June 2014 - Regional Office, Chandigarh

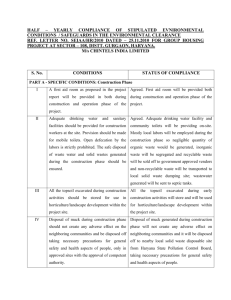

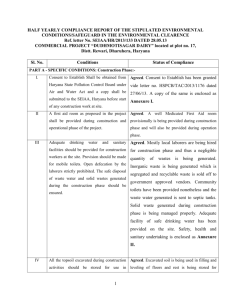

advertisement

Ref: UCC/Sec-71/ MoEF-NRO/2605/2014 To, The Director(S) Northern Regional Office, Ministry of Environment & Forests Bays No.24-25, Sector-31-A Dakshin Marg, Chandigarh -160030 Date: 26.05.2014 The Member Secretary, State Environment Impact Assessment Authority (SEIAA), Haryana Bays No.- 55-58, Prayatan Bhavan, Sector-2 Panchkula-134109 Haryana The Chairman, Haryana State Pollution Control Board, C-11, Sector – 6, Panchkula, Chandigarh-134109 Haryana Ref: EC letter no. SEIAA/HR/2010 45 dated 25.03.2010 Subject: Submission of 9th Six monthly compliance report along with environmental monitoring report (with soft copy in CD) for Commercial (Office cum Retail) Complex “Unitech Commercial Centre” at Sector 71, Vil: Fazilpur, Gurgaon being developed by M/s Unitech Ltd. Dear Sir, This is with reference to point no. ii of the Part B- General conditions of Environmental Clearance (EC) letter no. SEIAA/HR/2010 45 dated 25.03.2010 received from State Environmental Impact Assessment Authority (SEIAA), Haryana. Please find enclosed the 9th six monthly EC Compliance Report along with Environmental Monitoring report (with soft copy in CD) for the above said project Hope, you will find the EC Compliance Report in order and it will help to assess the point wise implementation status of environmental safeguard measures for the above said project. Thanking you, With Regards, For Unitech Limited, Sd/Authorized Signatory Encl: 9th compliance report along with all relevant annexure (with Soft copy in CD). “Unitech Commercial Centre” (SIX MONTHLY COMPLIANCE REPORT) COMPLIANCE STATUS REPORT OF “UNITECH COMMERCIAL CENTRE” COMMERCIAL COMPLEX PROJECT AT SECTOR 71, Vill.: FAZILPUR, GURGAON PART-A SPECIFIC CONDITIONS Construction Phase:i. A first aid room as proposed in the project report will be provided during construction and operation phase of the project. ii. Adequate drinking water and sanitary facilities should be provided for construction workers at site. Provision should be made for mobile toilets. Open defecation by the laboures is strictly prohibited. The safe disposal of waste water and solid waste generated during the construction phase should be ensured. iii. All the top soil excavated during construction activities should be stored for use in horticulture/ landscape development within the project site. Disposal of muck during construction phase should not create any adverse effect on the neighboring communities and be disposed taking the necessary precautions for general safety and health aspects of people. Only in approved sites with the approval of competent authority. Construction spoils including bituminous material and other hazardous materials, must not be allowed to contaminate watercourse and the dump sites for such material must be secured so that they should not leach into the ground water and any hazardous waste generated during construction phase, should be disposed off as per applicable rules and norms iv. v. Yes, Adequate first Aid facilities have been provided for workers during the whole construction phase of the project. Copy of Health Check-up certificate the construction labourers employed at the project site are attached as Annexure I. Yes being complied. Adequate facilities are being provided to the construction labors in regard to drinking water, sanitation and solid waste management. Drinking water for the labour has been arranged by the HUDA water tankers on as and when requirement basis. However, septic tank & soak pit of adequate capacity has been provided for the disposal of waste water at the site. Details are enclosed as Annexure IV. The top soil excavated during construction activities has been stored for use in horticulture/ landscape development within the project site. Being complied. For the disposal of muck during the construction phase As such no hazardous/ bituminous material is being used in construction activity. All possible precautions are being taken to prevent contamination of groundwater/leaching if any. vi. with necessary approval of the Haryana State Pollution Control Board. The diesel generator sets to be used during construction phase should be of low sulphur diesel type and should conform to Environment (Protection) Rules prescribed for air and noise emission standards. During