Attachment G Technical Specifications Bridge Installation

Catherine Creek, CC44, Parcel 3 Construction

Culvert Replacement Project

CONFEDERATED TRIBES OF THE UMATILLA INDIAN

RESERVATION

Bridge Installation Technical Specifications

UNION COUNTY, OREGON

SECTION 31 03 33

REMOVAL OF WATER FROM EXCAVATION

PART 1 GENERAL

1.01

MEASUREMENT AND PAYMENT

A.

Cost: Include in applicable prices offered in the Price Schedule for items of work requiring removal of water from excavations.

1.02

DEFINITIONS

A.

Dewatering: Removal and control of groundwater from pores or other open spaces in soil or rock formations to allow construction activities to proceed as intended, and includes relief of groundwater pressure.

B.

Unwatering: Control and removal of ponded, seeping, or flowing surface water or emerging subsurface water from excavated surfaces and from precipitation within and adjacent to excavations and construction zones using channels, ditches, gravel drains, grave blankets, pipe, sumps, and discharge lines. Includes control and discharge of effluent waters.

1.03

SYSTEM DESCRIPTION

A.

Design, install, operate, maintain, and monitor water removal facilities.

B.

Design and layout facilities to collect discharge water from water removal systems and convey water to designated approved discharge points.

C.

Locate water removal facilities to maximize water removal and minimize construction interference.

D.

Select pump types and design discharge systems and settling ponds.

E.

Provide required equipment and monitor as required by permit.

SECTION 31 03 33, REMOVAL OF WATER FROM EXCAVATION Page 1

1.04

SUBMITTALS

A.

Submit in accordance with Section 01 33 00 - Submittals.

B.

RSN 31 03 33-1, Removal of water plan:

1.

Showing proposed method for removal of water from foundations.

2.

The plan may be placed in operation upon approval, but nothing in this paragraph shall relieve the Contractor from full responsibility for the adequacy of the water removal installation.

1.05

REGULATORY REQUIREMENTS

A.

Obtain required Federal, State, and local permits for water discharge and other activities associated with removal and control of water.

B.

Refer to Water Pollution Control sections of Technical Specifications for RM 44 Restoration

Project Phase III – Parcel 3 .

1.06

PROJECT CONDITIONS

A.

Conditions which may influence the unwatering include:

1.

Frequency and rate of precipitation at the site.

2.

Subsurface conditions including natural layering, thickness, permeability, and storativity of materials, and groundwater levels.

3.

Efficiency of pumps, collectors, and discharge systems.

B.

Water content and water levels in subsurface materials vary with location, depth, and material.

PART 2 PRODUCTS

Not Used

PART 3 EXECUTION

3.01

REMOVAL OF WATER

A.

Provide, maintain, and operate necessary facilities for removal of water from various parts of the work and for maintaining foundations and other parts of the work free from water as required for constructing each part.

B.

Where excavation for pipe trenches and excavation for structures extends below ground-water level, dewater the portion below the water level in advance of excavation.

SECTION 31 03 33, REMOVAL OF WATER FROM EXCAVATION Page 2

1.02

DE-WATERING

A.

Use ditches or sumps to lower and control water levels in advance of excavation.

B.

Construct ditches and sumps to collect seepage and runoff in work areas. Use sandbags, sand and gravel filter bedding, and other materials and techniques to control localized seepage.

1.03

UNWATERING

A.

Accomplish dewatering by use of sufficient number of properly screened wells or other equivalent methods.

B.

Dewater to prevent loss of fines from the foundation, maintain stability of excavated slopes and bottom of excavations, and to result in construction operations being performed in the dry.

END OF SECTION

SECTION 31 03 33, REMOVAL OF WATER FROM EXCAVATION Page 3

PART 1 SECTION 31 23 11

PART 2 EARTHWORK

A.

GENERAL

PAYMENT

Earthwork:

Payment: Lump sum price offered in the Price Schedule.

Includes:

Pumping and dewatering; work necessary to maintain excavations in good order during construction; removing such temporary construction, where required.

Excavating to the lines and grades shown on the drawings in order to shape channel and install foundation base and bridge footers.

Placing excavated material as fill to construct road subgrade.

Placing excavated material as fill to shape channel.

Backfilling the bridge footers.

Disposing of excess or unsuitable material generated during excavation.

