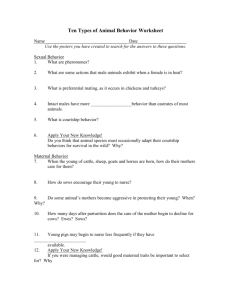

Veterinary Drug Order / Authorization / Prescription Worksheet

advertisement

Veterinary Drug Order / Authorization / Prescription DR. Good Vet NAME OF PRACTICE ADDRESS OF PRACTICE CITY, STATE, ZIP PHONE NUMBER’S For: (Name of Beef Operation) . DATE: Date Extended: Effective for 60 days unless otherwise noted: Vets Date Initials: Extended: SIG: Vets Initials: Date Extended: Vets Initials: Product Trade or Generic Name Special Instructions, (Handling, Limits, Comments) (No Substitutions) Withdrawals will be found in the Treatment Book Includes all products that have a withdrawal time … This include feed additives, injectable and oral medications (antibiotics, vitamins, supportives), vaccines, pesticides (individual animal and premise) NOTE: The label directions for use for ALL feed additives and feed medications must be strictly followed … they can not be used other than as directed on the label The following examples provide illustrations on how treatment instructions can be provide by the cattle owner’s veterinarian that meet FDA-CVM guidelines for using prescription medications. (Items listed are to serve only as an example for the veterinarian to follow in developing his unique protocol.) DR. Good Vet NAME OF PRACTICE ADDRESS OF PRACTICE CITY, STATE, ZIP PHONE NUMBER’S NAME BEEF OPERATION TREATMENT PROTOCOL BOOK This protocol is valid only if accompanied by a valid Veterinary Prescription THINK SAFETY: Safety of yourself, the others your are working around, the animal(s), & the food !!! NOTE: NEVER GIVE INJECTIONS IN THE RUMP OR ROUND, NEVER EXCEED 10CC/ IM INJECTIONS SITE Give ALL IM injections ahead of the shoulder neck. Withdrawal times should be calculated from the last day of treatment and use the longest time listed. DATE: Date Extended: Effective for 60 days unless other wise noted: SIG: Dealing with Non-performing Cattle … VERY IMPORTANT Non-performing cattle are a HIGH RISK for causing a violative residue problem. Non-performing cattle should have records reviewed by both the veterinarian and manager before being released for salvage. Establish a minimum withdrawal (WD) time that reflects the longest WD for any of the products administered. Animals recovering from illness may have organ damage that interferes with the normal clearing of medications. A residue-screening test such as the Live Animal Swab Test (LAST) test may offer a margin of comfort if these cattle need to be shipped close to their withdrawal time. Establish a residue-screening program for non-performing animals before releasing them for salvage. Needles should have hubs of the quality designed to not allow the needle to break off in the animal. Metal hubs are generally considered to the standard for excellent quality but some studies indicated plastic hubs may be superior. Change needles frequently (10 to 15 head) Change needle if contaminated or damaged. Never straighten a needle… the second time it bends there is a chance it will break. 18 to 16 gauge ½ to ¾ inch needles work well for SQ 18 to 16 gauge 1 to 1 ½ inch needles work well for IM NEVER INJECT ANYTHING BEHIND THE SLOPE OF THE SHOULDER !!! NEVER EXCEED 10CC / IM SITE !!! 1 On Each Treatment Record Include The Following: DATE, ANIMAL ID, PRODUCT(S) USED (record serial numbers) DOSE (never more than 10cc/site IM unless otherwise indicated and never inject rump or round) INDICATED WITHDRAWAL TIME. WITH DAY PRODUCTS & ROUTE OF ADMINISTRATION DRAWAL 1 Super Drug 1.1cc / CWT SQ 18 Days 2-10 RTP and Observe closely for proper response 1 Non-response –re-examine, treat with Fall Back Drug 3 cc / CWT SQ 44 days 2-3 If improved. Return To Pen (RTP); then observe in home pen 1 If no improvement – Fall Back Repeat 3cc/CWT (realize after WD COMMENTS: The animals pulled in this category are pulled because of holding back from feed, are usually active but mildly depressed and may have a high early fever (T 105-107 F) or a mild fever (T 103-105 F). Following treatment they will be put in a “3-day sick pen” for recovery and not retreated daily. They will be observed daily but not handled or hassled until they are evaluated on the third day. If much improved, observe the fourth day for continued improvement and Return To Pen (RTP). If not improved, move to the “Non-Performer” pen for veterinary service and management to examine. DIAGNOSIS Pneumonia / Early DIAGNOSIS DAY PRODUCTS & ROUTE OF ADMINISTRATION WITH DRAWAL Lidocaine, give as outlined on the castration & dehorning guide, 5 to 10 CC per horn or spermatic cord using a 1/2" to 5/8” 18 g needle. 