Construction phase for Back-up Purpose D.G. sets (50 KVA & 30 KVA) are used. We have a temporary electricity connection from DHBVN for the project site. D.G. sets are operated only during power failure periodically for construction activities on need basis and are used during daytime only as the construction activities at the project site take place mainly during day time. D.G. sets being used in the construction phase are as per Environment (Protection) Rules for air and Noise emission standard. Only low sulphur diesel is used for DG sets. vii. viii. ix x. xi. Regular six monthly monitoring of Ambient air quality and noise has also been carried out MoEF approved Lab (M/s J.M. Enviro Lab Pvt. Ltd., registration no. T-1327) where directly/ indirectly we are monitoring the D.G. sets with respect to pollution. Ambient air quality and noise monitoring results have been enclosed as Annexure – II for your ready reference. The diesel required for operating DG The diesel required for operating D.G. sets sets shall be stored in underground periodically for construction phase is procured tanks and if required, clearance from on daily basis as per requirement. Chief controller of Explosive shall be taken. Ambient noise levels should conform Available best construction practices are to residential and commercial standards followed to take care of the Environment. The both during day and night. Incremental Environmental Monitoring results are enclosed pollution loads on the ambient air and as an Annexure II for your ready reference. noise quality should be closely monitored during construction phase. Adequate measures should be taken to reduce ambient air and noise level during construction phase, so as to conform to the stipulated standards. Fly ash should be used as building Yes, fly ash based ready mixed concrete material in the construction as per the material is used in building construction. provision of Fly Ash notification of September 1999 and amended as on 27th August 2003. Ready mixed concrete must be used in Yes, ready mixed concrete is used for building building construction. construction. Strom water control and its re-use as Yes, being complied. Storm water control and per CGWA and BIS Standards for its reuse will be as per CGWA standards. xii xiii. xiv xv various applications. Water demand during construction should be reduced by use of Premixed concrete, curing agents and other best practices as referred. Permission from Competent Authority for supply of water shall be obtained prior to operation of the project. Yes, pre-mixed concrete is being and will be used to reduce the water demand during the construction phase of the project. Requisite permission from competent authorities will be taken. Currently the project is in construction phase and we are using STP treated water (after treatment so that it is fit for being used in construction activities and conforms to the Indian standard for Plain and Reinforced Concrete- Code of Practice (Fourth Revision)- IS 456:2000) for carrying out construction activities at the project site. This STP treated water is purchased from HUDA STP as well as we procure STP treated water from our other operational projects through tankers. Please find attached periodic sample copies of the water tanker challans regarding STP water supply to the project site enclosed as Annexure-III. Potable water for construction laborers is being procured from HUDA through water tankers. Periodic sample copies of the water tanker challans are enclosed as Annexure-IV. Roof should meet perspective Roof insulation shall be planned to conserve requirements as per Energy energy. conservation Building Code by using appropriate thermal insulation material to fulfill requirements. Opaque wall should meet prescriptive In the operational phase, appropriate energy requirements as per Energy conservation measures and management plan Conservation Building Code which is will be adopted in order to minimize the proposed to be mandatory for all air consumptions of non-renewable fuel. conditioned spaces while it is aspirational for non-air-conditioned CFL will be used in place of spaces by use appropriate thermal incandescent lamps in office, common insulation material to fulfill areas and parking. requirement. Lighting and switching of common area shall be designed keeping in mind day light integration. Roof insulation shall be planned to