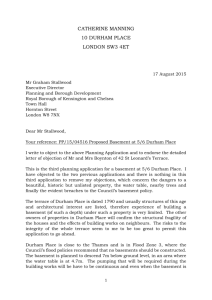

Report

advertisement

41-43 BEAUFORT GARDENS Structural – Construction Methodology 31/07/2015 Quality Management Issue/revision Issue 1 Remarks Stage 1 tender Revision 1 Date 08.05.2014 31.07.15 Prepared by RL AD AD AD AD AD Project number 24710685 24710685 Report number 01 01 File reference 07 / Specs 07/Specs Revision 2 Signature Checked by Signature Authorised by Signature Project number: 24710685 Dated: 31/07/2015 Revised: 2 | 10 Revision 3 41-43 Beaufort Gardens Structural – Construction Methodology 31/07/2015 Client Beaufort 43 Ltd Consultant WSP UK WSP House 70 Chancery Lane London WC2A 1AF Tel: +44 (0)20 7314 5000 Fax: +44 (0)20 7314 5001 www.wspgroup.co.uk Registered Address WSP UK Limited 01383511 WSP House, 70 Chancery Lane, London, WC2A 1AF WSP Contacts Alan Darling Peter Butler Rob Leland 3 | 10 Contents: Introduction Existing Building Outline Design Proposals 5 5 5 Site Constraints Geotechnical Assessment 7 7 7 Description of Site Substructure strategy and sequence 8 Superstructure sequence 9 Project number: 24710685 Dated: 31/07/2015 Revised: 4 | 10 Introduction: Existing Building: 41-43 Beaufort Gardens, formerly Parkes Hotel, is a privately owned boutique hotel in Knightsbridge, London SW3. It is part of a continuous terrace of Victorian town houses fronting the west side of Beaufort Gardens and is 6 storeys high with a part basement at lower ground level. It was built circa 1861-1870. The building structure is of load bearing masonry party walls, front and rear perimeter walls and internal spine and cross wall construction. Floors are generally spanning front to back on the front half of the building and from side to side on the rear half of the building. Floor investigations have shown that the floors are generally of timber joist and ply floor construction at all levels except the lower ground floor which is of reinforced concrete. The rear half of the building comprises 9 floor levels compared to the front which has only 7 levels. The brickwork of the rear elevation is modern and together with the rear half of the building was rebuilt totally in 1986. The floor levels at the front do not match those at the rear and stair access at the front and rear of the building link each floor. The existing lower ground floor is approximately 2.5m below ground floor which is raised about 0.4m above external pavement level. The lower ground floor is founded directly on the ground. At the front of the property are lightwells with access from pavement level to the lower ground level. The foundations to the internal and party walls have been investigated by trial pits and were found to be conventional brick and concrete strip footings under the load bearing perimeter, spine, cross and party walls. Outline Design Proposals: The proposals for conversion of the existing hotel to private residential accommodation include amongst other works, the creation of a new basement level below the existing lower ground floor. Underpinning is proposed to the party walls on all sides and now to the front façade of the existing building and will extend to the new basement level. Underpinning of the pavement vaults will also be required because the new lower ground floor level will be set below the existing lower ground floor level in the vaults to increase headroom and will undermine the foundations. The ground floor access at the front into the lower ground floor will be reconfigured with a new central stair access and a new lift core. The existing building has been demolished in advance of the main works, retaining the front façade. A portion of the rear section of wall adjacent to no 44 Beaufort Gardens has also been part retained for its full height where it flanks a void space behind no 44 Beaufort Gardens and rebuilt. The current design differs from that previously proposed in that the basic footprint of the basement layout is reduced. This is because the new basement will no longer extend under the existing front façade of the building and the pavement vaults. It will now stop at the rear of the front façade. As a consequence the need for a transfer beam (Pynford beam) is not required and the full height underpinning to the pavement vaults is also omitted. With a reduced basement, the amount of excavation is less and the piled foundations adjacent to the façade are simplified as a result. The front facade will however need to be underpinned but the nature of the revised substructure works as a whole has no greater impact than the previous proposals and in fact is likely to have less of an impact. Due to the reduction in excavation, the works are fully capable of being implemented in accordance with the already approved Construction Management Plan by WSP dated November 2010 approved under CON/12/03386. Summarising the key benefits: Reduced volume of bulk excavation Less piling works Less temporary works to support façade Reduction in basement slab concrete and reinforcement 5 | 10 Reduction in lorry movements Reduction in programme activities The new building superstructure is not changed from the previous submission and will be constructed as a reinforced concrete frame. It will have reinforced concrete core walls and columns which will be supported on the piled foundations and supporting reinforced concrete flat slabs at each floor level. Additional steelwork is required at roof level for an inclined mansard as well as at floor