21 Days Meloxicam, give 3, 15 mg tablets / CWT orally using the meloxicam dosing device. COMMENTS: Follow the attached guide for giving the local anesthetic, LIDOCAINE. Next give the MELOXICAM pain medication orally using the meloxicam dosing devise provided. Castration & Dehorning Pain Management 1 (additional examples) WITH DIAGNOSIS DAY PRODUCTS & ROUTE OF ADMINISTRATION DRAWAL Water-belly 1 Call Veterinary Service COMMENTS: Water-belly (urethral obstruction) cattle present with mild colic, slight straining and restlessness. The suspect animal should be rectally palpated to establish enlargement of the bladder and pulsing urethra. If a stone is obstructing an animal from urinating it is important to surgically remove it before it causes the bladder to rupture. Therefore, treatment should not be instituted until a positive diagnosis is obtained. Call veterinary service. Uterine Prolapse 1 Retained Placenta 1 Call Veterinary Service If cow not sick = Do nothing Infuse Uterus, Oxy100 30cc 36 Days Biomycin200 4.5cc / CWT COMMENTS: Most retained placenta will drop without intervention. Intervention must be approached with caution. More damage and infection can be created than the retained placenta causes. Do not attempt to remove a retained placenta for at least 10 days post calving. Bring the case to the attention of veterinary service if the animal shows any signs of depression. 1 The “4 S’ … Safety of yourself, Safety of the people you are working with, Safety of the animal(s) and Safety of the food supply. It is crucial to your success in working around livestock to establish a working relationship with the operation’s and management and personnel early when beginning your work with the operation. You should know what they want you to accomplish and what to expect from you. If you and the personnel are not on the same page, your presence can jeopardize your safety, their safety, the safety of the animal(s) you are working with and/or the safety of the intended food use of the animals you are working with. The "4 S's" … Safety is your most important objective: safety for yourself, safety of the people you are working with, safety of the animal(s) you are working with and safety of the intended food product from which the animals will are being raised to produce. Remember you are working with food and there are three food safety targets in the USDA-FSIS Hazard Analysis Critical Control Points (HACCP) food safety program. These are biologic, chemical and physical safety defects. 2 For our part, understanding safety, being able to recognize unsafe conditions and helping others to understand safety when handling products and animals is critical. In addition, the importance of preventing CROSS CONTAMINATION of feces, chemicals and metal to livestock feed is also critical. HACCP can have a much broader application. HACCP has been used by generations of people to protect their safety. Every generation has used the principles to ensure their families safety. For example consider a physical hazard. If a young child is playing in the front yard of a home, what is the hazard? Going in the street and being hit by a car would be one hazard. What would be a critical control point? Building a fence, sit in the yard with the child to catch it be for it got into the street … There are several ways to address the potential hazard. But by taking time to figure out what might go wrong, then figuring out how to prevent, reduce or eliminate the hazard will complete the HACCP plan. Similarly, the system is applied in the home. What is a chemical safety hazard in the home? Chemical under the sink … Controlled by a child safety lock on the cabinet door. What is a biologic hazard? Bacteria contaminating food before and/or during preparation … Controlled by washing preparer’s hands and cooking at the proper temperature of the required time. Taking time to evaluate the potential safety hazard(s) that exist when working with livestock is an important “what can go wrong” first step. Figuring out how to avoid having something that jeopardizes safety go wrong is the important next step. If these two items are continually being evaluated in light of the “4 S’s” the likelihood of accidents will be decreased. Cattle Product Safety Use Guide BQA Document by Dee Griffin, University of Nebraska, GPVEC; Revised June 2014 PROPERLY TRAINING FOR HANDLING ALL PRODUCTS IS CRUCIAL! Vaccines Modified Live Virus (MLV) o Minimal Risk Most if not all fit in this category. o Dangerous None recognized. o Safety Action If Exposed: Wash exposed / injected area and treat with a topical antibacterial ointment See a doctor if swelling or pain develops. Modified Live Bacterial (MLB) o Minimal Risk: None. o Dangerous: All have the potential to cause disease in humans. o Safety Action If Exposed: See a doctor immediately and take the label / bottle of vaccine with you. The doctor will likely begin treatment with an appropriate antibiotic. Killed (virus/bacteria) o Minimal Risk: Most if not all fit in this category. o Dangerous: None recognized. o Safety Action If Exposed: Wash exposed / injected area and treat with a topical antibacterial ointment See a doctor if swelling or pain develops. Medications Injectable and Oral: o Minimal Risk: Most fit in this category. A potential allergic response in some individuals. People with known allergies to one or more antibiotics should not work in areas in which animals are being treated … OR remove the class of antibiotics for which they are allergic from the treatment protocol and 3 thoroughly clean the treatment area to remove remaining traces of the offending antibiotic before the person works