boating safe work procedure [doc file] - Marine Science

advertisement

![boating safe work procedure [doc file] - Marine Science](http://s3.studylib.net/store/data/006857024_1-6c8eda70511ae950ec2f506475d7a41e-768x994.png)

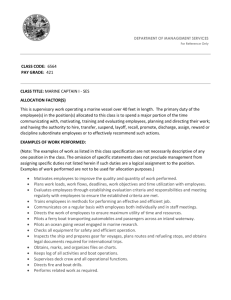

SWP For Macquarie University Vessels Boating Induction Operator appropriately qualified with NSW Maritime Boat license and inducted by Marine fieldwork manager. Vessels in survey and or registered, trailers registered, both regularly serviced Boat must not be operated outside its survey and crewing limits. Note the difference between the vessel operating as a dive vs work boat. As part of the induction the staff/student reads relevant SOP and SMS documents. Vessel must carry safety equipment as required by Maritime NSW for survey. All crew familiar with emergency procedures and operation of safety equipment. Crew Limits as a workboat Pelagica Skipper + 5 crew = 6 The master/crew must have sufficient training in the use of the vessel in the operating conditions upto 16 knots and 2m of swell in open waters. Manually inflated life jackets are to be worn in open waters SeaWasp Skipper + 4 crew = 5 The master/crew must have sufficient training in the use of the vessel in the operating conditions of 16 knots and 2m of swell open waters. Manually inflated life jackets are to be worn in open waters Jimble Skipper + 4 crew = 5 The master/crew must have sufficient training in the use of the vessel in the operating conditions of 16 knots in sheltered waters. Crew Limits as a Dive Boat Pelagica 5 persons note one less when operating as a work boat. Not to be left unattend during dive operations Daylight hours only for operation Vessel must be operated in full compliance Safety Management System SeaWAsp 4 persons note one less when operating as a work boat Not to be left unattend during dive operations Daylight hours only for operation Vessel must be operated in full compliance Safety Management System The Auxillary engine must be attached to the transom at all times when the vessel is in operation and is not to be steered from the marlin board. Predeparture Checklist Check weather conditions prior to departure. Before putting boat in water ensure bungs are in securely. Use the daily log as a checklist Prior to Departure Conduct a visual and operational inspection of equipment prior to departure utilising vessel daily use log as a checklist. Report and repair any faults ASAP Ensure sufficient fuel in tanks before setting out. Keep ropes coiled and stowed neatly inside the boat. Always keep a look out for shallow water and other obstacles in water. Report and repair any faults ASAP Master to cease operations if weather conditions deteriorate. Equipment failure The Marine fieldwork manager maintains a regular service of trailer, vessel and outboard. Sea Wasp and Pelagica are in commercial survey. Service records are maintained by MFWM Safety Equipment Communication, check marine radio and mobile phone coverage upon departure. If operating in open waters log in with marine rescue Channel 16. Check mobile phone coverage as a secondary communication device. Communication failure First aid and casualty evacuation Fieldwork party will have primary VHF radio use Channel 16 in an emergency, ensure aerial is up. Secondary means of communication as assessed in the planning stage including EPIRB and Mobile with Telstra 4G if using another service provider check coverage during the trip to be aware of potential blackspots . Any faults occurring with equipment must be reported immediately & alternative arrangements made. Fieldwork communication plan to be carried by the field party, the fieldwork manager and the contact person. Refuelling of vessel Avoid being splashed by fuel by standing in boat when refuelling. Avoid naked flame. Keep the fuel hose in contact with fill pipe to prevent electrical static build up. Be aware of Fuel stop cocks and the location of fire extinguishers and how to operate them in the event of an emergency. Check fuel filters are clear and drain if necessary Check extinguisher is in “green “and expiry. Areas of Operation Manually inflated life vests to be worn when heading offshore or upon request of Master Plying Limits for Individual vessels Pelagica Registered as a 2C vessel Area of operations for PELAGICA 15nm to seaward and laterally along the coast of NSW. Sea Wasp Registered as a 2C vessel Areas of Operation are within 5 nautical miles from the seaward limit of a safe haven. Attach trailer to vehicle Strained muscles from push/pull heavy weight use 2 or more persons where possible. Use correct manual handling techniques Pinch injuries to fingers, attention to the task and take care and not rushing job. Ensure safety chains attached, jockey well is raised and handbrake is off Insert R Clip into towball coupling. Check stern straps are in place. Check tyre pressure Avoid stowing loose items in boat Towing the Vessel During the induction process the MFWM will assess experience and ability in towing and reversing the trailer. Passengers to assist driver when reversing. When launching, driver to have window down. Launching/retrieval of vessel Before leaving vehicle apply handbrake, place in Park or in Gear turn off the vehicle. Observe conditions as boat ramps are slippery and act accordingly. Move carefully and slowly. The person managing the winch to be In view of master to signal that all is clear and ready for the boat to be driven onto or off the trailer. When launching have the master engage forward gear second operator releases the safety chain then release winch hook then communicates to the master that they are good to reverse. When winching, double check that the cable is locked off (i.e. can’t run free). When retrieving vessel the second person to stand at the rear corner of the vehicle allow master to drive boat onto trailer. When the vessel is in position the second person communicates with master on boat operation prior to winching boat on trailer. Avoid placing arms/limb between vessel and winch post. Then connect safety chain. Lower aerial When Starting Boat Check you have the keys Insert kill switch into to electrical stop button turn batteries on but leave the crossover closed. Ensure boat is neutral Check the water around the propeller is clear. Check