Overland HS Crystallization Final Report

advertisement

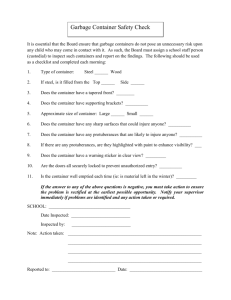

TITLE The Effects of Container Shape and Surface Tension on Crystallization in the Microgravity Environment FLIGHT DATE April 9, 2013 PRINCIPAL INVESTIGATOR: John Frost Ph.D., Overland High School, Cherry Creek School District, Aurora, CO CO-INVESTIGATORS: Abiy Alemayehu Aldair Cid-Gonzalez Janet Dominguez Jacob Donohoue Geffen Ferszt Jennifer Nass-Fukai Ph.D. Debra Gregg PE Jericho Oviedo Roberto Rodriguez Cynthia Turcios Ameen Sassi GOAL: The goal of this experiment is to determine if container shape and surface tension play a significant role on crystallization in a microgravity environment. OBJECTIVES: The objective of this work is to determine if container shape and surface tension play a role on crystallization in the microgravity environment. Understanding these effects on crystal growth is important because of the pharmaceutical applications associated with biological crystal growth. An important step in developing a new pharmaceutical drug is to develop a very thorough understanding of the active site the proposed drug would act upon. While the molecular structure and function of many binding sites in the human body are well understood, the exact 3-dimensional shape (often referred to as tertiary structure) of many of these binding sites is not available. Computer simulations can provide a great deal of insight, but the only way to truly understand the tertiary structure is to observe it through a process known as X-ray diffraction. This process uses x-rays and a single crystal of the molecule in question to produce a diffraction pattern which, through a complicated series of equations can be used to determine the exact 3dimensional structure of the molecule. Because this process relies on the diffraction pattern created by a crystal, the purity and perfection of the crystal plays an important role in the quality of the structure produced. Crystal growth of biological molecules can be very challenging which has caused scientists to investigate numerous ways to improve the process. One very successful improvement in the process of growing biological crystals was to conduct the process in space. Because the microgravity environment removes such complicating factors as density, convection, etc. which can cause imperfections in the crystal, diffusion becomes the driving force in crystal growth. Diffusion is a relatively slow and very low energy process which allows crystals to be grown in microgravity that are larger and which contain fewer imperfections than those grown on earth. Growing biological crystals in space has proven to be so successful that a number of different experimental packages developed solely for growing crystals in space have been deployed on the Space Shuttle, as well as the Mir and International Space Stations. ISS has been used extensively to grow some of the best examples of certain biological crystals ever produced, however there may still be room to improve this process. It is well known that surface tension is the dominant force acting upon liquids in a microgravity environment and shape, which affects surface tension, therefore plays a large role on the position of the liquid inside a container. Furthermore, it is also known that in the one-G environment, container shape plays a role in the macro-scale growth of crystals. Flat containers (such as petri dishes) are known to provide a higher potential for success when attempting to grow flat crystals, and round crystals containers are known to be better for producing rounded crystals. However, this knowledge seems to be limited to the results rather than a true understanding based upon documented experimentation. To the best of our knowledge, no one has formally studied the effects of container shape and surface tension on the crystallization process on earth, or in microgravity. Using a series of differently shaped acrylic containers filled with a super saturated solution of sodium acetate, we intend to study the effects of container shape on the crystallization process in the microgravity environment. By initiating crystallization during the microgravity portions of the flight and comparing the resulting crystals to those formed in identical containers grown in a 1-G environment we hope to formally determine if container shape does indeed play a role in the formation of crystals. METHODS AND MATERIALS: 2 Part Acrylic Christmas Ornaments, various shapes Super Saturated Sodium Acetate Solution Clear PVC Cement Blunt-tip Push-Pins 26 Guage Blunt-tip Needles Hot Glue Cotton String Foam Padding NASA’s Green No-Residue Tape, various sizes Glass Beakers – Various Sizes Hot Plate Glass Wool Vernier Temperature Pro 1 mL polypropylene syringe Vernier 3-Axis Accelerometer Vernier Global Positioning System Vernier Radiation Monitor Drill Scoopula Water Optical Microscope Hook and Loop Fastener, Sticky Backed PROCEDURE: The acrylic containers were prepared by drilling a 0.125” hole through the side in such a way that provided the best opportunity for all the air to be forced out of the container by the solution. The containers were then cleaned by blowing any particles left from the drilling process out with air. The two halves were then sealed using PVC cement, which chemically welded the halves together, and were allowed to dry as seen in Figure 1. Next, we prepared a super saturated solution of sodium