Does not include:

Furnishing and installing riprap

Furnishing and installing streambed gravel

Furnishing and installing drain rock

Furnishing and installing gravel surfacing

DEFINITIONS

Jumping jack: 2 horsepower vibratory rammer. Gasoline powered. Wacker Model numbers BS

50, BS 60, BS 70, or equal

Plate compactor: 3 to 8 horsepower vibratory plate compactors. Gasoline powered. Wacker model WP 1550, or equal.

B.

PRODUCTS

DRAIN ROCK

In accordance with Section 34 71 20 – Modular Steel Bridge.

SECTION 31 23 11, EARTHWORK Page 1

EXCAVATED MATERIALS

The Contractor's operations in excavations shall be such that excavations will yield as much suitable material for use in permanent construction required under these specifications as practicable.

Place excavated materials which are too wet for immediate compaction temporarily in stockpiles until moisture content is reduced sufficiently to permit them to be placed in embankments.

CLEAN FILL

Obtain clean fill material from required excavations. If sufficient suitable material is not available from this source, obtain additional material from commercial sources.

The Government makes no guarantee that material meeting the requirement for clean fill is contained in or can be processed from materials excavated.

Free of roots, stumps, limbs, vegetation, organic matter, ice, construction debris, scrap materials, refuse, man-made wastes, or chemical or hydro-carbon compounds.

MATERIAL FOR BACKFILL

Type and amount of material used for backfill, and manner of depositing material shall be subject to approval.

Obtain backfill material from required excavations. If sufficient suitable material is not available from this source, obtain additional material from commercial sources.

The Government makes no guarantee that specified backfill materials are contained in or can be processed from materials excavated.

Free of roots, stumps, limbs, vegetation, organic matter, ice, construction debris, scrap materials, refuse, man-made wastes, or chemical or hydro-carbon compounds.

Backfill material shall contain no stones larger than 3 inches in diameter.

C.

EXECUTION

EXCAVATION, GENERAL

Excavate structure foundations to elevations shown on the drawings or established by the COR.

The Government reserves the right, during progress of work, to vary slopes, grades, and dimensions of excavations from those specified.

The Government does not represent that excavation performed under these specifications can be made to or maintained at paylines shown on the drawings or described in these specifications.

Perform excavation in the dry.

SECTION 31 23 11, EARTHWORK Page 2

Do not excavate in frozen materials without written approval.

Where excavating in backfill and embankment placed under these specifications, excavate in accordance with applicable provisions for excavation.

Blasting: Not allowed.

Preserve material below and beyond established lines of excavation in the soundest possible condition.

Damage to work due to the Contractor's operations shall be repaired by and at the expense of the

Contractor.

Material beyond required or prescribed excavation lines which is loosened by the Contractor's operations shall be removed at the expense of the Contractor.

PREPARATION OF STRUCTURE FOUNDATIONS

Prepare foundations at structure sites by methods which will provide firm foundations for structures.

Finish bottom and side slopes of excavation, upon or against which the structure is to be placed, to prescribed dimensions.

Moisten and compact prepared surfaces with suitable tools to form firm foundations upon or against which to place the structure.

Where unsuitable material is encountered in the foundation for a structure, the COR will direct performance of additional excavation to remove unsuitable material.

Refill additional excavation with drain rock.

OVEREXCAVATION

If foundation material is excavated beyond lines required to receive the structure, fill over excavation with drain rock.

If foundation material is disturbed or loosened during excavation or otherwise, remove and replace it with drain rock.

DISPOSAL OF EXCAVATED MATERIALS

Dispose of excavated materials which are unsuitable for or are in excess of embankment, backfill, or other earthwork requirements, as determined by the COR, at approved disposal source in accordance with local regulations off of the site.

PLACING CLEAN FILL

Place clean fill to the lines and grades shown on the drawings.

Maximum lift thickness: 8 inches.

SECTION 31 23 11, EARTHWORK Page 3

Compact each lift with minimum 12 passes of rubber-tired equipment until top of lift is smooth, firm, and stable.

PLACING BACKFILL

Place backfill within 2 feet of bridge footers and ecology blocks, or as directed by the COR.

Place backfill carefully and spread in uniform layers so that all spaces about rocks and clods will be filled.

Maximum lift thickness: 4 inches

Compact each lift with repeated passes of jumping jack or plate compactor until top of lift is smooth, firm, and stable.

END OF SECTION

SECTION 31 23 11, EARTHWORK Page 4

PART 3 SECTION 31 32 32

PART 4 GEOTEXTILE

A.

