Descriptions

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Colon University of

Applied Sciences

Tanta University

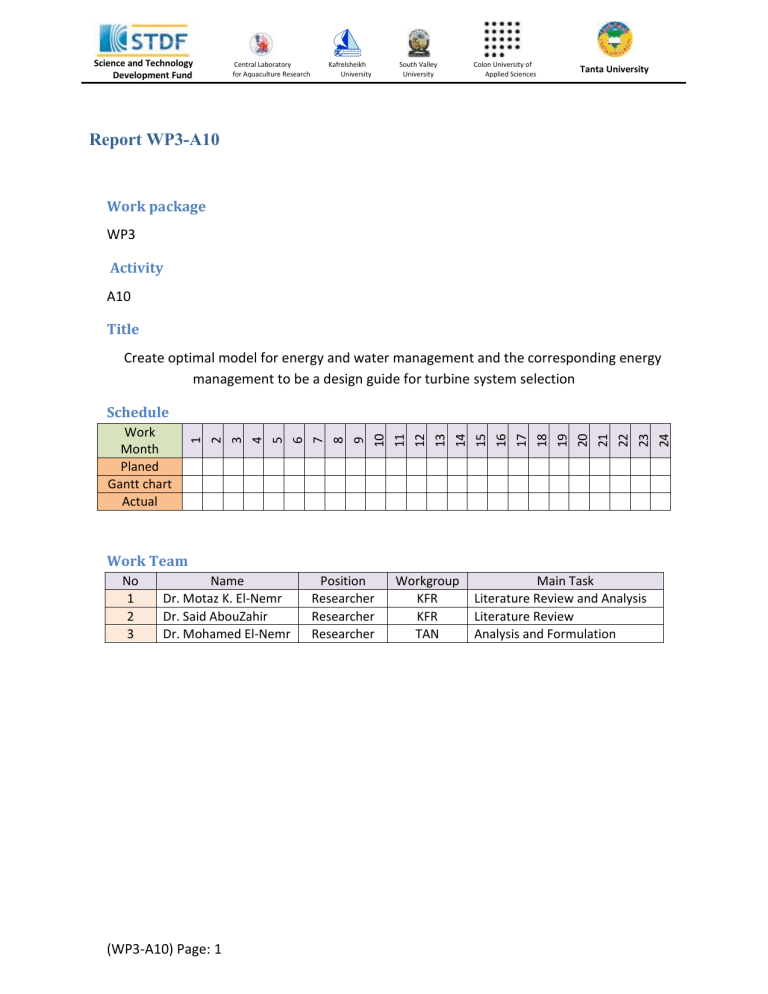

Report WP3-A10

Work package

WP3

Activity

A10

Title

Create optimal model for energy and water management and the corresponding energy management to be a design guide for turbine system selection

Schedule

Work

Month

Planed

Gantt chart

Actual

Work Team

No Name Position

1 Dr. Motaz K. El-Nemr Researcher

2 Dr. Said AbouZahir Researcher

3 Dr. Mohamed El-Nemr Researcher

Workgroup

KFR

KFR

TAN

Main Task

Literature Review and Analysis

Literature Review

Analysis and Formulation

(WP3-A10) Page: 1

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Colon University of

Applied Sciences

Tanta University

Contents

(WP3-A10) Page: 2

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Colon University of

Applied Sciences

Tanta University

(WP3-A10) Page: 3

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Colon University of

Applied Sciences

Tanta University

Table of Figures

(WP3-A10) Page: 4

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Colon University of

Applied Sciences

Tanta University

Objectives

Develop a mathematical optimal model for energy and water management and corresponding energy requirements.

Descriptions

The development of mathematical model for energy and water management will be a key factor to design an experimental system. The rate of aquaculture water change determines the energy requirements. The model relates the total land area, basin area, basin depth, salinity, feeding amount, aerator type, temperature of water and water flow rate. The model determines the suitable aeration rate and water change requirements. The directly leads to the energy requirements to be taken as a guide to select suitable wind system configuration based on each farm conditions.