acetate by dissolving 147 g of anhydrous sodium acetate in 100 mL of 100º C water. The still warm super saturated solution was then drawn up into 1 mL polypropylene syringes and injected into the acrylic containers. Hot glue was used to seal the filling hole in the container and a blunted push-pin was tied with a length of string to each container. The prepared containers were then allowed to cool and secured in a closed cell foam block which was attached to the bottom of the glove box using hook and loop fasteners. During the flights, the containers were taken out of the foam blocks and crystallization was initialized during the micro-gravity portion of the flight maneuver by forcing the blunt-tipped pin through the hot glue seal. The control group containers were crystalized in an identical fashion in the laboratory. Figure 1. Acrylic Containers ready to be filled with super saturated solution of sodium acetate. RESULTS: A number of differences were observed, both between the different shapes, and between the experimental and control groups. These differences are summarized below. ● Differences in amount of air bubbles ○ In the oval container, there were more and smaller bubbles in the experimental container ○ ○ ○ when compared with the control. In both the experimental and the control group of the sphere container there were few if any bubbles found. In both the experimental and the control group of the cylinder container there were few bubbles found. There was about the same amount of bubbles in both groups. In both the experimental and the control group of the star container there were few bubbles found. There was about the same amount of bubbles in both groups. ● Differences in thickness ○ In the oval container of the experimental group, there were thicker crystals and on the ○ ○ ○ control oval there were thinner crystals. In the sphere container of the experimental group, there were thin crystals and in the control group, the crystals were amorphous. In the cylinder container of the experimental group, there were thin crystals while the control group had thicker crystals. In the star container of the experimental group, there were straw-like crystals. In the control group of the star container, the crystals were amorphous. ● Differences in lengths ○ There were tall crystals found in the oval container of the experimental group and smaller crystals were found in the oval control group. ○ In the sphere container of the experimental group, there were tall crystals and in the control group, the crystals were amorphous. ○ In the cylinder container of the experimental group, there were tall straw like crystals and in the controlled group there were thicker crystals. ○ In the star container of the experimental group, there were long crystals stretching from the corner of the container the pointy tip of the container. In the control group of the star container, there were small and thick crystals that were oriented at random. ● Differences in lengths between fractures ○ In the experimental part of the oval container, the crystals were fractured at the curve of the oval and some fractured crystals at the edges of container. ○ In both experimental and control group, the crystals were fractured, some more frequently and distinctly than others. Based on the curvature of most of the ornaments, fractures occurred as the crystals grew, they bounced off the surfaces of the container at an angle and kept growing. ○ In the experimental part of the cylinder container, there were very few fractured crystals at the flat surface of the container and at the curvature of the cylinder, there were a lot of fractured crystals and longer distance between fractures. In the control group of the cylinder container, there were more fractures found in the same place but the length between fractures was much smaller than the experimental containers. ○ In the experimental group of the star container, there were fractures along the curve and the edge of the container. In the control group of the star container, there were fractures at the same place but with smaller length between the fractures. ● Differences between orientations ○ The orientation of experimental group is similar with all the containers. They start from the initial point with straw like crystals and grow in every direction until the crystals hit a curve or the corner of the container. In the curved containers the crystal fractured and formed smaller and smaller crystals. This went on all around the curve of all the containers. For the star container of the experimental group, the crystals grew towards the midpoint of the star. A representative photograph of the experimental and control groups are shown below. Figure 2. Representative images of the experimental (left) and control (right) group ovals. Figure 3. Representative images of the experimental (left) and control (right) group spheres. Figure 4. Representative images of the experimental (left) and control (right) group cylinders. Figure 5. Representative images of the experimental (left) and control (right) group stars. DISCUSSION: The results obtained with this work confirm what has been known for some time, that the microgravity environment affects the crystallization process in clearly observable ways. The effects of surface tension on the crystallization process however are less clear. The complexity of the experiment introduced a number of variables which we were unable to