3a -Permeable Pavement Proposal_6.12.13

advertisement

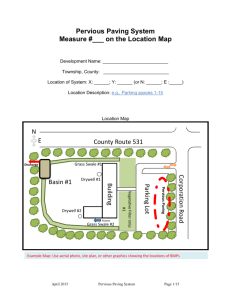

Permeable Pavement Proposal For NSCC Sustainability Office Permeable Pavement Overview Permeable pavement allows rain water and snow melt to infiltrate through it to be filtered and recharged into the ground as groundwater. Permeable pavement is asphalt or concrete mixed with fewer fine particles to create more air space which allows water to permeate through it. An underlying layer of fine sediment filters water and below it a bed of uniformgrade stones stores water as it infiltrates into the ground. Permeable pavement is ideal for use in parking lots, walkways and low-traffic roadways. Areas that are paved with traditional, non-permeable pavement are a significant source of polluted stormwater runoff. The use of permeable pavement can greatly decrease stormwater runoff. Benefits of Permeable Pavement Managing Runoff - Permeable paving surfaces mitigate stormwater or urban runoff which can cause significant erosion and siltation in surface water bodies. Controlling Pollutants – As water permeates through the porous pavement system and into the ground, pollutants are mainly captured within the paver system and the uppermost layers of underlying soil, which keeps the pollutants in place in the soil. Additionally, permeable pavement solutions allow water seepage to groundwater recharge while preventing the stream erosion problems. They capture the heavy metals that fall on them, preventing them from washing downstream and accumulating inadvertently in the environment. In the void spaces, naturally occurring micro-organisms digest car oils, leaving mostly nothing other than carbon dioxide and water. Rainwater infiltration is usually less than that of an impervious pavement with a separate stormwater management facility somewhere downstream. Trees - Permeable pavements may give urban trees the rooting space they need to grow to full size. A "structural-soil" pavement base combines structural aggregate with soil; a porous surface admits vital air and water to the rooting zone. This integrates healthy ecology and thriving cities, with the living tree canopy above, the city's traffic on the ground, and living tree roots below. The benefits of permeable on urban tree growth have not been conclusively demonstrated and many researchers have observed tree growth is not increased if construction practices compact materials before permeable pavements are installed. Reduction of Overall Irrigation Demand - By allowing the water to seep into the ground, the direct and surrounding areas will need much less man-produced irrigation. This will save you money and reduce the amount of water used for your everyday irrigation needs. 1 Local Heat Island Effects: By allowing water to filtrate into the ground, the surface and surrounding area temperatures will be cooler than a hard impervious surface. Bonus points for using permeable surfaces that are also light in color, because they will also help reflect sun and heat to even further reduce the local ambient temperature, which will also improve the health of local vegetation and improves air quality. Maintenance Needs and Frequency - Permeable pavement needs to be vacuum swept three to four times a year to prevent pores from becoming clogged and precluding infiltration. Maintenance Cost Example - Approximately $400 - $500/year for vacuum sweeping of a half-acre parking lot. Costs Several factors influence the overall cost of porous asphalt: Material availability and transport - The ease of obtaining construction materials and the time and distance for delivery. Site conditions - Accessibility by construction equipment, slope, and existing buildings and uses. Subgrade - Subgrade soils such as clay may result in additional base material needed for structural support or added stormwater storage volume. Stormwater management requirements - The level of control required for the volume, rate, or quality of stormwater discharges will impact the volume of treatment needed. Project size - Larger porous asphalt areas tend to have lower per square foot costs due to construction efficiencies. Costs vary with site activities and access, porous asphalt depth, drainage, curbing and under drains (if used), labor rates, contractor expertise, and competition. Data or studies that compare construction, maintenance, and life cycle costs for stormwater management systems are limited. The wide range of site conditions and design requirements also makes it difficult to determine the life cycle cost benefits. It is recommended that each potential application be evaluated on a site-by-site basis. However, a range of cost estimates for the basic installation of permeable paver materials is given in the table below for comparison purposes. The wide range of costs for the paver systems should be noted. 