. The 53 degree of oxidation of the samples by the Ion Slicer seems to be smaller than that by the 54 PIPS. 55 2 56 57 58 Figure A1. XRD patterns for (Mg0.20Fe0.80)O starting material (a) before and (b) after 59 ion-thinning, and for (Mg0.05Fe0.95)O starting material (c) before and (d) after 60 ion-thinning. The calculated peak positions of magnesiowüstite (Mw) and magnetite 61 (Mgt) are shown by small ticks. X-ray wavelength (λ) is 0.71 Å. 3