in the area. o Dangerous: Micotil If injected has been associated with human fatality. If Micotil is accidentally injected, apply to ice to injection site, seek immediate medical attention, take label to ER/attending physician, and contact Rocky Mountain Poison Control (1-800-722-0987) as they always have the most current medical information. Do not load syringe until the animal is properly and adequately restrained. Use the “one-hand” SQ tented technique for giving injections. As per all injections … Micotil should be given ahead of the shoulder. As per all SQ injections … there is no BQA limit to the amount of Micotil that can be given in one site. Lutalyse (and other prostaglandins), PREGNANT WOMEN CAN/WILL ABORT OR GO INTO LABOR IF EXPOSED TO THIS MEDICATION … this product can be absorbed through the skin … therefore pregnant women should not handle a prostaglandin bottle, work in an area or touch equipment that may be contaminated with a prostaglandin. Dexamethasone PREGNANT WOMEN CAN POTENTIALLY ABORT OR GO INTO LABOR IF EXPOSED TO THIS MEDICATION. o Safety Action If Exposed: For products other than MICOTIL … wash exposed / injected area and treat with a topical antibacterial ointment and see a doctor if swelling or pain develops An accidental injection with MICOTIL should be treated as an extreme emergency … CALL 911 and rush person to the emergency room … however there is no known antidote. For pregnant women LUTALYSE (and other prostaglandins), and for pregnant women Dexamethasone … wash exposed / injected area AND see a doctor ASAP A person exposed to antibiotic or other medication for which they are allergic should see a doctor ASAP … if the allergy is severe will need to call 911. Antiparasitics Injectable: o Minimal Risk: Most fit in this category. No known allergies. Should a person develop an allergic like response they should see or be taken to a doctor ASAP … if the response is severe call 911 o Dangerous: None. o Safety Action If Exposed: Wash exposed area and contaminated clothing. Should a person develop an allergic like response they should see or be taken to a doctor ASAP … if the response is severe call 911 Pour-On/Topical/Oral: o Minimal Risk: Most fit in this category. Organophosphates potentially can be a serious hazard if handled improperly. No known allergies. Should a person develop an allergic like response they should see or be taken to a doctor ASAP … if the response is severe call 911 o Dangerous: Only organophosphates are considered dangerous unless an allergic like response should develop. o Safety Action If Exposed: Newer generation synthetic pyrethroids can cause a severe paraesthesia in some people depending on location of exposure. Wash exposed area and contaminated clothing. Should a person develop weakness, tremors or an allergic like response they should see or be taken to a doctor ASAP … if the response is severe call 911 4 DURABLE CURE, A management program that returns sick animals to a productive state and significantly reduces costly relapses. The goal of the DURABLE CURE program is two-fold: 1) A first-time treated animal is more likely to become a high-performing, profitable animal again; and 2) That animal stays with its group mates and does not suffer a disease relapse. D.A.R.T. An acronym for the four areas that MUST be thoroughly assessed and monitored, especially in high stress or cattle with a high risk of developing disease. DART stands for; Depression, Appetite, Respiratory index and Temperature. All four areas must be returning to normal before treatment is discontinued. It is very important to monitor the first three items on all cattle every day. Try to address an animal’s disease condition during the early stages. This will greatly improve the treatment response and minimize production loss associated with disease. Sick Animal Evaluation: Daily monitoring of animals undergoing treatment is a key factor in the success of the DURABLE CURESM program. If each DART element - Depression, Appetite, Respiratory index and Temperature - is normal, and the treatment cycle has been completed, then the animal is ready to its production group (medication withdrawals met as appropriate). If any one of the factors is not normal, then the animal MUST remain for treatment and evaluation. Questions or concerns about the animal’s treatment response should be discussed with your veterinarian. Depression: Depression is rated on four levels: normal, mild, moderate and severe. A normal animal is alert and moves with its group mates. Mild depression may include signs like droopy ears or head, but the animal is easily stimulated into normal behavior. Moderate depression means an animal appears listless and acts sore. It responds to stimulation but does not behave like its group mates. An animal with severe depression is too weak to walk and looks close to dying. Moving animals from its group to the treatment pen can influence behavior. An animal can easily move from severe depression to moderate or from moderate to mild. Cattle health checkers should carefully note the animal's behavior in the home pen and communicate