Materials-Revision-N..

advertisement

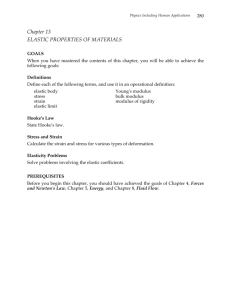

Deformation of Solids Forces can cause objects to change shape. The way in which an object deforms depends on material, size of the force and direction of the force. Hooke’s Law Measure how a spring stretches as you apply an increasing force to it and you get: F This shows that : fe In words, force is proportional to extension. This is Hooke’s Law. Any object behaving like this is said to be obeying Hooke’s law. In fact, many objects and materials obey e Hooke’s Law for part or all of their deformation, including glass and wire. The gradient of this graph is constant. Let’s call it ‘k’. The value of the constant can be found from: In words, ‘k’ is the force per unit extension. Rearrange to give: F = ke This is Hooke’s Law. ‘k’ is called the spring constant (or the spring stiffness). F Units for k: Nm-1 A stiffer spring has a greater value of spring constant. If you continue to stretch a spring it eventually comes to a point where it stops obeying Hooke’s Law. Stops obeying Hooke’s Law here – Elastic limit, E e The point on the graph where it stops obeying Hooke's Law is often called the 'limit of proportionality' because it is the last point at which the deformation of the material is proportional to the force acting on the material. At about the same moment as it stops obeying Hooke’s law, you will notice that if you unload the spring it won’t return to its original shape. It has been permanently deformed. We call this point the elastic limit – the limit of elastic behaviour. If a material returns to its original size and shape when you remove the forces stretching or deforming it, we say that the material is demonstrating elastic behaviour. Permanent deformation is a sign of plastic behaviour. Energy in Deformations F/N To calculate the energy stored in a deformed object, find the area under the force – extension graph. 10 In this example: Work = ½ force x extension = ½ x 10 x 0.02 = 0.1 J e/m 0.02 Some common examples to learn Note: + = breaking point. So glass breaks as soon as it stops obeying Hooke’s Law. Note: the rubber takes more energy to load up (area under the loading line) than it gives back when it unloads (area under the unloading line). The difference between these two (the area of the gap) is given out as heat. The rubber gets hot. This is known as a hysteresis curve. Stress and Strain The problem with force – extension graphs is that they only give information about the exact object and material that you are examining. Stress and strain are measurements that allow us to compare behaviour of materials and objects no matter what size or shape they are because the force and extension are multiplied up or down to find out what the force would be if it was spread over 1 m2 or what the extension would be per metre of the original material. Stress and Strain, Definitions Stress is defined as the force per unit area of a material. Stress = force / area . Units: Nm-2 or Pa. Strain is defined as extension per unit length. Strain = extension / original length. Strain has no units. For the description of the elastic properties of linear objects like wires, rods, columns that are either stretched or compressed, a convenient parameter is the ratio of the stress to the strain, a parameter called the Young's modulus of the material. Young's modulus can be used to predict the elongation or compression of an object as long as the stress is less than the yield strength of the material. Elastic Properties of Selected Engineering Materials Material Density Young's Modulus Ultimate Strength Su Yield Strength Sy (kg/m3) 109 N/m2 106 N/m2 106 N/m2 Steel 7860 200 400 250 Aluminium 2710 70 110 95 Glass 2190 65 50 ... Concrete 2320 30 40 ... Wood 525 13 50 ... Bone 1900 9 170 ... Polystyrene 1050 3 48 ... a Structural steel (ASTM-A36), b In compression, c High strength, d Douglas fir Data from Table 13-1, Halliday, Resnick, Walker, 5th Ed. Extended Stress - strain graphs Instead of force – extension graphs we can draw stress – strain graphs. In all the cases that you come across the shape of the graph is exactly the same as that for a force – extension graph. So here are some examples: Note: the gradient of a stress – strain graph = stress / strain. For the straight line (proportional) part of the graph while Hooke’s Law is obeyed, the gradient is constant. So stress / strain = a constant = E Or E = Fl We call this constant the Young Modulus and give it the symbol ‘E’. eA Units for Young Modulus: Nm-2 or Pa. The value of Young Modulus is always the same for a particular material, no matter what the size of the sample being tested. That’s one of the reasons why stress – strain graphs are more useful than force – extension graphs. ‘E’ gives a measure of the stiffness of a sample. A very big value of E suggests a very stiff material. (Note that E usually has massive values as stress (a big number) is divided by strain (a small number) to produce a huge result.) Energy in stress – strain graphs Note that the area under a stress – strain graph gives the energy stored per unit volume (how many joules are stored in 1m3 of the material) not just the energy stored. but Al = Area x Length = Volume so the equation becomes: Area = energy stored per unit volume which is the work done per unit volume the work done Deformation of solids f = ke - Hooke’s law Equations Stress/ Strain - stress equation Work = ½ force x extension - strain equation - Young’s modulus - Energy per m3 Symbols Deformation of solids Stress/ Strain F – Force, N E - Young Modulus, Nm-2 or Pa k - spring constant (or the spring stiffness). Nm-1 F - Force, N e – extension, m A - Area, m2 s - stress, Nm-2 or Pa e - strain, no units e - extension, m l – original length of material, m Glossary Tensile / tension forces: forces stretching something. Compressive / compression forces: forces squashing something. Elastic deformation: Non-permanent, the object returns to its original shape when the forces are removed. Plastic deformation: permanent deformation. Brittle: a material that can’t deform plastically without breaking. Ductile: a material that can undergo extensive plastic deformation without breaking. Hard: very difficult to scratch or mark Strong: will not break easily under tension or compression. Ultimate tensile strength: the maximum tensile force that an object / material can stand. Useful Web sites: Hooke’s Law applet: http://webphysics.davidson.edu/Applets/animator4/demo_hook.html Practical analysis of Hooke’s law: http://www.phys.utk.edu/labs/pl232hl.pdf Simplified investigation: http://www.frontiernet.net/~jlkeefer/hookes.html Values in Periodic Table: http://www.webelements.com/webelements/properties/text/definitions/youngs-modulus.html#def Notes on Young’s Modulus: http://hyperphysics.phy-astr.gsu.edu/hbase/permot3.html Experimental investigation: http://schools.matter.org.uk/Content/YoungModulus/experiment_1.html http://pergatory.mit.edu/2.007/handouts/bending/bending.pdf Spider’s web example: http://www.tiem.utk.edu/~gross/bioed/bealsmodules/spider.html