GENERAL

MEASUREMENT AND PAYMENT

Geotextile:

Measurement: Surface area required to be covered, except no allowance will be made for seam overlap, repairs, or waste.

Payment: Square yard price offered in the schedule.

REFERENCE STANDARDS

ASTM International (ASTM)

ASTM D4355-07

ASTM D4491-99a(2009)

ASTM D4533-11

ASTM D4632-08

ASTM D4751-12

ASTM D5261-10

ASTM D6241-04(2009)

Deterioration of Geotextiles by Exposure to

Light, Moisture, and Heat in a Xenon-Arc

Type Apparatus

Water Permeability of Geotextiles by

Permittivity

Trapezoid Tearing Strength of Geotextiles

Grab Breaking Load and Elongation of

Geotextiles

Determining Apparent Opening Size of a

Geotextile

Measuring Mass per Unit Area of

Geotextiles

Static Puncture Strength of Geotextiles and

Geotextile-Related Products Using a 50-mm

Probe

SUBMITTALS

Submit the following in accordance with Section 01 33 00 - Submittals

RSN 31 32 32-1, Manufacturer's certification:

Geotextile furnished meets specified chemical, physical, and manufacturing requirements.

Sewn seams, if used:

SECTION 31 32 32, GEOTEXTILE Page 1

Certification stating that polymeric threads to be used for sewing have chemical resistance properties equal to or exceeding those of geotextile.

Include data showing that sewn seams have tensile strength of not less than specified percent of parent geotextile material.

DELIVERY, STORAGE, AND HANDLING

Wrap geotextile rolls in relatively impermeable and opaque protective covers.

Mark or tag geotextile rolls with manufacturer's name, product identification, lot number, roll number, and roll dimensions.

Mark geomembrane with special handling requirements such as "This Side Up" or "This Side

Against Soil to be Retained."

Protect geotextile from ultraviolet light exposure, temperatures greater than 140 degrees F

(60 degrees C), precipitation or other inundation, mud, dirt, dust, puncture, cutting, or other damaging or deleterious conditions.

Elevate and cover material stored outside with waterproof membrane.

B.

PRODUCTS

GEOTEXTILES

Needle-punched, nonwoven geotextile comprised of long-chain polymeric filaments composed of at least 85 percent, by weight, polyolefins or polyesters.

Orient filaments into stable network which retains its structure during handling, placement, and long-term service.

Stabilizers or inhibitors added to filament base material: Resist deterioration due to ultraviolet or heat exposure.

Geotextile edges: Selvaged or otherwise finished to prevent outer material from pulling away.

Conform to roll values listed in Table 31 32 32B - Geotextile Physical Properties.

Values listed are minimum average roll values (MARV = s), unless otherwise noted.

Test results for weaker principal direction shall meet or exceed minimum values listed in the table.

Mass per unit area is a nominal value and is provided for information purposes only.

Direct exposure to sunlight: Withstand 14 days with no measurable deterioration.

SECTION 31 32 32, GEOTEXTILE Page 2

PINS

Mass per unit area, nominal

Grab tensile

Elongation at break

Trapezoidal tear

Puncture strength

Permittivity

Table 31 32 32A. - Geotextile Physical Properties

Property Test Method

Apparent opening size (minimum US Sieve

No. / maximum opening size)

UV resistance – tensile strength retained at

500 hours, minimum

ASTM D5261

ASTM D4632

ASTM D4632

ASTM D4533

ASTM D6241

ASTM D4491

ASTM D4751

ASTM D4355

Required Values

8 oz/yd

2

200 lbs

50 percent

70 lbs

440 lbs

1.0 sec

-1

70 US Sieve

70 percent

Pins: 3/16-inch diameter, 18-inches long steel pins, pointed at one end, and fitted with 1-1/2 inch diameter washer at other end.

FOUNDATION BASE

In accordance with Section 34 71 20 – Modular Steel Bridge.

C.

EXECUTION

SUBGRADE PREPARATION

Prepare surface upon which geotextile is to be placed to a firm surface, reasonably even and smooth, and free of offsets, abrupt indentations, and protruding materials greater than 1-1/2 inches.

Fill low spots with foundation base.

Obtain COR approval of subgrade before installing geotextile.

INSTALLATION

Place geotextile in the manner and at locations shown on drawings.

Lay geotextile smoothly, free of tension, stress, folds, wrinkles, or creases so far as is practical and except where required in these specifications.