(WP3-A10) Page: 5

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Colon University of

Applied Sciences

Tanta University

The aim of this activity is to assist the farmer to evaluate the water environment. In addition, scientifically evaluated actions are provided to allow optimal aeration system for fisheries. Easy to use utility is introduced in the form of Microsoft-Excel 2003 Workbook. The workbook has two main work sheets.

First work sheet is the water-environment-judgment sheet. It helps the farmer to know whether the permanent water properties, it is suitability for fish growing. It does judge dissolved oxygen, water temperature, PH, salinity, transparency, and Ammonia. The suitable ranges for each factor affects breeding water were cited from Kaoud 2003. The suitable ranges were for Tilapia, Mullet, and Carp which act the most widely spread fish in Borolus fisheries.

Type

Tilapia

Mullet

Carp

Table 1: Temperature

Range(

C)

8-39

3-35

4-33

Table 2: Oxygen

Type

Tilapia

Mullet

Carp

Optimal Oxygen ( mg/l)

5-10

≥7

≥5 range

4-1

3.7

3

Type

Tilapia

Mullet

Carp

Type

Tilapia

Mullet

Carp

Table 3: PH

Optimal PH

6.7-8.2

7

6.7-8.2

Table 4: Salinity range

5-6.5 and ≥9

<6.5 and ≥ 8.3

<6.5 and ≥9

Maximum Salinity to live

Urea 36-44

Nilotica

Zilli

Fingers

Breeding

11

50

42-45

65

Propagation

6-18

14-29

11-29

≥30

7-9

Optimal

7-9

5-.0.2

5-50

(WP3-A10) Page: 6

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Colon University of

Applied Sciences

Tanta University

Table 5 standard specifications for breeding water

Transparence

Non Ionic Ammonia

NH2

NH3

≥10

0.125 mg/l

0.2 mg/l

3-5 mg/l

Second worksheet helps the farmer to calculate the power requirement for his aeration system for his farm conditions. Consequently, it assists the selection of the most suitable type of aerator according to his budget and farm conditions.

The worksheet will determine the operation time of aerator. Such that, it keeps the dissolved-oxygen content around 8mg/l, which is suitable for the types Tilapia, Mullet, and Carp.

In addition, it avoids the oxygen toxicity. The needed input data and output data are summarized in the next table:

Table 6: Required inputs and outputs

Input

Water temperature, C

Salinity, ppm

Feeding daily amount, kg/d

Water flow rate, m3/s

Basin area, m2

Basin depth, m

Output

Power requirement

Number of units needed

Aeration efficiency

Dissolved oxygen, mg/l

Operating hours

The calculations are arrange in the sequence described in the following few sections. First, the farmer will choose an aeration method to get its standard aeration efficiency. Researchers at Auburn University evaluated the performance of many aerators and studied the effect of design features and operating conditions on performance. Results in terms of pounds of oxygen transferred per kilowatt of electrical power – usually indicated by the Standard Aeration

Efficiency (SAE) - used are summarized in the table below. The average values of SAE were used in calculations.

Table 7: SAE lb O2/hp-hr

Aerator type

Paddle wheel, all types

Propeller-aspirator pump

Vertical pump

Pump sprayer

Diffusion

Average

3.1

2.3

2.0

1.9

1.3

Range

1.6 - 4.3

1.9 - 2.6

1.0 - 2.6

1.3 - 2.8

1.0 - 2.3

Second, the temperature and salinity are used as inputs to calculate the dissolved oxygen and correction factor. The correction factor (cf) values were cited from figure 1.