conserve energy. D.G. sets would be provided with auto cut and auto start mechanism. The water supply pumping system shall be provided with variable speed drive to conserve energy at part load. Space heating load will be minimized xvi. xvii. xviii i. The approval of the competent authority shall be obtained for structural safety of the building due to earthquake, adequacy of fire fighting equipments, etc. as per National Building Code including protection measures from lighting etc. If any forest land is involved in the proposed site, clearance under Forest Conservation Act shall be taken from the Competent Authority. The project proponent will use the water for construction phase through tankers. However, prior permission from CGWA will be taken before using the bore well water for construction. using passive solar structures. Building will have appropriate design to shut out excess heat and gain loss. The building will be constructed following the NBC guidelines and necessary permission for structural safety as well as fire NOC will be obtained from the competent authority. The license for the development of the project has been granted by the Director, Town & Country Planning, Govt. of Haryana and no forest land is involved with the project. Copy of NOC issued from forest department, is enclosed as Annexure-VI. Yes, being complied. We are using STP treated water (after treatment so that it is fit for being used in construction activities and conforms to the Indian standard for Plain and Reinforced Concrete- Code of Practice (Fourth Revision)IS 456:2000) for carrying out construction activities at the project site. This STP treated water is purchased from HUDA STP as well as we procure STP treated water from our other operational projects through tankers. Please find attached periodic sample copies of the water tanker challans regarding STP water supply to the project site enclosed as Annexure-III. Potable water for construction laborers is being procured from HUDA through water tankers. periodic sample copies of the water tanker challans are enclosed as Annexure-IV. The project proponent will construct Yes, adequate no of rainwater harvesting pits rain water harvesting pits@1pit per will be constructed for the project for acre for recharging the ground water recharging the ground water. The site planwithin the project premises. storm water was enclosed as an Annexure II of our submitted initial compliance report Ref: UCC/ Sec 71/ MoEF-NRO /CR/ 2705 /2010 dated : 27.05.2010 Operation Phase: The STP shall be installed for the treatment of the sewage generated to the prescribed standards including odour and treated effluent will be The project is being developed in phase wise manner and for Phase-I of the project currently STP of 300 KLD will be installed. The waste water will be treated up to tertiary level and will ii. iii. iv. v. vi. vii recycled to achieve zero exit discharge. be reused for HVAC Cooling and irrigation The STP should be installed at the water for landscaping. The proposed water farthest place in the project area. balance of the project is enclosed as Annexure III of our initial compliance report Ref: UCC/ Sec 71/ MoEF-NRO /CR/ 2705 /2010 dated : 27.05.2010 Separation of the gray and black water Will be complied. Yes, Dual Plumbing line for should be done by the use of dual separation of fresh water and STP treated water plumbing line. Treatment of 100% gray will be provided. water by decentralized treatment should be done ensuring that the recirculated water should be have BOD maximum 10 ppm and the recycled water will be used for flushing, gardening and DG set cooling. For disinfections of the treated Yes, ultra violet radiation system will be wastewater ultra violate radiation or adopted as per the requirement. ozonization should be used. The solid waste generated should be The solid waste generated from the complex properly collected and segregated Bio- will be managed as per MSW Rule, 2000. The degradable waste will be decomposed segregation of solid waste will be primarily at at site and dry/inert solid waste should source. Sufficient no. of collection bins will be be disposed off to the approved sites provided at all strategic locations. The solid for land filling after recovering waste will be brought to a centralized collection recyclable material. facility and stored in segregated way. The solid waste generated will be