display

advertisement

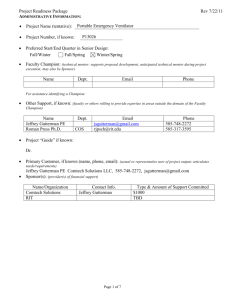

Project Readiness Package Rev 7/22/11 ADMINISTRATIVE INFORMATION: Project Name (tentative): Project Number, if known: Preferred Start/End Quarter in Senior Design: Fall/Winter Fall/Spring Winter/Spring Faculty Champion: (technical mentor: supports proposal development, anticipated technical mentor during project Ritter Arena: Heat Exchanger Between Cold and Warm Coolant Loops P13425 execution; may also be Sponsor) Name Dr. Mario Gomes Dept. ME Email mwgeme@rit.edu Phone 585-475-2148 For assistance identifying a Champion: B. Debartolo (ME), G. Slack (EE), J. Kaemmerlen (ISE), R. Melton (CE) Other Support, if known: (faculty or others willing to provide expertise in areas outside the domain of the Faculty Champion) Name Dept. Email Phone Project “Guide” if known: Dr. Mario Gomes (ME) mwgeme@rit.edu Primary Customer, if known (name, phone, email): (actual or representative user of project output; articulates needs/requirements) Richard Stein, HVAC System Engineering Support Manager, 585.475.4351, rdsfms@rit.edu Sponsor(s): (provider(s) of financial support) Name/Organization Contact Info. Page 1 of 8 Type & Amount of Support Committed Project Readiness Package Rev 7/22/11 PROJECT OVERVIEW: Tasked with reducing the carbon footprint and energy usage of RIT, we have focused on improving the Ritter Ice Arena, one of the largest energy consuming building on campus. Given the two resources of the cold water loop (enters at 36°F and leaves 32°F, needing to be heated back up to 36°F) and the warm water loop (enters at 65-90°F and leaves at 70-95°F, needing to be cooled back down), the goal is to reduce the energy usage of both systems. Using the waste cooling from one system and the waste heat from the other, install a heat exchanger to accomplish goal. As a commercial heat exchanger of 40 gpm provides too much temperature change, divert a portion of the water to go through the heat exchanger and back to mix with the other water. This small portion (the calculations on Edge use ~6.2 gpm) will be heated from 32°F to ~50-60°F and then reintroduced back into the pipe carrying 40 gpm where an average of 36°F will be obtained. Modify amount of heating by varying flow of both the warm and cold coolant inputs/outputs. DETAILED PROJECT DESCRIPTION: Customer Needs and Objectives: Customer Need # Importance Description CN1 5 Lower cost of heating/cooling CN2 5 Cost of modifications less than money saved CN3 5 Modifications must be sustainable (green) CN4 3 Aesthetically pleasing CN5 5 Safe for human operation CN6 5 Can be integrated into current system CN7 5 Maintain effective running conditions CN8 5 Low maintenance Page 2 of 8 Project Readiness Package Rev 7/22/11 PROPOSED CHANGE Page 3 of 8 Project Readiness Package Rev 7/22/11 Functional Decomposition: Page 4 of 8 Project Readiness Package Rev 7/22/11 RIT Campus Improvements Functional Interfaces Warm/Cold Water Heat Exchanger Dan Crossen Cold Water Input Warm water Input thermometer Cold Water Output thermometer pipe connection Sense Temperature (cold water) thermometer pipe connection data Sense Temperature (warm water) data data data Vary Pump Speed pipe connection Exchange Heat pipe connection thermometer data pipe connection Pump Water to Exchanger size Page 5 of 8 size Fit Into Space Warm Water Output Project Readiness Package Rev 7/22/11 Specifications (or Engineering/Functional Requirements): S1 S2 S3 S4 S5 S6 S7 S8 S9 Specification (metric) Unit of Measure Source Function CN6,7 CN6,7 CN6,7 CN6,7 CN1,3 CN6 CN1,3 CN7 CN1,3 CN5,6 System System System System System System System System System System Warm Water Temp Input Warm Water Temp Output Cold Water Temp Input Cold Water Temp Output Pump energy usage Pump flow Rate max Heat loss from pipes Pump time constant Pump efficiency Size of Equipment CN2 System System cost $$ CN5,6 System Weight lbs CN7,8 CN7,8 System System Operating conditions: temperature Operating conditions: relative humidity °F % °F °F °F °F KW gpm KW sec % inches S10 Marginal Value 24x24 x12 S11 S12 S13 S14 Page 6 of 8 60 Ideal Value Comments/Status 70-95 65-90 32 36 1-5 6.2 0-2 <1 60-100 12x12 x12 <= $1000 40 32-95 0-100 Ambient indoor ice rink Ambient indoor ice rink Project Readiness Package Constraints: o o o o Rev 7/22/11 Labview or equivalent program used in monitoring/running of system 5 year maximum payback Must not interfere with the running of the current system Must be integrate-able into the current system Project Deliverables: Working system (not installed in Ice Arena) complete with heat exchanger, pump(s), piping, temperature sensors, and LabView program Budget Estimate: $1000 Intellectual Property (IP) considerations: Other Information: Potential to save upwards of $15,000 per year, less pumping costs based on length of piping. If project is a success, installation will be required during the 2 months the ice is melted. Continuation Project Information, if appropriate: No prior projects. This project will be built using the knowledge, customers, and information obtained Spring, 2012. STUDENT STAFFING: Anticipated Staffing Levels by Discipline: Discipline EE How Many? 0 ME 3 CE 0 ISE Anticipated Skills Needed 0-1 ME1: Take care of the design of the flow of fluids. Model the flow of the fluid based off of given temperatures and properties. Choose applicable pump(s). ME2: Thermal modeling of the fluid flow. Analytically obtain flow needed to sustain desired output of 36°F based on input temperatures. ME3: Labview: Construct program to take in the input of the temperatures and output desired flow rates for both warm and cold water. Output the <input temps>, <output temps>, <warm flow rate>, and <cold flow rate> for data analysis. ISE1: Make sure that it will fit in the designed space. Construct a general design that will meet the size requirements obtained from observing usable space in the ice rink. Page 7 of 8 Project Readiness Package Rev 7/22/11 OTHER RESOURCES ANTICIPATED: Category Resource Available? Description Faculty ME consult (to help with hooking inputs and outputs into Labview) Environment MSD Design Center Machine Shop & Brinkman lab Senior Design Lab Equipment Materials Other Prepared by: Daniel Crossen Date: Page 8 of 8 5/22/12