Role of standards in Promotion of Technical Textiles

advertisement

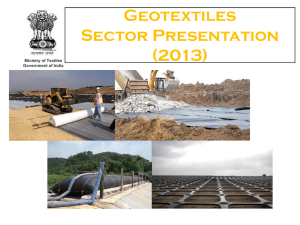

Role of standards in Promotion of Technical Textiles Presentation on Use of Geotextiles in highway sector On behalf of Indian Roads Congress By A.V.Sinha, Former DG(RD) & Spl Secretary, Ministry of Road Transport & Highways Geosynthetics and their varieties • Geotextiles – Synthetic fibres (Polypropylene, Polyester, Polyvinyl Chloride, Polyamide, or Polyethyleyne) converted into fabric by (a) weaving (woven), or (b) bonding of random fibres (non-woven), or (c) knitting – Good drainage property • Geogrids – Extruded sheets of Polypropylene and Polyethyelne punched to form a grid pattern having large apertures – Good strength properties • Geonets – Polymer strands crossing one another at an angle (usually acute angle to give a diamond pattern aperture) and bonded at joints by thermal bonding – Used in combination with Geotextile or Geomembrane for drainage – Not used for strength Geosynthetics and their varieties (..contd) • Geocomposites – A composite material of usually three out of geotextile, geogrid, geonet, and geomembrane in laminated or other form. – Good drainage property and used for Prefabricated Vertical Drain • Geomembranes – An impervious geosyntheitc material – Used for checking migration of water(e.g lining of drains/ canals) • Geomats – A three dimensional (as opposed to two dimensional geotextile and geogrid) open mat – Good drainage property, suitable for draining filling behind bridge abutment Geosynthetics and their varieties (..contd) • Geocells – These are formed by connecting HDPE strips in series to form a pattern of grid in three dimensions, the width of strips forming the walls of the cells which are filled with soil/gravel/stones etc – The confinement provided by cell walls gives strength – Improves the bearing capacity of weak foundations • Natural geotextiles – Naturally growing fibres (like jute) and their strands form these geotextiles – Usually biodegradable and used for slope protection by vegetation Areas of Application of Geo Synthetics and predominant properties • • • • Retaining Wall: Strength Embankment in soft soil: Strength, drainage Repairs of damaged Pavement: Strength Slope protection and Erosion Control: Separation, filtration, aperture size • Drainage of embankment, subgrade, fill behind abutment, and surface drains: Separation, filtration, drainage Standardization of Geotextile applications • Indian efforts: – 1994: Indian Roads Congress published a State-of-the-Art Report: Application of Geotextile in Highway Engineering (IRC:SP12) – 2001: Ministry of Road Transport and Highways included a chapter in its Specifications (MORTH Specficification for Roads and Bridges) – 2002:Indian Roads Congress published Guidelines for use of Geotextiles in Road Pavements and associated works – 2011: MORTH Specifications including chapter on Geptextile under revision – 2011: IRC Council approved for publication the State-0f-the-Art Report on use of Jute Geo textile (under print) – 2011: IRC Council approved for publication Guidelines for the Deesign and Construction of Geosynthetic reinforced embankment on soft soils Standardization of Geotextile applications (..contd) • International efforts – 1995/2010: British Standard BS 8006 Code of Practice for Strengthened/ Reinforced soils and other fills was published – 1998/2001: Federal Highway Administration of US published a document (Publication No. FHWANHI-00-43) on reinforced soils General Specifications for Geosynthetic Systems • Material properties: These are generally specified and accepted if the material tests are as per standard procedures specified by – – – – American Society for Testing of Materials (ASTM) International Standardization Organization (ISO) British Standards (BS) Accredited laboratories • Design: This required to be done as per BS or FHWA procedure • Certification: A certification by the system supplier about conformity with – ISO for manufacturing process – BBA (British Board of Agreement, AASHTO (American Association of State Highway and Officials) – Accredited laboratories • Warranty:Client seeks a warranty from the supplier – The warranty can be for as long as for 50 years Typical geotextile properties Property Requirement Unit Test Method Minimum Average Roll Value (MARV) at more than 50% elongation under different installation conditions Grab strength 500-900 Newton (N) ASTM D 4932 Tear Strength 180-350 N ASTM D 4533 Puncture strength 300-500 N ASTM D 6241 Burst strength 180-350 N ASTM D 3786 Ultraviolet Stability: Not less than 70 % of the above values after 500 hrs exposure Filtration and separation Apparent Opening Size (AOS) <0.3 mm ASTM D 4533 Permittivity > 0.5 per sec EN ISO 11058 Tensile strength (MD/CMD) >60/>45 kN/m ISO10319 Strain at max strength(MD/CMD) 30/20 % ISO10319 Reinforcement Indian Test Procedures • IS 13162 (part2): Test Method for deterioration of Geotextile for exposure to Ultraviolet Light and Water • IS 14324: Test methods for Water Permeability of Geotextile by Permittivity • IS 14294: Test Method for Detrming Apparent Opening Size for Geotextiles • IS 13162 (Part 4):Test Method for Index Puncture Resistance of Geotextiles and related products (Source : IRC SP 59:2002) Gaps in Design Procedures • Indian standards on Geotextiles are practically absent – One Guideline recently approved by IRC Council and will be released shortly • Design, particularly where strength is the main concern ( like retaining walls, embankment, pavement rehabiltation) is an involved process – Design Approach particularly for internal stability of structures (i.e where geotextiles come into play) has to be standardized Gaps in Design Procedures • Design (..contd) – Factors of safety, reduction factors, partial factors etc used in the British and US standards have to be evolved for our national codes and Guiodelines • Testing Standards – There is huge gap in the requirement and availability of national testing procedures – An indicative list of subjects on which test procedures need to be developed are as follows: Gaps in Design Procedures • Indicative list of tests – Determination of friction between the soil and geotextile reinforcement at different levels of strain – Determination of vulnerability of geotextiles to chemicals and microbiological substances present in soil and water – Detrmination of the effects of creep and long term stability – Determination of relationship between ultimate strength and design strength – Suggesting reduction factors (or partial factors or factors of safety on the basis of • • • • • • • Tests Manufacturing Process Serviceability conditions Installation factors Temperature variations Durabilty factors Construction imperfections Thank You for your attention