SECTION 31 32 32, GEOTEXTILE Page 3

Shingle overlaps on slopes with upstream roll placed over downstream roll.

Pin, staple, or weight to hold geotextile in position. Anchor terminal ends of geotextile with key trenches or aprons at crest and toe of slopes.

In the presence of wind, weight geotextiles with sandbags or equivalent until cover material placed.

Do not entrap stones, soil, excessive dust, or moisture in geotextile that could damage geotextile or hamper subsequent seaming.

Do not drive or operate equipment directly on geotextile.

SEAMING

Join adjacent sheets of geotextile by overlapping or sewing.

Overlapped seams:

Overlap minimum: 24 inches.

Upstream/upslope roll placed over the downstream/downslope roll.

Weight or pin on 3-foot centers to secure the overlap during placement of cover material.

Do not use pins when installed over geomembrane.

Sewn seams:

Interlocking or sewn twice.

Thread:

Contrasting color.

Chemical resistance: Equal to geotextile.

Sew geotextiles continuously. Spot sewing is not allowed.

Sewn seam strength: Not less than 70 percent of parent material strength.

RIPRAP INSTALLATION

Place riprap or backfill material so as not to damage geotextile.

Before placing riprap, demonstrate that placing technique will not damage geotextile or underlying geomembrane. If the demonstration does not show that riprap can be installed without damaging geotextile, modify riprap placing technique (such as reducing drop height, installing additional layer of sacrificial geotextile, or installing additional gravel cushion).

Begin riprap placement at toe and proceed up slope.

SECTION 31 32 32, GEOTEXTILE Page 4

REPAIRS

At placement, geotextile will be rejected if it has defects, rips, holes, flaws, deterioration, contamination, or damage.

Replace or repair geotextile damaged during installation or placement of cover in the following manner:

Remove cover from damaged area of geotextile.

Remove any soil or other material which may have penetrated torn geotextile.

Repair damaged geotextile by placing additional layer of geotextile to cover damaged area and either sew the patch to undamaged geotextile according to sewing requirements stated above or overlap undamaged geotextile by at least 3 feet on all sides.

CONTRACTOR FIELD QUALITY EXAMINATION

After installation, examine entire geotextile surface to ensure that potentially harmful foreign objects (such as needles) are not present.

Remove foreign objects or replace geotextile.

END OF SECTION

SECTION 31 32 32, GEOTEXTILE Page 5

This page intentionally left blank.

SECTION 31 32 32, GEOTEXTILE Page 6

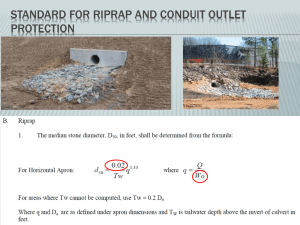

SECTION 31 37 00

RIPRAP

GENERAL

A.

MEASUREMENT AND PAYMENT

Riprap:

Measurement:

Weight of material placed.

Weigh materials at state certified scale.

Payment: Ton price offered in schedule.

B.

REFERENCE STANDARDS

ASTM International (ASTM)

ASTM C 88-05

ASTM C 97-02(2008)

Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate

Absorption and Bulk Specific Gravity of Dimension

Stone

Oregon Department of Transportation (ODOT)

ODOT Specifications Oregon Standard Specifications for Construction,

2015

ODOT Test Methods

ODOT TM 208

ODOT TM 206

Laboratory Manual of Test Procedures, 2015

Oregon Air Aggregate Degradation

Soundness of Aggregate by Use of Sodium Sulfate

C.

DEFINITIONS

Unsuitable material: soft, unstable soil and other portions of the soil that cannot be compacted satisfactorily, as determined by COR.

PRODUCTS

D.

ROCK

Hard, dense, and durable.

Specific gravity, ASTM C 97, minimum: 2.55.

SECTION 31 37 00, RIPRAP Page 1

Absorption, ASTM C 97, maximum: 6 percent.

Loss, Sulfate Soundness, ASTM C 88:

Average loss of 2-1/2-inch to 1-1/2-inch and 1-1/2” to ¾-inch fraction after 5 alternations: 16 percent maximum

Degradation, ODOT TM 208

Passing No. 20 Sieve: 35 percent, maximum.

Sediment height: 8 inch, maximum.

Either quarried rock or boulders may be used for riprap.

Shape:

Predominantly angular.