that to the person responsible for treating the sick animal. Appetite: One of the first signs of many systemic diseases, such as respiratory, intestinal or severe reproductive infections can be loss of appetite. Animals are going off feed when they fail to show interest in feed. Watch your animal’s response to feed deliver. If they do not appear interested something may be wrong. Try to catch animals before they have been off feed long enough to lack fill and appear - gaunt. One of the goals of therapy is return to full appetite, so it's important to closely monitor animals being treated for disease. Animals with a full appetite will have a full rumen, and a normal shaped flank. Ideally, the animal should be weighed daily, but this is seldom practical. Respiratory Index: An additional sign of many systemic diseases is an irregular breathing pattern. This is especially true if the animal is suffering from respiratory disease. Its respiratory rate can be accelerated, its effort to take breaths can be exaggerated, and the depth of its breaths can be noticeably different. Essentially, an animal's respiratory index is abnormal when its rate, depth and effort differ from those of its normal group mates. The respiratory index is determined by observing respiratory effort, pattern of expiration and the rate of expiration. Unless the person responsible for medial treatments uses a stethoscope to listen to lungs, close visual observation is a must. Temperature: The normal temperature of a healthy cow or calf is approximately 102.5° F. The temperature can is influence not only by disease, but by the animal’s environment, housing, and temperament. Remember if appropriate; adjust your definition of normal temperature to account for these factors. Rectal temperature is influenced by a number of factors. However, an animal with a temperature of 104° F or higher that also has abnormal depression, appetite and respiratory index scores probably is suffering from an infective process than will require additional evaluation and potential medical treatment. Measurement of temperature should be performed at a time of day - early morning or early evening - when it's least likely to be influenced by ambient temperature. Temperatures of infected animals tend to spike and respond quickly once treatment begins. But the animal's temperature must remain normal day after day, which requires monitoring the animal for at least three consecutive days. 5 BIOSECURITY Biosecurity is a practice designed to prevent the spread of disease by minimizing the movement of biologic organisms (viruses, bacteria, rodents, etc.) onto and within your operation. Biosecurity can be very difficult to maintain because the interrelationships between management, biologic organisms and biosecurity are very complex. While developing and maintaining biosecurity is difficult it is the cheapest, most effective means of disease control available and no disease prevention program will work without it. INFECTIOUS DISEASES CAN BE SPREAD BETWEEN OPERATIONS BY: the introduction of diseased cattle or healthy cattle incubating disease, introduction of healthy cattle who have recovered from disease but are now carriers, vehicles, equipment, clothing and shoes of visitors or employees who move between herds, contact with inanimate objects that are contaminated with disease organisms, carcasses of dead cattle that have not been disposed of properly, feedstuffs, especially high risk feedstuff which could be contaminated with feces, impure water (surface drainage water, etc), manure handling and aerosolized manure and dust, non-livestock (horses, dogs, cats, wildlife, rodents, birds and insects). DEVELOP AT BIOSECURITY RESOURCE GROUP An important first step is to develop a biosecurity resource group / team. Include those that may have special knowledge in control of biologic organisms. Generally beef operations have been open to vehicle traffic and visitors. Biosecurity has three major components: Isolation, Traffic Control and Sanitation. Isolation refers to the prevention of contact between animals within a controlled environment. The most important first step in disease control is to minimize commingling and movement of cattle. This includes all new purchases as well as commingling between established groups of cattle. Even in operations that have high cattle turn over such as feedlots, keeping feeding groups from mixing is an import biosecurity measure. Isolate feedlot hospital cattle and returned them to their home pen as soon as possible. Long acting therapies have improved our ability to minimize movement of infectious organisms between groups. An important biosecurity action on ranches is to separate cattle by age and/or production groups. Facilities should be cleaned-up and disinfected appropriately between groups. Traffic Control includes traffic onto your operation and traffic patterns within your operation. It is important to understand traffic includes more than vehicles. All animals and people must be considered. Animals other than cattle include dogs, cats, horses, wildlife, rodents, and birds. The