level to trim major openings through the slabs. Project number: 24710685 Dated: 31/07/2015 Revised: 6 | 10 Description of Site: Site Constraints: The building occupies the whole footprint of the site and the only external access to the building for removal/delivery of materials is at the front of the building either through the front door entrances or via the lightwells at the front into the lower ground floor. The quantities of materials to be removed from the required excavations and for the supply of new construction materials is likely to require the forming of a temporary opening through the front wall/window at ground and lower ground level. It may also be necessary to take up part of the ground floor at the front to permit this access. The appointed contractor will provide detailed methodology and logistics prior to undertaking the works Beaufort Gardens is a residential street and cul-de-sac with permit only street parking on both sides of the street. The parking bays in front of the property will need to be suspended for the duration of the works Party walls are shared on both sides of the property at no’s 40 and 44 Beaufort Gardens and to the rear at no’s 6 to 10 Beauchamp Place. Due to the presence of a perched water table and the level of the interface of Terrace Gravels with London Clay, it is planned that the depth of any excavation work and the need for any underpinning work will be within the Terrace Gravels and above the perched water table and avoids the need for any ground water pumping and the inherent and unacceptable risks of soil wash out from under the adjacent properties. Notwithstanding the fact that any new construction should be above the perched water table, it is envisaged that the basement slab, the lower ground floor slab and the perimeter walls will be constructed using a watertight membrane and waterproof reinforced concrete. Geotechnical Assessment: It was known from studies of the BGS maps of the area that the site geology consisted of Terrace Gravels over London Clay. This was then confirmed by the geotechnical site investigation in 2009. The upper levels of the Terrace Gravels consist of a covering of sandy silty clay overlying irregular layers of gravel and sand. The main founding strata for the existing building foundations are in the upper layers of the Terrace Gravels. The Terrace Gravels at depth are denser in both sand and gravel and provide a good medium for carrying increased loadings of the building (in the order of 200-250kPa). The depth of the Terrace Gravels is in the order of 6.5m below the existing lower ground floor level. Below this the London Clay will offer reduced bearing capacities and therefore any new works will need to be constrained within the depth of the existing Terrace Gravels. The party walls will be undermined by the development proposals and therefore must be underpinned to a depth within the Terrace Gravels and to below the proposed lower ground floor slab level. The construction of the new basement floor slab will be some 2m above the base of the Terrace Gravels. It is envisaged that both basement slab and perimeter walls will be constructed using a watertight membrane and waterproof reinforced concrete. The existence and depth of the perched water table is approximately close to the Terrace Gravel/London Clay soil interface at +0.15m OD but it is known from preliminary shaft construction works undertaken within the site to the proposed full depth of the development, that the excavation remained dry throughout to a depth of +0.5m OD. The proposed basement deepening will result in a global unloading of the soils below the excavation that will result in heave (upward movement). The basement excavation will result in the removal of about 100kPa from the soils below the site. This is less than that assessed for the previous larger basement layout. The underpinning works will place the building loads close to the top of the more compressible London Clay. The underpins to the party wall foundations will need to act as retaining walls in addition to carrying vertical loads. Deflection of the retaining wall into the site may result in settlement during the excavation works. This together with workmanship associated with the works will generate settlements (downward movement). 7 | 10 Substructure strategy and sequence: The construction of the new basement and foundations for the concrete frame of the new development is envisaged to be carried out in a conventional bottom up sequence. However there are some activities that need to be undertaken in advance of both the demolition and the main works for the substructure and these are considered in more detail below. An enabling works contract has l been progressed before the main contract to undertake traditional underpinning to the party walls under both Beaufort Gardens and Beauchamp Place. It is now intended to undertake a second phase of underpinning to the underside of the existing front façade of the building as there will no longer be a requirement to excavate and form a basement under the façade and under the existing pavement vaults. This underpinning will be installed in short lengths and in two vertical staggered sections to provide a 5m deep level basement. The underpins will be in reinforced concrete cast with toe sections to assist the lateral stability. Temporary works propping will be retained in position throughout the underpinning works and