Maximum dimension not greater than 3 times minimum dimension.

Rounded rock not acceptable.

Free from overburden, spoil, shale, and organic material. Non-durable rock, shale or rock with shale seams is not acceptable.

Riprap Gradation: Reasonably well graded within limits shown in Table 31 37 00A - Riprap

Gradation.

Table 31 37 00A - Riprap Gradation*

Weight of rock

(lbs)

200-140

140-80

80-8

8-0

Percent by weight

20

30

40

10 to 0

*Gradation matches requirements for Class 200 riprap per ODOT Specifications.

EXECUTION

E.

AREAS TO RECEIVE RIPRAP

Place riprap to the lines and grades shown on the drawings, or as directed by COR.

SECTION 31 37 00, RIPRAP Page 2

F.

PREPARATION

Remove brush, trees, stumps and other organic material from slopes to be protected by riprap and dress to a smooth surface.

Remove all unsuitable material to two foot depth below subgrade and replace with Foundation

Base meeting the requirements of Section 34 71 20 – Modular Steel Bridge

Prior to placing riprap, furnish and install Foundation Base and bridge footers. Work to install the Foundation Base and bridge footers shall be in accordance with Section 34 71 20 – Modular

Steel Bridge and the manufacturer’s instructions.

Furnish and install geotextile as shown on the drawings and in accordance with Section 31 32 32

– Geotextile.

Install the riprap prior to installing the bridge deck.

Removal of water in accordance with Section 31 03 33 – Removal of Water from Excavation is required during riprap installation in order to verify constructed subgrade meets the requirements of the plans.

G.

PLACING

Place rocks so that larger rocks are evenly distributed and small rock fragments fill the spaces.

Include rock spalls or gravel in an amount to fill voids in riprap, but not in excess of an amount to be determined by the COR.

Dump and smooth by moving rocks into position so that material when in place is stable.

Placing riprap on geotextile:

Drop height, maximum: 1-foot.

Before placing riprap, demonstrate that placing technique will not damage geotextile.

If the demonstration does not show that riprap can be installed without damaging flexible channel liner, modify riprap placing technique.

Possible modifications to placing technique include reducing drop height, installing layer of sacrificial geotextile, or installing gravel cushion.

Begin riprap placement at toe and proceed up slope.

Leave no unreasonably large unfilled spaces within riprap.

END OF SECTION

SECTION 31 37 00, RIPRAP Page 3

SECTION 32 15 10

GRAVEL SURFACING

GENERAL

A.

MEASUREMENT AND PAYMENT

Gravel Surfacing:

Measurement: Volume of in-place compacted material to outlines of area covered and to specified thickness.

Payment: Cubic yard price offered in the schedule.

B.

REFERENCE STANDARDS

ASTM International (ASTM)

ASTM D1241-07 Materials for Soil-Aggregate Subbase, Base, and Surface

Courses

PRODUCTS

C.

GRAVEL

Gravel: ASTM D1241, Type I, Gradation C, surface-course materials, except,

Fine aggregate:

Minimum passing No. 200 sieve: 8 Percent.

Fraction passing No. 40 sieve:

Liquid limit, maximum: 35.

Plasticity index range: 4 to 9.

EXECUTION

D.

PREPARATION

Grade and prepare subgrade free from depressions and soft spots.

Obtain COR approval of subgrade before placing surfacing.

E.

PLACING

Place gravel surfacing at following locations:

SECTION 32 15 20, STREAMBED GRAVEL Page 1

On prepared road subgrade to limits shown on drawings.

On bridge deck to nominal 6 inch thickness

Place, moisten, and compact gravel surfacing :

Moisten or aerate material as necessary to provide moisture content that will readily facilitate compaction. Add water by sprinkling just prior to compaction, as necessary.

Compact gravel by minimum twelve passes of tracked, heavy equipment until surface is firm and stable.

Dress finished surface.

Completed installation shall meet or exceed required thickness shown on drawings.

END OF SECTION

SECTION 32 15 20, STREAMBED GRAVEL Page 2

SECTION 32 15 20

STREAMBED GRAVEL

SECTION 32 15 20

STREAMBED GRAVEL

GENERAL

A.

MEASUREMENT AND PAYMENT

Streambed Gravel:

Measurement: Volume of in-place material to outlines of area covered and to specified thickness.

Payment: Cubic yard price offered in the schedule.

B.