(WP3-A10) Page: 7

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Colon University of

Applied Sciences

Tanta University

Figure 1: Monograph for estimating correction factors for SOTR and SAE

After that the fixed Oxygen transfer rate per unit time (OTR f

) and field aeration efficiency

(FAE), which is the oxygen transfer per a unit power input under the field conditions, are given for a certain standard Oxygen transfer rate (SOTR), by :

OTR= SOTR* cf (1)

FAE = SAE * cf (2)

Finally the electrical power required can be calculated as follows:

Number of units needed = Supplemental oxygen / (OTRf) (3)

Power requirements (kW) = Supplemental oxygen / (FAE) (4)

The supplemental oxygen can be estimated from the following empirical formals:

Supplemental oxygen=1.44*(OFR)*R-84.4Qw(DOout – DOin) (5) where, DO out

is the effluent DO concentration (mg/L) and assumed to be 8 mg/l , DO in

is the influent DO concentration (mg/L), and Q w

water flow (m 3 /s). The DO indicates the dissolved oxygen.

(WP3-A10) Page: 8

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Colon University of

Applied Sciences

Tanta University

OD max

=1.44 (DODave ) (6) where, OD max

is the maximum daily oxygen demand (kg/d) and DOD ave

is the average daily oxygen demand (kg/d).

DOD ave

= R . OFR (7)

DOD ave

is the average daily oxygen demand (kg/d). OFR is the ratio of average daily oxygen demand to daily feed consumption (kg/kg), and R is daily feed consumption (kg/d). Finally, the dissolved oxygen DO is given by: ln

(DO) = A

1

+ 100 A

2

/ T + A

3

. ln(T / 100) + A

4

T / 100

+ S [B

1

+ B

2

* T /100 + B

3

(T / 100) 2 ] (8) where ln

is the natural logarithm and the other variables take the following values:

Table 8: Table of coefficients

A

1

= -173.4292

B

1

= -0.033096

T : temperature (kelvins)

S :salinity (g/kg)

A

2

= 249.6339

B

2

= 0.014259

A

3

= 143.3483

B

3

= -0.001700

A

4

= -21.8492

Fish use about 150 to 300 mg oxygen per kg of fish per hour for each kilogram of feed applied, 0.2 kg of oxygen will be required (Boyd and Watten 1989). The OFR was assumed 0.2.

The following screen shoots presents the outlines of the developed MS-Excel Workbook. The

Arabic language is used to provide more user friendly interface for farmers in Borolus area.

(WP3-A10) Page: 9

Figure 2: Water environmental parameters

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Colon University of

Applied Sciences

Tanta University

Figure 3: Farm planning

Figure 4: Friendly user interface version with MS-Office 2007

(WP3-A10) Page: 10

Figure 5: User guide with FAQ MS-Office 2007

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Colon University of

Applied Sciences

Tanta University

REFERENCES

Boyd, C. E. 2010. Types of Aeration and Design Considerations . Online document.

Available at" http://aquanic.org/systems/recycle/ces-240_aeration.htm

", June, 25(2010).

Boyd, C. E. and T. Ahmad. 1987 . Evaluation of aerators for channel catfish farming. Ala. Agr.

Exp. Sta., Auburn Univ., Ala., Bulletin 584. 52 pp.

Boyd, C. E. and B. J. Watten. 1989.

Aeration systems in aquaculture. CRC Critical Reviews in

Aquatic Sciences 1:425-472.

Colt, J. 1984 . Computation of dissolved gas concentrations in water as functions of temperature, salinity, and pressure. Amer. Fish. Soc., Spec. Publ. No. 14. 154 pp.

Kowsari,A. 2008. Analysis of design factors influencing the oxygen transfer efficieny of a speece cone hypolimnetic aerator. m.sc thesis. university of british columbia.

Soderberg, R. W. 1982 . Aeration of water supplies for fish culture in flowing water. Prog. Fish-

Cult. 44:89-93.

Stickney, R. R. (2000). Encyclopedia of aquaculture. John Wiley & Sons, Inc.

