Supporting Information for: Gross Actinide Preconcentration using

advertisement

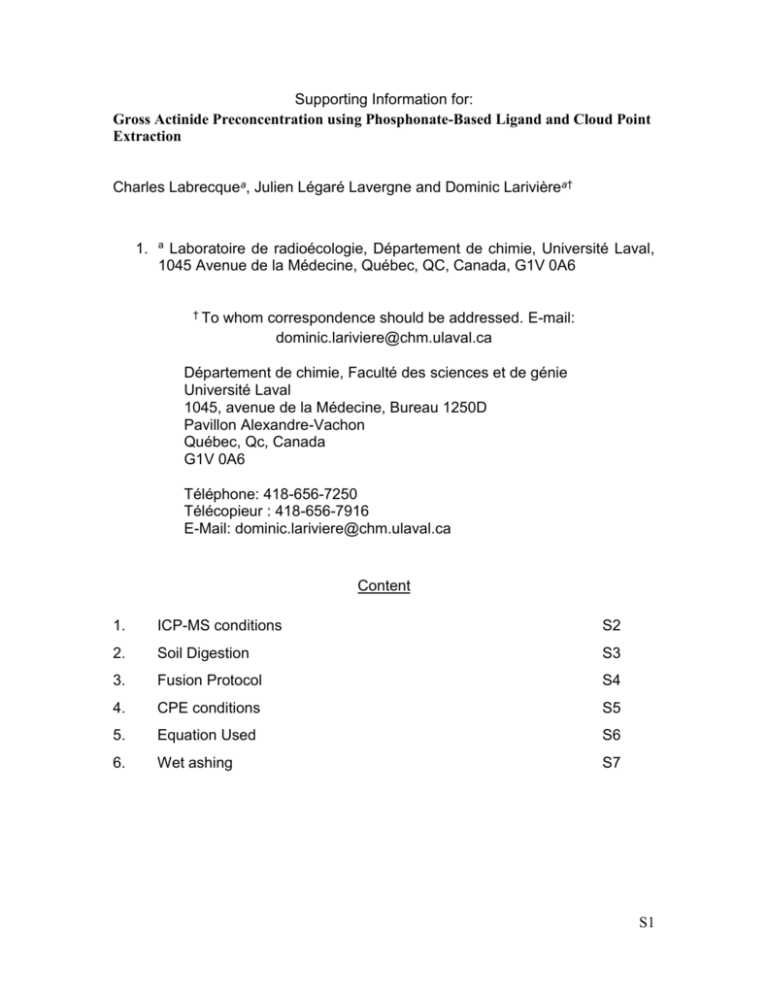

Supporting Information for: Gross Actinide Preconcentration using Phosphonate-Based Ligand and Cloud Point Extraction Charles Labrecquea, Julien Légaré Lavergne and Dominic Larivièrea† 1. a Laboratoire de radioécologie, Département de chimie, Université Laval, 1045 Avenue de la Médecine, Québec, QC, Canada, G1V 0A6 † To whom correspondence should be addressed. E-mail: dominic.lariviere@chm.ulaval.ca Département de chimie, Faculté des sciences et de génie Université Laval 1045, avenue de la Médecine, Bureau 1250D Pavillon Alexandre-Vachon Québec, Qc, Canada G1V 0A6 Téléphone: 418-656-7250 Télécopieur : 418-656-7916 E-Mail: dominic.lariviere@chm.ulaval.ca Content 1. ICP-MS conditions S2 2. Soil Digestion S3 3. Fusion Protocol S4 4. CPE conditions S5 5. Equation Used S6 6. Wet ashing S7 S1 ICP-MS conditions Table S1: ICP-MS conditions for actinide measurements. Tune Parameter Parameter Value Parameter Plasma Parameter Plasma Mode Hot Plasma Gas Flow Rate 15.1 L∙min-1 Auxiliary Gas Flow Rate 0.7 L∙min-1 Makeup Gas Flow Rate 0.44 L∙min-1 RF Power 1500 W Reflected Power >5 W Lenses Parameter (volts) Extract 1 Extract 2 6.7 -230 Omega Lens 27.2 Q1 Entrance -3 Q1 Exit Cell focus Deflect 2 -1.0 13.8 Value Cell parameters Use Gas False He flow 0.0 mL∙min-1 N2 flow 0.0 mL∙min-1 O2 flow 0% NH3 flow 0% OctP RF 150V Energy 5.0V Discrimination Q1 parameters (volts) Q1 bias -8.0 Q1 pre-filter -44.0 bias Q1 post-filter -26.0 bias S2 Soil digestion Soil solutions were prepared using fluxer digestion (0.5 g of soil was dissolved in 3.4 g of flux) for soil and sediments; solutions with high amounts of iron (such as red sludges) used a mix of LiMBO2/LiTBO2 (lithium metaborate and lithium tetraborate) (0.3 g of red sludge, 1.5 g of LiMBO2 and 1.5 g LiTBO2.The fluxes were purchased from Corporation Scientifique Claisse and are composed of ultrapure lithium metaborate : lithium bromide (98.5:1.5) and lithium tetraborate : lithium bromide (99:1).(Bouchard, M.; Rivard, S. Ness, S. ISO 9516-1 Simplified Borate Fusion & WDXRF Analytical Method for Iron Ores Analysis Including Exploration Samples; Technical Report from Corporation Scientifique Claisse: Quebec, QC, 2013) Lithium bromide was added to ensure that the flux would not stick to the crucibles. The protocol used for the fusion was a revised method from the one suggested by the manufacturer for the M4 Fluxer. (Table S3) but the same fusion parameters were used regardless of the flux mix used. The parameters used allowed for completely dissolved environmental samples on which cloud point extraction was attempted. Pouring of the fused sample into 100 mL 3 M HNO3 solution was preferred; this was found to be the optimal concentration to enhance the solubility of lithium metaborate and tetraborate and