A Preliminary Study on Quantifying the Effectiveness of Ionic Liquid

advertisement

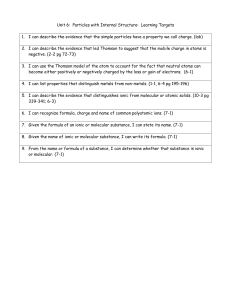

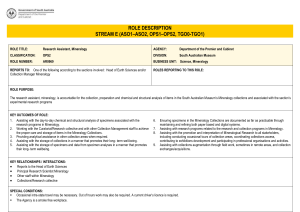

A Preliminary Study on Quantifying the Effectiveness of Ionic Liquid Metal Extraction from a Suite of Low Temperature, Variably Altered Magmatic Ni-Cu-PGE Sulfide Ores using Automated Mineralogy. SD Graham1*, Z Adeyemi2, DA Holwell2, GRT Jenkin2, AZM Al-Bassam AZM3, RC Harris3 and AP Abbott3. 1 Carl Zeiss Microscopy, Natural Resources Laboratory, Cambridge CB1 3JS, United Kingdom. shaun.graham@zeiss.com 2 University of Leicester, Department of Geology, University Road, Leicester LE1 7RH, United Kingdom. 3 University of Leicester, Department of Chemistry, University Road, Leicester, LE1 7RH, United Kingdom. ABSTRACT Ore recovery almost always requires the application of pyrometallurgical and/or hydrometallurgical techniques. These techniques, whilst effective, have a high energy demand and therefore impart a subsequent operating cost during recovery and waste treatment. As such, there has always been a desire to establish a technique that is more energy efficient and environmentally sustainable. The development and application of ionic liquids, or ionometallurgy, serves as an attractive alternative. This paper introduces; ionic liquids, the development of Deep Eutectic Solvents (DES) and their application to mineral processing [1, 2]; and presents preliminary data from an investigation on the effectiveness of these liquids in recovering Ni, Cu and PGE’s from a continuum of variably low temperature altered magmatic Ni-Cu-PGE sulphide ores. The study involves full mineralogical characterisation of samples from the Northern Limb of the Bushveld Complex which, contain a continuum of alteration assemblages from primary pyrrhotite-pentlanditechalcopyrite through to complete low temperature altered samples of chalcopyrite-pyrite-millerite [3, 4]. The mineralogical characterisation was carried out using Mineralogic Mining [5], an automated mineralogy solution based on a Field Emission Gun (FEG) Scanning Electron Microscope (SEM) equipped with two Energy Dispersive Spectrometers (EDS) to produce quantitative bulk mineralogy data and also measured elemental assay and deportment data. Following the characterisation studies, the samples were introduced into the ionic liquids, and reanalysed using Mineralogic Mining. The results presented make a preliminary assessment of the effectiveness of the ionic liquids on dissolving the variable sulphide assemblages and thus the recovery of Ni, Cu and PGEs. References: [1] AP Abbott et al. (2011). Processing of metals and metal oxides using ionic liquids. Green Chemistry, 13, 471-481. [2] AP Abbott et al. (2014). Electrocatalytic Recovery of Elements from Complex Mixtures using Deep Eutectic Solvents. Submitted to Green Chemistry, 2014. [3] JW Smith et al. (2011). The mineralogy and petrology of platinum-group element-bearing sulphide mineralisation within the Grasvally Norite–Pyroxenite–Anorthosite (GNPA) member,south of Mokopane, northern Bushveld Complex, South Africa. Applied Earth Science (Trans. IMM. B), 120, 158-174. [4] JW Smith et al. (2014). Precious and base metal geochemistry and mineralogy of the Grasvally Norite– Pyroxenite–Anorthosite (GNPA) member, northern Bushveld Complex, South Africa: implications for a multistage emplacement. Mineralium Deposita, 49, 667-692. [5] SD Graham et al. (2015) An Introduction to ZEISS Mineralogic Mining and the correlation of light microscopy with automated mineralogy: a case study using BMS and PGM analysis of samples from a PGE-bearing chromitite prospect. Precious Metals ’15, Falmouth, UK. KEYWORDS Ionometallurgy, Ionic Liquids, Deep Eutectic Solvents, Automated Mineralogy, Mineralogic