degree of control will be dictated by the biology and ecology of the infectious organism being addressed and the control must be equally applied. Traffic control within the operation should be designed to stop or minimize contamination of cattle, feed, feeding handling equipment and equipment used on cattle. Pit silos should not be accessible from non-feed handling equipment such as loaders used outside the feeding area or vehicles that travel outside the feed mixing and handling facility. No one (manager, nutritionist, veterinarian, banker … no one) should be allowed to drive onto the surface of a trench silo. The only equipment allowed should be the loader used for handling the feedstuff. In large pits it may be acceptable to allow feed trucks to enter provided they are loaded at least 100 feet away from the working face of the stored feed. If possible, separate equipment should be used for handling feedstuffs and manure. Vehicles and employees should not travel from the dead cattle area without cleaning and disinfecting. The dead animal removal area should be placed in a location that allows rendering trucks access without cross-contaminating healthy cattle. Vehicle cleaning areas are becoming more common in commercial feedlots. Unfortunately they are frequently only used for trucks and heavy equipment. Management should consider extending a decontamination policy to other vehicles (especially tires) that are used across biosecurity control areas on the operation. Sanitation addresses the disinfection of materials, people and equipment entering the operation and the cleanliness of the people and equipment on the operation. The first objective of sanitation is to prevent fecal contaminates from entering the oral cavity of cattle (fecal – oral cross contamination). Equipment used which may contact cattle’s oral cavity or cattle feed should be a special target. The first objective in sanitation is to remove organic matter, especially feces. Blood, saliva, and urine from sick or dead cattle should also be targeted. All equipment that handles feed or is introduced into the mouth of cattle should be cleaned, including disinfection as appropriate, before use. Loaders used for manure or dead cattle handling must be cleaned thoroughly before use with feedstuff. It would be best if different equipment could be used. Minimize the use of oral equipment and instruments such as balling guns, drench equipment, and tubes. If used at processing and treatment thoroughly clean and disinfected between animals. Store cleaned equipment in clean, dry areas. Avoid storage in tanks or containers containing disinfectants. 6 Guide for Judicious Use of Antimicrobials in Cattle 1. Prevent Problems: Emphasize appropriate husbandry and hygiene, routine health examinations, and vaccinations. 2. Select and Use Antibiotics Carefully: Consult with your veterinarian on the selection and use of antibiotics. Have a valid reason to use an antibiotic. Therapeutic alternatives should be considered prior to using antimicrobial therapy. 3. Avoid Using Antibiotics Important In Human Medicine As First Line Therapy: Avoid using as the first antibiotic those medications that are important to treating strategic human or animal infections. 4. Use the Laboratory to Help You Select Antibiotics: Cultures and susceptibility test results should be used to aid in the selection of antimicrobials, whenever possible. 5. Avoid Combination Antibiotic Use: Combination antibiotic therapy is discouraged unless supported by sound science! 6. Avoid Inappropriate Antibiotic Use: Confine therapeutic antimicrobial use to proven clinical indications, avoiding inappropriate uses such as for viral infections without bacterial complication. 7. Treatment Programs Should Reflect Best Use Principles: Regimens for therapeutic antimicrobial use should be optimized using current pharmacological information and principles. 8. Treat the Fewest Number of Animals Possible: Limit antibiotic use to sick or at risk animals. 9. Treat for the Recommended Time Period: To minimize the potential for bacteria to become resistant to antimicrobials. 10. Avoid Environmental Contamination with Antibiotics: Steps should be taken to minimize antimicrobials reaching the environment through spillage, contaminated ground run off or aerosolization. 11. Keep Records of Antibiotic Use: Accurate records of treatment and outcome should be used to evaluate therapeutic regimens and always follow proper withdrawal times. 12. Follow Label Directions: Follow label instructions and never use antibiotics other than as labeled without a valid veterinary prescription. 13. Extralabel Antibiotic Use Must follow FDA Regulations: Prescriptions, including extra label use of medications must meet the Animal Medicinal Drug Use Clarification Act (AMDUCA) amendments to the Food, Drug, and Cosmetic Act and its regulations. This includes having a valid Veterinary-ClientRelationship. 14. Subtherapeutic Antibiotic Use Is Discouraged: Antibiotic use should be limited to prevent or control disease and should not be used if the principle intent is to improve performance. 7