enhance the solubility of most metals in solution. After dissolution, the samples were clear solutions and were stable for weeks so did not require further filtration. Solutions were treated with PEG-6000 to eliminate the silica (Dai, X.; KramerTremblay S. Health Phys. 2011, 101, 144-147.) in solution, which could impact the analysis by clogging the ICP-MS nebuliser and limit the redispersion of the surfactant-rich phase containing the analyte. S3 Fusion Protocol Table S2 : Fusion Protocol Used for the Dissolution of Environmental Samples. Function Steps Time (min) Proposed Protocol 0 1 2 3 4 5 6 7 8 Total Pre-heating Oxidation First dissolution Cooling Heating Final dissolution Cooling Pouring Stirring 00:05 00:30 00:30 – 01:00 03:00 00:10 10:00 15:15 S4 CPE conditions Table S3: Optimised CPE system conditions 1 Parameters Conditions Units Sample 6.5 mL [HNO3] 0.1-2 M [TTX-114] 1.07 mmol L-1 [H2DEH[MDP]]1 165 µmol L-1 [CTAB] 100 µmol L-1 [KBr] 10 mmol L-1 [KBrO3] 1,5 mmol L-1 Textraction 4 °C Tphase separation 20 °C RCFaverage 4 700 G Concentration used for liquid samples, For soils a concentration of 825 µM was used. S5 Equations used The following figures of merit of the complete methodology were assessed for the optimal conditions of the method: minimal detectable activity, pre-concentration factor, detection limits, and quantification limits. The chemical recovery (CR, %) and pre-concentration factor (PF) by alpha spectrometry were determined using the following previously reported equations (Labrecque, C et al. Talanta 2013, 107, 284-291.): 𝐶𝑅 = 𝑃𝐹 = 𝐶𝑆𝑅𝑃 × 100 𝐶𝑠𝑝𝑖𝑘𝑒𝑑 𝐸𝑞. 1 𝐶𝑖𝑛𝑖𝑡𝑖𝑎𝑙 𝑉𝑖𝑛𝑖𝑡𝑖𝑎𝑙 − 𝐶𝑠𝑢𝑝𝑒𝑟𝑛𝑎𝑡𝑎𝑛𝑡 𝑉𝑠𝑢𝑝𝑒𝑟𝑛𝑎𝑡𝑎𝑛𝑡 𝐸𝑞. 2 𝐶𝑠𝑢𝑝𝑒𝑟𝑛𝑎𝑡𝑎𝑛𝑡 𝑉𝑠𝑢𝑝𝑒𝑟𝑛𝑎𝑡𝑎𝑛𝑡 where CSRP is defined as the activity in the surfactant-rich phase, Csupernatant is defined as the concentration in the supernatant after the phase separation, and Vsupernatant and VSRP are the volume of the supernatant phase after the phase separation and the redispersed surfactant-rich phase, respectively. In the recovery equation, the Cspiked is the concentration of the analyte that has been added to the solution. Chemical recovery was used to determine if the plutonium mass balance was near quantitative and to monitor the analyte recoveries for the analysis. Chemical recoveries (Eq. 1) are used to directly measure the quantities in the SRP. This differs from most strategies, which rely on a differential between the Csupernatant and Cinitial, and are of no interest for the analysis of real samples. (Pepper, S.E. et al. J. Radioanal. Nucl. Chem. 2009, 282, 909-912; Favre-Reguillon, A. et al. Talanta 2004, 63, 803-806.) S6 Wet ashing Wet ashing was used to provide a clean fraction of preconcentrated actinides. Various techniques of wet ashing were tried and HNO3:H2SO4 (5:1) was found to be the safest while both HNO3:H2SO4(H2O2) (5:1) and HNO3:HClO4 (5:1) were found efficient at digesting the SRP. S7