ةيبرعلا عجارملا

.ةيبرعلا رصم ةيروهمج فراعملا راد .ةبذعلا هايملا تايرشقو كامسأ عرازمو يكمسلا عارزتسلاا .

2003 .ع،ح، دوعاق

(WP3-A10) Page: 11

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Colon University of

Applied Sciences

Tanta University

Program Documentation

The program documented below is a hardware implementation of the calculations of the above described algorithm. The documentations include variable needed

Variables

No. Description Name

1

2

3

4

Total Area

Mother's basins

Incubation basins

Hatchery ponds

5

6

Fattening bonds

Breeding bonds

8 Number of basins

10 Fingers counted

11 Cultural density

12 Water temperature

13 Salinity

14 Feeding daily amount

15 Water flow rate

16 Basin area

17 Basin depth

18 DO

19 Basin volume,

20 Field aeration efficiency

21 Average DOD

22 Maximum DOD

23 Supplemental oxygen

24 Power requirement

25 SOTR,

26 Field OTR

27 Number of units

28 Operating hours per day

29 Salinity

30 Temperature, K

31 SAE

32 Correction factor

33 OFR tArea

MoBasin

IncBasins

Hatchery

Fattening

Breeding

Basins

Fingers

Density

34 Power requirement

35 Number of units needed

Power nUnits

36 Daily operating Time, min OpTimeMin

37 Supplemental oxygen SupOxygen

38 ON/OFF operation

39 Initialization opFlag

InitFlag

Tc

Salinity

Feeding

Qw

Abasin

Dbasin

DO vBasine etaAeration avgDOD maxDOD supO2

Power

SOTR

OTR nUnits

OpTimeH gSalinity

Tk

SAE corFactor

OFR

I/O/M

Default

Value

Unit Type Bytes

Fed

Fed

Fed

Fed

Fed

Fed

Basins

Finger

Fish/m 3

Double 4

Double 4

Double 4

Double 4

Double 4

Double 4

Double 4

Double 4

Double 4

C ppm kg/day m 3 /s m 2 m

Double 4

Double 4

Double 4

Double 4

Double 4

Double 4 mg/l m 3 kW kg/day kg/day kg/day mgO

2

/hr mgO

2

Unit

Hours g/Kg

/hr

Double 4

Double 4

Double 4

Double 4

Double

Double

Double

Double

4

4

4

4

Double 4

Double 4

Double 4

Double 4

Kelvin Double 4 mgO

2

KW/hr Double 4

-- Double 4

Double 4

Hp

Unit

Min kg/day

Double 4

Double 4

Double 4

Double 4

UINT

UINT

2

2

(WP3-A10) Page: 12

Science and Technology

Development Fund

Flow charts

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Init System

Colon University of

Applied Sciences

Tanta University

InitFlag No Init Farm

InitFlag = TRUE

Yes

I, Farm Definition tArea, MoBasin, IncBasins,

Hatchery, Fattening, Breeding,

Basins, Fingers, Density

I, Conditions

Tc, Salinity, Feeding

Qw, Abasin, Dbasin

Calculations

OFR, gSalinity, Tk

DO, vBasine, SAE corFactor, etaAeration, avgDOD maxDOD, supO2, Power

SOTR, OTR, nUnits, OpTimeH

Calculations

Power, nUnits, OpTimeMin, SupOxygen

OpFlag, Timer

No

OpFlag=FALSE

OpFlag

Yes

Timer<OpTime

Figure 6: The program flow chart

(WP3-A10) Page: 13

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Colon University of

Applied Sciences

Tanta University

Functions

Prototype

UINT InitMicro()

Description

Initialize the registers of the microcontroller that includes:

- Ports

- Timers

- Display screen

- Keypad

Parameters

None

Return

True if successful initialization, False otherwise

Prototype

UINT InitVariables()

Description

Initialize the input, output and intermediate variables used in calculations

Parameters

None

Return

True if successful initialization, False otherwise

Prototype

UINT InitDRomVariables()

