air seperation plant operator permanent address

advertisement

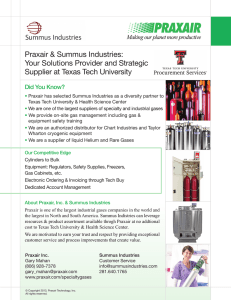

AIR SEPERATION PLANT OPERATOR PERMANENT ADDRESS ZAHID HUSSAIN S/O H. IMAM SAHEB DO.NO.11/1250, 1st Cross J.P.Nagar Bellary Road Hospet-583201 Email: zahid_7@rediffmail.com Zahid_hussain@praxair.com Ph: 08394-265110 M: +91 9341555286. Career Objective To work in a competitive environment with challenging task ahead thereby achieving companies growth and personal growth through continuous improvement in learning and knowledge sharing. Technical Qualification Diploma in Mechanical Engineering T.M.A.E.S Polytechnic College Hospet PRESENT EMPLOYEMENT : Jindal Praxair oxygen company pvt Ltd. Torangallu village,sandur taluk-583123 Designation : Senior Engg operation. Period : from AUG 2010 to Till date. Plant capacity : 2700*2 TPD A Fortune 500 company engaging with industrial gases worldwide ,supplier in india,with more than 35 operating locations,a national distribution network and an impressive list of clients. Praxair also has other active lines of business such as specialty gases,carbon dioxide,health care,surface technologies etc.,. PROFESSIONAL OVERVIEW : Working in a one of the worlds largest oxgen producing plant as a snr engineer, RESPONSIBILITIES : Coordinating with the shift incharge in the shift activities for efecient production of oxygen,nitrogen & argon. Independently able to handle shift operation for Air Separation Plant. Responsible for Production, Quality, dispatch, and plant efficiency. Responsible for ensuring the continuous safe, reliable and efficient operation and maintenance of the plant. Maintains site-specific operating procedures. Provides leadership and oversight of process & process safety management programs Supports compliance with quality systems as well as government regulations. Troubleshooting process disturbances, smooth startup and shutdown for the plants Analyzing the plant parameters for optimization of the process. . Daily plant reports & Trending of process parameters and Tanker Filling Routine Communication with the customers Lead Six sigma projects as a Green Belt for the location. Support Plant manager in meeting savings target. . SAFETY: The assignment Incorporates Job safety analysis, Job safety observation, implementing safety observation system. Conducting process hazard analysis. Preparation of location emergency plan and location environment inventory. Previous Experience NAME OF THE ORGANISATION : MSPL Gases Ltd. Hosahalli. Village Munirabad – 583233, Koppal (Tq & Dt) Designation Period : Assistant manager. : From September 2001 to August 2010. An ISO 9001 company is engaging with industrial gas manufacturing like Oxygen, Nitrogen, Liquid oxygen, Liquid Nitrogen, Dissolved acetylene and also Medical oxygen. It also deals with Argon, Hydrogen, Carbon di oxide and other specialty gases. Company equipped with 200x2m3/hr. Air separation cryogenic plant at filling pressure of 150kg/cm2 to 200kg/cm2 Working Experience and Details As a in Asst manager, operating and setting of 200x2m3/hr. oxygen air separation plant for its higher production rate and minimum specific power consumption with high oxygen purity and overall plant activities. Production planning and control as per dispatch /marketing requirement. Attending both preventive and breakdown maintenance of the plant , which comprises of reciprocating air compressor with inter coolers, heat exchangers, evaporative coolers, molecular sieve driers, alumina filters, chilling unit ,cooling towers, valves like NRV, gate valves, cryogenic valves. Handling of cryogenic liquid safely and efficiently. Maintaining vacuum insulated storage tanks and transport tanks of different capacity vacuum pump and charging pumps. Scheduling of plant maintenance, production planning. PRODUCTIVITY: Implementing various productivity initiatives and cost saving programs. Calculation of saving potential and preparation of feasibility documents for various productivity initiative proposal. HUMAN RESOURCE MANAGEMENT: Planning and managing man power for various in plant activities in shifts and during planned outage. PROJECT WORKED UNDER: Actively participated in Erection and commissioning 200 M3/hr Oxygen plant at Hosahalli and 125 M3/hr. Oxygen plant a t Solapur Maharashtra,600m3/hr plant at bhadravati respectively. Assisted to DGM for implementing power saving project by using heat exchanger during drier regeneration. Improved efficiency of the cooling tower by using evaporation coil inside the cooling tank. HONOURS AND ACCOMPLISHHMENTS: Participated in one month personality development programme by one of the leading training institutes (SHINE) Participated in sap training production planning modules. Successfully completed audit of ISO 9001 which was held by BVQI. PROJECT DETAILS AND RESPONSIBILITIES Study of process line of a plant and set the available space for particular machine. Bedding of machineries as per given drawing. Erection of air compressor, chilling unit evaporative cooler, heat exchanger, high pressure vessels, air separation unit , cooling tower, water pump etc. Pipe line (high pressure and low pressure) work and utility works. PREVIOUS EMPLOYMENT: Name of the Organisation Designation Period : : : Karnataka Oil Federation (Dhara), Hospet. Technician From January, 1998 to May, 2001 Worked in different locations at Edible Oil Packing Station and Oil Mill at Hospet. COMPUTER PROFICIENCY: Operating System Application Software : : Windows 98/2000XP Auto Cad 2000 PERSONAL PROFILE: Father’s Name Gender Date of Birth Nationality Pass Port No. 20/06/2010) Marital Status Languages known Hobbies : : : : : H. Imam Saheb Male 09-08-1977 Indian B- 1907031 (Validity Expiry on : : : Unmarried English, Hindi and Kannada Playing Volley Ball, Cricket, Indoor games & Watching TV DECLARATION I hereby declare that all the information mentioned above is true to the best of my knowledge and belief. Place: Hospet Date: 30.06.2011 Yours sincerely ZAHID HUSSAIN