address this year but which may have had an effect on the results we observed. These ranged from variability in the degree of super saturation in the crystallization solution to the variability in the effects of the surface tension on the crystallization close to the inner surface of the container compared to that in the bulk solution. The relatively simple task of preparing a super saturated solution of sodium acetate proved to be much more difficult when used in this application. A super saturated solution of sodium acetate is incredibly unstable and nucleation can occur with the slightest disturbance. Furthermore, the process of filling the containers was relatively slow and we now suspect that during the time that some containers were being filled, evaporation of water from the hot solution caused a distribution in the extent of super saturation of the solution from container to container. This posed a huge challenge as filled containers cooled and oversaturated samples filled later in the process spontaneously crystallized. When this occurred we were forced to dissolve the crystals, clean the containers, and try again. This introduced yet another variable as some containers were out of necessity filled with a different batch of sodium acetate solution than the containers which did not spontaneously crystallize. Container shapes were chosen based on the known relationship between the geometry of an angle/edge and the surface tension exercised on a liquid in contact with that surface edge. A star shape was chosen for its acute angles, while an oval, sphere, and cylinder where chosen for their various degrees of curvature. Obviously with the exception of the sphere, the angles present are variable and in some cases quite different, the gentle curve of the circular portion of the cylinder compared to the 90 degree edge at the top and bottom, for example. While we failed to account for this, future work will attempt to address this with more specificity, perhaps by eliminating the oval and cylinders and replacing them with different sized spheres and cubes. As mentioned earlier, while the results of this year’s flight were inconclusive, they did provide hints and insights into the effects of surface tension on crystallization and how we might best study it. Future work will focus on limiting the number of confounding variables, reducing the size and number of parts, and reducing the amount of time needed to conduct the experiment in preparation for incorporating this work into a NanoRack to be flown on the ISS. We also intend to forge a relationship with a local university to have our results analyzed using an X-ray diffraction instrument. This would be an extremely valuable resource which would allow us to investigate the atomic scale results in addition to the macro-scale effects of surface tension on crystallization. It would also make it easier to obtain numerical, rather than subjective data. In addition, while we intend to continue using sodium acetate to investigate this relationship, we eventually hope to utilize a molecule more closely related to the biological molecules which require these types of advanced crystal growth techniques and which have the most significance to the development of new pharmaceuticals. CONCLUSION: This work confirmed the substantial effects on crystallization that microgravity plays and confirmed the suitability of our small molecule in the development of this work. The effects of container shape and surface tension on crystallization were inconclusive due to a large number of confounding variables, only some of which can be addressed on earth, but the results did yield hints that there is indeed a relationship. Future work promises to reduce many of the confounding variables, decrease the size, and increase the quantitative data obtained. ACKNOWLEDGEMENTS: We would like to thank the following individuals for their support: The National Aeronautics and Space Administration NASA Offices of Research Integration, Education, Reduced Gravity Education Flight Program and Reduced Gravity Overland High School and Cherry Creek School District Thermo Fischer Scientific The Rotary Club of Aurora-Fitzsimons The American Chemical Society The Nass-Fukai Family Artistic Apparel Kevin Brown REFERENCES: Lide, David R. CRC Handbook of Chemistry and Physics: A Ready-reference Book of Chemical and Physical Data. Boca Raton, FL: CRC, 1994. Print. Mark Milton Weislogel, PhD, 26 April 2013 “The Capillary Flow Experiments: Handheld Fluid Experiments for International Space Station” National Aeronautics and Space Administration. http://www.nasa.gov/mission_pages/station/research/experiments/978.html Richard J. Staples, July 2010. “Growing and Mounting Crystals Your Instrument will Treasure". Michigan State University Department of Chemistry and Chemical Biology. http://www2.chemistry.msu.edu/facilities/crystallography/staples.html Pasquale Di Palermo, July 2001. “Advanced Protein Crystallization Facility (APCF) Fact Sheet”. European Space Agency, National Aeronautics and Space Administration. www.nasa.gov/centers/marshall/news/background/facts/apcf.html CONTACT INFORMATION: John Frost PhD Thermo Fisher Scientific, NMR Technology Group 5445 Conestoga Ct. Suite 202 Boulder, CO 80012 303-802-6305 John.Frost@ThermoFisher.com Jennifer Nass-Fukai PhD Overland High School, Cherry Creek School District Science Department Head 720-727-3844 jnass-fukai@cherrycreekschools.org