REFERENCE STANDARDS

ASTM International (ASTM)

ASTM D3744-11

ASTM C 131-14

ASTM C 97-09

Standard Test Method for Aggregate Durability Index

Standard Test Method Resistance to Degradation of Small-

Size Coarse Aggregate by Abrasion and Impact in the Los

Angeles Machine

Standard Test Method for Absorption and Bulk Specific

Gravity of Dimension Stone

PRODUCTS

C.

STREAMBED GRAVEL

Aggregate: naturally occurring water rounded aggregates. Aggregates from quarries, ledge rock, and talus slopes are not acceptable.

Degradation factor, ASTM D 3744, 15 minimum.

Degradation, ASTM C 131, 50 percent maximum.

Specific gravity, ASTM C 97, 2.55 minimum.

Streambed gravel gradation: reasonably well graded within limits shown in Table 32 15 20A –

Streambed Gravel Gradation.

SECTION 32 15 20, STREAMBED GRAVEL Page 1

Table 32 15 20A – Streambed Gravel

Gradation

Percent Passing

D100

D85

D50

D16

D10

Size Class

12 inches

2 inches – 5 inches

0.5 inch – 3 inches

0.08 inches – 1 inch

<0.08 inch

EXECUTION

D.

PREPARATION

Install riprap in accordance with Section 31 37 00 - Riprap.

Obtain COR approval of riprap before placing streambed gravel.

E.

PLACING

Place streambed gravel at following locations:

Over riprap, to the lines and grades shown on the drawings.

To the thicknesses shown on the drawings.

END OF SECTION

SECTION 32 15 20, STREAMBED GRAVEL Page 2

SECTION 34 71 20

MODULAR STEEL BRIDGE

GENERAL

MEASUREMENT AND PAYMENT

Modular Steel Bridge:

Payment: Lump sum price offered in the schedule.

Includes:

Designing the bridge

Fabricating the bridge superstructure, deck, rails, bearing pads, anchor plates, and other components

Furnishing backwalls

Delivery to site

Off-loading at the site

Precast Footers:

Payment: Price per each offered in the schedule

Includes:

Strength design of the concrete footers

All materials, labor, and equipment necessary to construct the abutments

Delivery to site

Bridge Installation:

Payment: Lump sum price offered in the schedule

Includes:

Labor and equipment necessary to install the footers, bridge superstructure, bridge rails, and any other bridge components necessary for a full and complete installation, in accordance with manufacturer’s instructions.

Field welding

Field bolting

Furnishing and installing foundation base

Earthwork and excavation

SECTION 34 71 20, MODULAR STEEL BRIDGE Page 1

1.04

REFERENCE STANDARDS

American Association of State Highway and Transportation Officials (AASHTO)

LRFD Bridge Design Specifications, 2010

American Concrete Institute (ACI)

ACI 318-14

American Welding Society (AWS)

AWS D1.1/D1.1M-10

Building Code Requirements for Structural

Concrete

American Institute of Steel Construction (AISC)

AISC 360-10 Specifications for Structural Steel Buildings

Structural Welding Code - Steel

ASTM International (ASTM)

ASTM A 709

ASTM A 588

Standard Specification for Structural Steel for

Bridges

Standard Specification for High-Strength Low-

Alloy Structural Steel, up to 50 ksi [345 MPa]

Minimum Yield Point, with Atmospheric Corrosion

Resistance

SUBMITTALS

Submit the following in accordance with Section 01 33 00 - Submittals.

RSN 34 71 10-1, Certifications, for approval:

Manufacturer’s certification that modular steel bridge and precast footers meet specified requirements.

RSN 34 71 20-2, Preliminary Shop Drawings, for approval, including:

Plan view of bridge superstructure, including dimensions of all major components

Superstructure typical section, including dimensions from top deck to bottom chord.

Footer plan view

Footer section

RSN 34 71 20-3, Design Calculations, for approval:

Stamped by Design Engineer

RSN 34 71 20-4, Manufacturer’s Installation Instructions, for information.

RSN 34 71 20-5, Final Shop Drawings, for information.

SECTION 34 71 20, MODULAR STEEL BRIDGE Page 2

QUALIFICATIONS

Design Engineer: holding current professional engineer license in any state.

DELIVERY, STORAGE, AND HANDLING

Bridge and footers shall be delivered by the manufacturer(s) to the project site. Access is primarily paved roads.

Transport and handle in a manner which prevents damage.