Description

Initialize the farm variables that should be kept in Dynamic Rom to be available for each restarting

Parameters

None

Return

True if successful initialization, False otherwise

Prototype double TemperatureK2C(double _Tk)

Description

Transfer temperature from Kelvin to Celsius

Parameters

_Tk: temperature in Kelvin

Return

The temperature in Celsius, otherwise ERROR_CALC

Prototype double TemperatureC2K(double _Tc)

Description

Transfer temperature from Celsius to Kelvin

Parameters

_Tc: temperature in Celsius

Return

The temperature in Kelvin otherwise ERROR_CALC

(WP3-A10) Page: 14

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Prototype void SetOFR(double _OFR)

Description

To change the OFR simply

Parameters

_OFR: new value of OFR

Return

None

Prototype double SalinityPPM2g (double _Salinity)

Description

Convert units of Salinity from ppm to grams

Parameters

_Salinity: the Salinity value in PPM

Return

Salinity in grams, otherwise ERROR_CALC

Prototype

BOOL SalinityG2PPM (double _Salinity)

Description

Convert units of Salinity from grams to PPM

Parameters

_Salinity: the Salinity value in grams

Return

Salinity in PPM, otherwise ERROR_CALC

Prototype

BOOL CalcDO()

Description

Calculate the dissolved oxygen using empirical formulas in mg/l

Parameters

None

Return

True if successful, otherwise ERROR_CALC

Prototype

BOOL BasinVolume()

Description

Calculate the basin volume

Parameters

None

Return

True if successful, otherwise ERROR_CALC

Prototype

BOOL FieldAerationEfficiency ()

Description

Calculation of field aeration efficiency

Parameters

None

Return

True if successful, otherwise ERROR_CALC

Colon University of

Applied Sciences

Tanta University

(WP3-A10) Page: 15

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Colon University of

Applied Sciences

Tanta University

Prototype

BOOL CalcSAE()

Description

Calculation of SAE

Parameters

None

Return

True if successful, otherwise ERROR_CALC

Prototype double corFactor()

Description

Correction factor calculated based on curve fitting

Parameters

None

Return

The EROR_COR_FACTOR is set True if calculation succeeds, the return value presents the correct factor.

Prototype void avgDOD()

Description

Calculates the average DOD

Parameters

None

Return

None

Prototype void maxDOD()

Description

Calculates the maximum DOD

Parameters

None

Return

None

Prototype

Void CalcSupO2()

Description

Calculates the supplementary O

2

required

Parameters

None

Return

None

Prototype void CalcPower()

Description

Calculate the required power based on aerator type

Parameters

None

Return

None

(WP3-A10) Page: 16

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

Prototype void CalcSOTR()

Description

Calculates the SOTR

Parameters

None

Return

None

Prototype void CalcPower()

Description

Calculate the required power based on aerator type

Parameters

None

Return

None

Prototype void CalcSOTR()

Description

Calculate SOTR

Parameters

None

Return

None

Prototype void calcOTR()

Description

Calculates OTR

Parameters

None

Return

None

Prototype void CalcUnits()

Description

Calculates the required oxygen units

Parameters

None

Return

None

Prototype void CalcOperationTime()

Description

Calculates the required operation time in hours

Parameters

None

Return

None

South Valley

University

Colon University of

Applied Sciences

Tanta University

(WP3-A10) Page: 17

Science and Technology

Development Fund

Central Laboratory for Aquaculture Research

Kafrelsheikh

University

South Valley

University

Prototype

BOOL GetOperationFlag()

Description

Determine the status of operation

Parameters

None

Return

None

Prototype

Description

Parameters

Return

Prototype

Description

Parameters

Return

Implementation System

Mother Board

I/O peripherals

Screen:

Keypad:

Processor

Code

Colon University of

Applied Sciences

Tanta University

(WP3-A10) Page: 18