for tell tales once motor has started Swamping of vessel/vessel overturning Weather will be checked and experienced operators at the helm. Winds should be less than 16 knots and less than 2m of swell. When operating offshore crew will wear manually inflated life jackets. Ensure navigational aids are working e.g. Chart plotter, GPS chart for the area. For unfamiliar areas it is good practice to carry charts of the waterway. Practice good seamanship at all times. Observe external boating hazards e.g. weather navigational signs, obstructions, traffic. Minimum of two persons on operational vessel. Unless prior approved by marine fieldwork manager. Stay with the vessel. The boat cannot be taken out unless ALL safety equipment is aboard and in good working condition. Use daily log checklist prior to departure. Man Overboard retrieval Operator awareness of conditions and acting according to these. Williamson turn training drills. Hit the Man Over Board Button on the GPS. Immediately turn the boat towards the side the person has fallen from. This will reduce the risk of the outboard hitting them. CONSCIOUS Designate one person to maintain visual contact and point out victims location at all times Hit way point on Chart Plotter, Gradually reduce speed. Conduct Williamson turn Secure throw line to vessel, deploy throw line or life ring. Throw line or life ring so that it cuts across line of person overboard. Approach person in water from lee (down, wind/current) side Exposure to Heatstroke/sunstroke/ Hypothermia Protection from sun (canopy). Appropriate personal protective equipment – sunscreen, appropriate hat, UV eye protection. First aid training for operators Operators to take appropriate food/drinks for expected weather conditions Wearing of appropriate personal protective equipment – thermals, neoprene gloves, hat, wet weather clothing, boat boots, and life jacket. Protection from rain (canopy). First aid training for operators. Operators to take appropriate food/drinks for weather conditions Sea Sickness Appropriate medication before journey. Brief then Monitor personnel throughout journey. Adequate fluid intake. Communicate ill feeling Stop work if necessary Cool patient and have stand at the stern. Work on charted vessels Induction on safety features of vessel by operator – e.g. fire extinguishers, Muster Points, EPIRBS, first aid kit, flares etc Vessel must be in survey and operate within these limits (see Maritime NSW). Vessel must be operated by suitably qualified person. MQ Staff and students to operate in accordance within SOP/SWP procedures. These guidelines will be sent to the MFWM. Completion of the trip Record Boating hours in the Daily use log. Thoroughly wash the boat and flush motors. Inspect hull and propeller for damage. Turn all batteries off Return Daily use log and report any maintenance issues to MFWM. Specific Boating Activities Pulling up mooring Lines Aware of mooring rope fouling propeller where possible be in neutral Where gloves to prevent abrasions from oysters and barnacles Skipper keeps watch for other boat traffic. Hydrophone recordings Master and crew to wear life jackets Engines will be off for recordings Boat will drift abeam to the sea therefore conduct recordings in less 1.0m of sea and swell Ensure hydrophone on board prior to staring engine. Plankton trawls Master and crew to wear life jackets Use of davit check prior to departure Check bilge pump to wash net is operational Keep body parts clear of ropes Ropes clear of propeller (float assisted) Listen for Masters requests Be aware of the extra weight whilst operating on the port side Ship to Shore operations Life Jackets to be worn Swell/wave height at Landing <0.5m Deckhand and personnel to assist with tender position tender on the lee side Board tender when master permits A person that has prior experience of landing at the site must lead the landing. The landing group should comprise at least 2 people. Appropriate foot wear to be worn. Briefing on the landing procedure given prior to entering the tender. Night Activities Wear a life jacket Ensure navigational lights are working and deck lights/torches. Check that crew know where all equipment is stowed. Deployment and Retrieval of equipment. Use an appropriate vessel for example SIMS SeaTamer Ensure the weight of the item to be deployed and retrieved does not exceed the Safe Work Load of the winch and davit. Wear a life jacket Staff and students to be inducted in the use of the davit and winch. LIVE BOAT DIVER PICKUP Rationale: In the following circumstances it would be preferable to pick up divers and or snorkelers from a boat idling in neutral rather than anchored and not running. When dive operations are close to shore, dives are short duration and or in deep water (>25m) or when searching for moorings when divers/snorkelers maybe required to relocate and get on and off the boat multiple times. Or in the event that divers become separated. Guideline: Ensure dive flag is raised. Brief divers prior to entering the water on the dive plan sea conditions etc. Divers are to remain together. Each diver is to have their SMB ready to inflate. In the event of an emergency the diver is to inflate the SMB, when the SMB reaches the surface they then give 3 sharp tugs. If divers are separated during the dive then they are to inflate their SMB upon ascent. Use a safety line and float divers descend and ascend on this line 1 They do not enter the water until the skipper instructs them. 2 The skipper will communicate that the vessel is “In Neutral” and they can enter the water. 3 Divers acknowledge by replying “In neutral”. 4 The divers enter from the windward side of the vessel. 5 Upon entering the water each diver turns and faces the skipper and presents the “OK” signal, skipper returns the signal to acknowledge. 6 The skipper then monitors diver location via surface float and bubbles at the surface, particularly important in high boat traffic locations. 7 Upon surfacing the divers and skipper make visual contact and display the “OK” signal. 8 The skipper then approaches the divers from the leeside. 9 Upon surfacing the skipper makes visual contact with divers instructs the divers the boat is “in neutral” Divers acknowledge the signal then approach boat. 10 Skipper assists with gear and loading divers.