2 Permeable Pavement System Cost Per Square Foot (Installed) Asphalt $0.50 to $1.00 Porous Concrete $2.00 to $6.50 Grass / gravel pavers $1.50 to $5.75 Interlocking Concrete Paving Blocks $5.00 to $10.00 Keep in mind that a more accurate price comparison would involve the costs of the full stormwater management paving system. For example, a grass / gravel paver and porous concrete representative stated that when impervious paving costs for drains, reinforced concrete pipes, catch basins, outfalls and stormwater connects are included, an asphalt or conventional concrete stormwater management paving system costs between $9.50 and $11.50 per square foot, compared to a permeable paving stormwater management system at $4.50 to $6.50 a square foot. The savings are considered to be even greater when pervious paving systems are calculated for their stormwater storage; if designed properly, they can eliminate retention pond requirements. Effectiveness All permeable pavements, including pervious asphalt, are on-site stormwater management practices and will have the same or very similar effectiveness with regards to the reduction of the volume and rate of stormwater runoff as well as pollutant concentrations. Porous asphalt, pervious concrete, and permeable pavers all have the same underlying stormwater storage and support structure. The only difference is the permeable surface treatment. The choice of permeable surface is relevant to user needs, cost, material availability, constructability, and maintenance, but it has minimal impact on the overall stormwater retention, detention, and treatment of the system. Durability Concrete durability is the ability to resist weathering action, chemical attack, and abrasion while maintaining desired engineering properties for the expected service life of the structure. Pervious concrete can become clogged, which directly affects the hydrologic performance and may indirectly affect other aspects of durability, such as freeze-thaw resistance, deicer salt scaling resistance, and sulfate resistance. Abrasion resistance of pervious concrete is also of concern, particularly in locations that use snow plows or have turning traffic. Carbonation and corrosion resistance are not concerns with pervious concrete as it is neither recommended nor necessary to use reinforcing steel bars or welded wire reinforcement. 3 Addition Information The bearing capacity of the roadbed must be as high as the bearing capacity for traditional pavement systems, even during rain events. Porous paving-stones show a higher risk of abrasion and damage because of their porous structure. Deicing salts and frost may damage the pavement during winter time. Porous concrete is especially sensitive to frost because of its open pores. Pollutants in the runoff can endanger soil and groundwater if they are not removed during infiltration. Especially heavy metals and hydrocarbons like oils from spillage and polycyclic aromatic hydrocarbons by combustion of engines must be retained in the pavement. Permeable pavements are sensitive to clogging. Suitable and cost effective cleaning methods must be developed that ensure a sufficient infiltration capacity. SUBJECT MATTER EXPERTS Two of the three Subject Matter Experts (SME) provided in this proposal are Professional Engineers (P.E.). The third SME provided in this proposal is an educator at Washington State University (WSU). All three have a number of years working with permeable pavements in projects, some of which are mentioned below. Their contact information can be found in Appendix 1. William (Bill) Lider PE,CESCL designed, pervious paver yard for the City of Seattle’s Lake Union Streetcar Maintenance Facility in Seattle, as well as a pervious concrete parking area for the Maltby Food Bank. Nathan Polanski, PE works for SvR Design Company which is a civil engineering/landscape architecture firm located in Seattle that specializes in low-impact development (LID) stormwater design and has designed dozens of projects with different types of permeable pavement systems – permeable pavers, porous asphalt and pervious concrete. Curtis Hinman leads the WSU Low Impact Development (LID) Research Program and has been involved with the program since its inception as a co-designer and managing construction. Mr. Hinman is Professor with Washington State University Extension. He is the author of the “Low Impact Development Technical Guidance Manual for Puget Sound” and the “Rain Garden Handbook for Western Washington Homeowners”. Mr. Hinman also serves on regional advisory committees that develop regional stormwater management policy and identify funding and research needs. 4 PRODUCT MATERIAL EXPERTS Two material resource suppliers, highly recommended by Curtis Hinman are Mutual Material Company and Abbotsford Concrete Products in Appendix 2. FUNDING RESOURCES There are four potential grant funding resources listed in Appendix 2. Funding provided by grants is based on very specific criteria and a projects’ ability to meet that criteria, so each funding resource must be assessed individually. ORDINANCES AND LINKS Appendix 3 includes the following: City of Seattle Code and Ordinances; Research References. 5