PRODUCTS

FOUNDATION BASE

Commercially available washed, uncrushed aggregate, commonly referred to as drain rock, meeting the following gradation requirements:

Table 34 71 20A – Percent by Weight

Passing Square Mesh Size

Sieve size

3 inch

1 inch

3/8 inch

No. 200

Nominal maximum size

100

25 to 60

0 to 4

0 to 2

EXECUTION

BRIDGE DESIGN REQUIREMENTS

In accordance with AASHTO LRFD Bridge Design Specifications, 2010.

Design loading: HL93

Nominal out-to-out bridge length: 40 feet

Nominal bridge deck width: 14 feet

Structural members: ASTM A 588 weathering steel

Guardrail: Weathering steel guardrail system meeting TL-1

SECTION 34 71 20, MODULAR STEEL BRIDGE Page 3

FOOTER DESIGN REQUIREMENTS

In accordance with ACI 318.

Presumptive soil bearing capacity: 3000 psf.

INSTALLATION

Shape the channel subgrade to the lines shown on the drawings.

Prepare subgrade slopes for riprap, in accordance with Section 31 37 00 – Riprap.

Furnish and install foundation base to the lines and grades shown on the drawings.

Install the footers in accordance with manufacturer’s instructions. Check diagonal dimensions given in manufacturer’s plan set and adjust footers as necessary.

Check footers are level each way and with each other within 0.02’.

Furnish and install riprap between footers, per Section 31 37 00 – Riprap, prior to installing bridge deck.

Furnish and install streambed gravel over riprap, per Section 31 15 20 – Streambed Gravel, prior to installing bridge deck.

Install bridge deck, backwalls, guardrails per manufacturer’s instructions.

END OF SECTION

SECTION 34 71 20, MODULAR STEEL BRIDGE Page 4

SECTION 01 33 00A

LIST OF SUBMITTALS

* Submittal Types: A - Action, I - Information

** CO indicates Contracting Officer, CTUIR; BOR indicates BOR Design Engineer.

RSN

Clause or

Section

Title

Submittals required

Due date or delivery time

Type

*

Responsible code

No. of sets to be sent to: **

CO BOR

31 03 33-1 Removal of

Water From

Excavation

31 32 32-1 Geotextile

Removal of water plan

1 week prior to mobilization

34 71 10-1 Modular steel bridge

34 71 10-2 Modular steel bridge

34 71 10-3 Modular steel bridge

34 71 10-4 Modular steel bridge

34 71 10-5 Modular steel bridge

Manufacturer’s certification

Certifications

1 week prior to mobilization

2 weeks prior to fabricating bridge

2 weeks prior to fabricating bridge

Preliminary shop drawings

Design calculations 2 weeks prior to fabricating bridge

Manufacturer’s installation instructions

1 week prior to delivery

Final shop drawings 1 week prior to delivery

A

A

A

A

A

I

I

CO

CO

CO

CO

CO

CO

CO

1 1

1 1

1 1

1 1

1 1

1 1

1 1

SECTION 01-33-00A – LIST OF SUBMITTALS Page 1

BID SCHEDULE

Catherine Creek, CC44, Parcel 3 Construction

Culvert Replacement Project

CONFEDERATED TRIBES OF THE UMATILLA INDIAN RESERVATION

UNION COUNTY, OREGON

Bid

Item

No.

Reference

Section

Work or Material Quantity Unit Unit

Price

Amount

1 Mobilization/Demobilization

2 31 23 11 Earthwork

3 31 32 32 Geotextile

4 31 37 00 Riprap

5 32 15 10 Gravel surfacing

6 32 15 20 Streambed gravel

7 34 71 20 Modular Steel Bridge

8 34 71 20 Precast footers

9 34 71 20 Bridge Installation

1

1

150

100

40

20

1

1

1 l.s. l.s. s.y. ton c.y. c.y. l.s. l.s. l.s.

$

$

$

$

$

$

$

$

$

$

TOTAL FOR SCHEDULE $

Signature_______________________________

Taxpayer Id No._______________________________

Date__________________

NOTE: ALL OTHER EXCAVATION, BACKFILLING, ETC. SHALL BE SUBSIDIARY TO ONE OR MORE OF THE

PAY ITEMS ABOVE AND THERE IS NO ADDITIONAL COMPENSATION FOR THESE OPERATIONS.

$

$

$

$

$

$

$

$

SCHEDULE OF ITEMS AND PRICES Page 1