Biosafety Manual - Worcester Polytechnic Institute

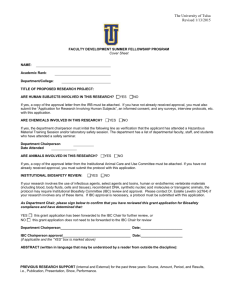

advertisement