handed over to authorized vendor of MCG/HSPCB/MoEF for further segregation, treatment and disposal at the site identified by HSPCB. Diesel power generating sets proposed All the DG sets provided for the power backup as source of backup power for lifts, purpose of the project will be acoustically common area illumination and for treated and will conform to rules made under domestic use should be of enclosed Environment (Protection) Act for air and noise type and conform to rules made under emission standard. The provided DG sets will the Environment (Protection) Act, use low sulfur content HSD. 1986. The location of the DG sets The stack height will be kept as per CPCB should be in the basements as promised norms. by the project proponent with appropriate stack height i.e above the roof level of the building as per the CPCB norms. The diesel used for DG sets should be of Low Sulphur contents (maximum 0.25%). Ambient Noise level should be Will be complied. Noise quality reports controlled to ensure that it does not showing ambient noise level is enclosed as exceed the prescribed standards both Annexure II are also. within and at the boundary of the Proposed Commercial Complex. The project proponent should maintain Yes, the green belt will be developed preferably viii. ix. x. xi. at least 20% as green cover for tree plantation especially all around the periphery of the project and on the road sides preferably with local species so as to provide protection against particulates and covered with vegetation/grass. The Project Proponent shall provide green cover in the paved area. Weep holes in the compound front wall shall be provided to ensure natural drainage of rain water in the catchments area during the monsoon period. The project proponent shall setup rain water harvesting pits@ 1 pit/acre having 400mm bore and 200mm slotted pipe as proposed for roof runoff and surface runoff, as per plan submitted should be implemented. Before recharging the surface run-off, pre-treatment must be done to remove suspended matter, oil & grease. The bore well for rainwater recharging should be kept at least 5mts. above the highest ground water table. The ground water level and its quality should be monitored regularly in consultation with Central Ground Water Authority. with local species so as to provide protection against particulates and covered with vegetation/grass in the operation phase. Please refer to Annexure-V for details of trees planted at the project site. Will be complied. Natural drainage of rain water will be maintained during the monsoon period for the project. Will be complied. Rain water will be recharged into the ground water only after removal of suspended matter by disilting chamber. The borewell for recharging the will be kept 5 m above the highest ground water table. The site plan-storm water is already submitted as an Annexure V of our initial compliance report. Ref: UCC/ Sec 71/ MoEF-NRO /CR/ 2705 /2010 dated : 27.05.2010 There is no borewell present at the project site. Currently, we are using STP treated water (after treatment so that it is fit for being used in construction activities and conforms to the Indian standard for Plain and Reinforced Concrete- Code of Practice (Fourth Revision)IS 456:2000) for carrying out construction activities at the project site. This STP treated water is purchased from HUDA STP as well as we procure STP treated water from our other operational projects through tankers. Please find attached periodic sample copies of the water tanker challans regarding STP water supply to the project site enclosed as Annexure-III. Potable water for construction laborers is being procured from HUDA through water tankers. periodic sample copies of the water tanker challans are enclosed as Annexure-IV. There should be no traffic congestion Proper traffic network inside the complex will near the entry and exit points from the be developed. Parking will be fully internalized roads adjoining the proposed project and no public space will be proposed to utilize. xii. xiii. xiv site. Parking should be fully The parking plan of the project is already internalized and no public spaces enclosed as an Annexure VI of our initial should be utilized. compliance report. Ref: UCC/ Sec 71/ MoEFNRO /CR/ 2705 /2010dated : 27.05.2010 A report on the energy conservation In the operational phase, appropriate energy measures confirming to energy