following demolition of the building, the basement construction will include building watertight 200mm thick RC lining walls against the underpin faces, separated by a waterproof membrane. Shallow underpinning to the pavement vaults is not included in the enabling works because it is an activity which has difficult access and is close to not only the potential facade support works but also other essential foundation works required. It therefore needs to be carefully sequenced with the adjacent works. The façade retention has been installed and is an internal support structure. Demolition of the existing building down to existing lower ground floor level has been completed. As noted above, the first phase of underpinning, façade retention and demolition have been undertaken as part of an enabling works contract. The underpin operation is traditional but unusual in that it is a double level underpin. This can still be excavated manually and to depths regarded as manageably safe in order to achieve the required excavation depth of 5.5m below existing lower ground floor. A number of underpins however, have been left unconstructed until the building has been demolished, for reasons of safety where heavily loaded internal walls join with these party walls. These additional pins are to be completed as part of a second phase of enabling works following the demolition works. It is anticipated that all piles will be cast to the reduced piling platform level at lower ground floor and subsequently cut down to the new lower basement level once the basement excavations are complete. In this respect the contractor may consider using a softer concrete mix for the upper parts of the mini piles to make this operation easier. The design of the new foundations generally requires the piles to be capable of carrying a minimum load of 500kN. This can be achieved with 450mm diameter piles founding 18m below the existing lower ground floor level based on the test results of the soil investigation. Excavation to the reduced levels for the new basement can follow on from the demolition of the building, exposing all the piles. Pile concrete will be broken out down to the pile cut off level. The reinforcement cages for the structural section of the piles will be turned into the new pile caps. With the basement excavated and the piles cut back, the pile caps and core raft can be constructed followed by the new reinforced concrete columns and walls of the central core up to lower ground level. Whilst the new basement slab can be constructed at this stage, the construction of the lower ground floor slab in advance of the basement slab is suggested which will allow the removal of temporary propping/diaphragm support to the top of the underpinning walls. The new basement slab construction is expected to be cast in one operation directly over the column pile caps and over the perimeter underpinning toes and cast against the underpin wall. This slab will incorporate a kicker for the new perimeter retaining wall to be cast against the underpin wall connecting to the lower ground slab above with a dowelled connection. Alternatively retaining wall starter could be incorporated in the construction of the lower ground slab. Project number: 24710685 Dated: 31/07/2015 Revised: 8 | 10 Superstructure sequence The construction above ground is assume to follow a traditional approach of floor, walls and columns in a bottom up sequence from ground to roof level, noting the following: Stability: There are two stability cores that are located centrally within the building, the stair and lift cores. These cores will be in reinforced concrete and provide the lateral stability system for the building in combination with the rigid concrete floor diaphragms. They resist the wind forces on the building by cantilevering vertically from the basement raft. Floor Slabs: The ground floor to roof slabs is generally 225mm thick insitu R.C. flat slabs spanning between core walls and columns. At lower ground and first floors there are external terraces where the slab thickness is reduced to 150mm. Major slab openings for internal stairs will be trimmed using steel beams and columns. Column Layout: Generally all of the superstructure columns are 225mm thick R.C. blade columns to sit within new wall locations. At third floor, to manage a step in the rear elevation of the building, the columns are to ‘walk’ 1000mm. This requires a full storey of 1400mm long columns to aid in the transfer of the load vertically down the column. Roof Level: The roof area is split between areas of plant and areas of maintenance access only. The plant strip as well as the roof perimeter is supported by R.C. upstand beams spanning between existing columns below. Between 5th floor and roof level, above the 5th floor terrace, there is a new inclined steel supported mansard. The lightweight steel frame will sit on the slab edge at 5 th floor and connect into the edge upstand beam at roof level. Façade Retention: The front façade will be permanently supported by a new concrete and steel frame at lower ground floor level as described above. At the upper slab levels of the building the façade will be connected back to the new slab and columns using angle cleats which will provide restraint to the façade without transferring any load. 9 | 10 WSP UK Limited WSP House 70 Chancery Lane WC2A 1AF UK Tel: +44 (0)20 7314 5000 Fax: +44 (0)20 7314 5001 www.wspgroup.co.uk