conservation measures and management plan conservation norms finalize by Bureau will be adopted in order to minimize the of Energy Efficiency should be consumptions of non-renewable fuel. prepared incorporating details about building materials and technology, R CFL will be used in place of and U factors, etc and submitted to incandescent lamps in office, common SEIAA, Haryana in three months time. areas and parking. Lighting and switching of common area shall be designed keeping in mind day light integration. Roof insulation shall be planned to conserve energy. D.G. sets would be provided with auto cut and auto start mechanism. The water supply pumping system shall be provided with variable speed drive to conserve energy at part load. Space heating load will be minimized using passive solar structures. Building will have appropriate design to shut out excess heat and gain loss. Energy conservation measures like Installation of CFLs/TFLs for lighting the area installation of CFLs/TFLs for lighting will be integral part of the project design. the area outside the building should be Used/damaged CFLs will be stored separately integral part of the project design and from domestic waste and will be handed over should be in place before project periodically only to Authorized Vendor. Solar commissioning. Used CFLs and TFLs lighting feasibility will be explored for the should be properly collected and project. disposed off/sent for recycling as per the prevailing guidelines/rules of the regulatory authority to avoid mercury contamination. Use of solar panels may be done to the maximum extent possible. The solid waste generated should be The solid waste generated during the properly collected and segregated as operational phase will be properly collected and per the requirements of the MSW rules, segregated as per the requirements of the MSW 2000 and as amended from time to rules, 2000 and as amended from time to time. time. The bio-degradable waste should be composted at the site ear marked The details of solid waste management plan within the project area and dry/inert proposed for the project have been submitted solid waste should be disposed off to already. the approved sites for land filing after recovering recyclable material. xv The provision of the solar water heating system shall be as per the norms specified by HAREDA and shall be made operational in each building block. xvi The project proponent will use the water from the tube well for domestic purposes and commercial purpose only after getting permission from CGWA or will use water supply from municipality whichever is earlier during operational phase. xvii The traffic plan and the parking plan proposed by the project proponent should be adhered to meticulously with further scope of additional parking for future requirements. There should be no traffic congestion near the entry and exit points from the roads adjoining the proposed site. Parking should be fully internalized and no public space should be utilized. xviii. The project proponent shall comply with the ECBC norms. PART –B. GENERAL CONDITIONS i. The environmental safeguards contained in the EIA/EMP Reports should be implemented in letter and spirit. ii. Six monthly compliance reports should be submitted to the HSPCB and Regional Office, MoEF, GOI, Northern Region, Chandigarh and a copy to the SEIAA, Haryana iii. The SEIAA, Haryana reserves the right to add additional safeguard measures subsequently, if found necessary. Environment clearance granted will be revoked, if it is found that false information has been given for getting approval of this project. iv. All other statutory clearances such as approvals for storage of diesel from Chief Controller of Explosives, Fire Department, Civil Aviation Department, Forest Conservation Act, 1980, Wildlife Act 1972, PLPA, 1900, Forest Act, 1927, etc. shall be obtained, as applicable by project Since the project is a commercial (Office cum Retail) complex, there is no requirement of hot water. During the operational phase we will take HUDA water supply after taking the required permissions. Proper traffic network inside the complex will be developed. Parking will be fully internalized and no public space will be utilized. The parking plan of the project is already enclosed as an Annexure VI of our initial compliance report. Ref: UCC/ Sec 71/ MoEF-NRO /CR/ 2705 /2010dated : 27.05.2010 The building has been planned incorporating energy efficiency measures. Yes, Adequate environmental safeguards will be implemented for the proposed project in a time bound and satisfactory manner. Being complied. We are committed to abide by the additional safeguards if suggested by the SEIAA, Haryana in future as far as applicable and technically feasible of compliance. The construction in the project will be as per the documents submitted to SEIAA, Haryana. We are committed to fulfill all the project related rules and regulations and prior approval from statutory body. v. proponents from the respective authorities prior to construction of the project. The project proponent will not violate We will not violate any judicial any judicial orders/pronouncements order/commitment issued by the Hon’ble issued by the Hon’ble Supreme Supreme Court/High Courts. Court/High Courts. CURRENT STATUS OF PROJECT 1 Construction status of the project till Please refer the enclosed construction schedule date as Annexure VI for your ready reference. 2 Actual Expenditure incurred on Please refer to the enclosed expenditure on Environment Management till date. Environment Management on the project as Annexure VII. Actual Expenditure on the Project Please refer to the enclosed expenditure on project as Annexure VIII. Approved Site Plan Please refer Annexure IX for the approved site plan. 3 4. Annexure I (HEALTH CHECK-UP CERTIFICATE) Annexure II (ENVIRONMENTAL MONITORING REPORT) Annexure III STP TREATED WATER CHALLAN Annexure IV POTABLE DRINKING WATER CHALLAN Annexure V TREE PLANTATION DETAILS List of Trees Planted at Unitech Commercial Centre, Sector71, Gurgaon S.NO. 1. 2. 3. 4. Name Plumeria Ficus Alsconia Delonis Total Nos. 50 10 25 08 93 L Annexure VI CONSTRUCTION STATUS Annexure VII EXPENDITURE ON EMP EMP COST “UCC, Sector-71, Gurgaon Items a. b. c. d. e. f. g. h. Air Pollution Control Measures Water Pollution Control Measures Noise Pollution Control Measures Monitoring Rain Water Harvesting Green Belt Fire Management Miscellaneous Total Proposed Budget Expenditure Details till Estimates for Next two date (in lakhs) year (in lakhs) NonNonRecurring Recurring recurring recurring 1.75 4.0 1.0 55.0 1.75 2.0 1.0 71.31 0.85 1.0 0.5 55.0 6.00 ------------------------------0.9 11.25 ----------------1.00 0.40 0.84 9.24 3.0 5.0 2.0 3.50 1.80 17.80 -------26.0 78.86 589.0 50.0 925.17 Annexure VIII ACTUAL EXPENDITURE OF THE PROJECT Expenditure on the Project “Unitech Commercial Center”, Sector-71, Gurgaon S.No. Name of Work Total Achieved Till date (in Lacs) A PRECONSTRUCTION WORKS i. G.I. Fencing/ Barricading with G.I. Sheet 17.86 ii. Site Office (Porta Cabin with Civil works) 6.00 iii. D.G. Set/ Office Furniture/ Development - iv. Temporary Lighting 4.50 v. Peripheral Roads 9.73 vi. Approach Road - vii. Hard Landscape - viii. Soft Landscape - ix. Survey & Setting out - x. Peripheral Pipe Line - xi. Electrical Line Shifting - xii. Misc. Works 4.91 B BUILDING WORKS i. Civil Works 1140.0 ii. Excavation 49.00 iii. Aluminium Works - iv. Dampers - C SERVICES i. Electrical works - ii. Fire Fighting - iii. Plumbing Works - iv. HVAC Works - D.G. sets - v. Basement Ventilation - vi. Electrical Sub-station Works - a vii. Lift Works - viii. Fire Check doors - ix. D.G. Set Enabling works - x. Electrical Conducting Work 2.00 xi. Security/BMS - xii. Solar Hot Water Generation System/R.O. - D DEVELOPMENT OF LAND i. Soil Investigation 6.73 ii. Hard Landscape - iii. Soft Landscape - iv. External Electrical Works - v. Boundary Wall 8.44 vi. External Services (Storm, Sewerage, garden hydrant) - vii. S. Pool Pumps, Filtration Plant & equipment - viii. Pump room, water supply & treatment plant - ix. Sewage Treatment Plant (Civil Works) - x. Sewage Treatment Plant - E UNITECH SUPPLY i. Steel 2399.04 ii. Cement 37.98 iii. Ready Mix Concrete 1652.27 iv. C.P. Fittings/ China ware 31.55 v. Electrical Fixtures & Fittings - vi. Wooden Flooring - vii. Doors with Hardware fittings - viii. Stone/Pavers/ kerb stone (for model site) - ix. Ceramic Tiles/ Vitrified Tiles - x. Modular Kitchen/ Equipments/ Bath-tub/ shower - xi. D.G. Sets - F MISCELLANEOUS WORKS - i. Signage - ii. Maintenance Equipment - iii. Fountains/ Water Bodies - iv. EPBAX - v. Art Work - Interior of atrium - vi. Misc. Expense 100.82 vii. Service Tax/escalation 423.12 G EWS - H CONSULTANT’S FEE - a. GRAND TOTAL 5893.95 Annexure VIII APPROVED SITE PLAN