summary notes - Kinross High School

advertisement

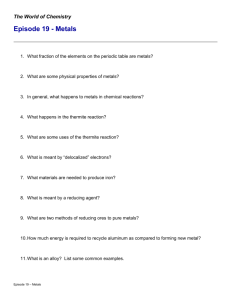

Chemistry in Society – Summary File Given below are some of the basics of what you will need to know for this topic. In order to make sure that you have revised all aspects of the unit, you also will have to look at your noted booklet. Metals and Alloys Metals are a type of element, clearly marked in the periodic table. The alkali metals (group 1) and the transition metals are metals that all have similar chemical properties. Metals are hard, shiny, conductors of heat and electricity, ductile (able to be drawn into wires) and malleable (able to be beaten into shape). All metals are solid, bar mercury which is a liquid at room temperature. Metal all conduct electricity due to having delocalised electrons. Alloys are mixtures of metals with improved properties, e.g. solder has a lower meting point than lead and tin which make it up. Metals are finite and will run out thus the price of them is increasing and we are trying to find better ways of recycling them. Reactivity Series: Metals can all be placed in a reactivity series, with the most reactive metals at the top. Metals react with oxygen, water and dilute acid. Differences in the reaction rates give an indication of the reactivity of the metal. Metal + oxygen -> Metal Oxide Metal + Water -> Metal hydroxide + hydrogen Metal + Acid -> a Salt + hydrogen Ores are naturally occurring compounds of metals. The less reactive metals, including gold, silver and copper, are found uncombined in the Earth’s crust and the more reactive metals have to be extracted from their ores. Some metals can be obtained from metal oxides by heat alone; some metal oxides need to be heated with other substances, e.g. carbon or carbon monoxide; other metals cannot be obtained by these methods. Iron is produced from iron ore in the Blast Furnace. The production of carbon monoxide and the reduction of iron oxide are the two key reactions which take place in the Blast Furnace. The more reactive metals, including aluminium, are obtained by electrolysis. Electrochemical Cells: Electricity can be produced by connecting different metals together, with an electrolyte, to form a simple cell. The cathode and the anode must be different metals to produce a voltage. The electrolyte must be an ionic solution in order for the ions to be free to move. The voltage between different pairs of metals varies and this leads to the electrochemical series. The greater the difference Displacement reactions occur when a metal is added to a solution containing ions of a metal lower in the electrochemical series. The reaction of metals with acids can establish the position of hydrogen in the electrochemical series. Electricity can be produced in a cell by connecting two different metals in solutions of their metal ions. Electricity can be produced in a cell when at least one of the half-cells does not involve metal atoms. Electrons flow in the external circuit (through the wire) from the species higher in the electrochemical series to the one lower in the electrochemical series. The purpose of the ‘ion bridge’ (salt bridge) is to allow the movement of ions to complete the circuit. Using Electricity: Electrolysis is the splitting up of an ionic compound using electricity. Electricity can be used to electroplate, purify or protect metals. Anodising is the protection of aluminium using an aluminium oxide coating. Corrosion: Corrosion is a chemical reaction which involves the surface of a metal changing from an element to a compound. Different metals corrode at different rates. The term rusting is applied to the corrosion of iron. Both water and oxygen, from the air, are required for rusting. When iron rusts, initially the iron atom loses two electrons to form iron (II) ions which can be oxidised further to give iron (III) ions. Electrons lost by the iron during rusting are accepted by the water and oxygen to form hydroxide ions. Ferroxyl indicator can be used to detect the presence of iron(II) ions and hydroxide ions and turns blue in the presence of Fe2+ ions. Acid rain increases the rate of corrosion and acid acts as an electrolyte. Salt spread on roads increases the rate of corrosion on car bodywork as salt acts as an electrolyte. When attached to metals higher in the electrochemical series, electrons flow to the iron, and when attached to metals lower down in the series, electrons flow from the iron. Iron does not rust when attached to the negative terminal of a battery. This is called cathodic protection Electrons flowing to the iron prevents rusting. Anti-corrosion methods are used in everyday situations. Painting, greasing, electroplating, galvanising, tin-plating and coating with plastic give a surface barrier to air and water which can provide physical protection against corrosion. Galvanising (covering iron in zinc) and the use of scrap magnesium result in electrons flowing to the iron giving sacrificial protection. Scratching tinplate increases the rate of rusting of iron. Metals Metallic bonding joins metals together as positive nuclei are surrounded by a sea of delocalised electrons (which allows conduction). Oxidation is a loss of electrons by a reactant in any reaction. A metal element reacting to form a compound is an example of oxidation. Reduction is a gain of electrons by a reactant in any reaction. A compound reacting to form a metal is an example of reduction. In a redox reaction, reduction and oxidation go on together. Ion-electron equations can be written for oxidation and reduction reactions (see data book). During electrolysis, oxidation occurs at the positive electrode and reduction occurs at the negative electrode. Fuel cells produce electricity using reactions of hydrogen and oxygen. Materials and Plastics Synthetic materials are made by the chemical industry. Most plastics and synthetic fibres are made from chemicals derived from oil. Examples of plastics include polythene, polystyrene, perspex, PVC, nylon, bakelite, formica and silicones. Kevlar, which is very strong, and poly(ethenol), which readily dissolves in water, are recently developed plastics. The everyday uses of plastics are related to their properties. Examples of synthetic fibres include polyesters, e.g. Terylene, and nylon. For some uses, synthetic materials have advantages over natural materials and vice versa. Biopol is a recently developed degradable plastic. Most plastics are not biodegradable (i.e. do not break down naturally) and their low density and durability can cause environmental problems. Some plastics burn or smoulder to give off toxic fumes, including carbon monoxide. The toxic gases given off during burning or smouldering can be related to the elements present in the plastic (PVC=HCl and polyurethane = hydrogen cyanide HCN). Plastics can be either thermoplastic or thermosetting. A thermoplastic is one which can be reshaped on heating. A thermosetting plastic cannot be reshaped by heating. Monomers are small molecules, polymers are large and monomers join up to form polymers in a polymerisation reaction. Addition polymerisation Plastics are made up of long chain molecules called polymers .Polymer molecules are made from many small molecules called monomers. Addition polymers are made from small unsaturated molecules produced by cracking by a process called addition polymerisation. The small unsaturated molecules join together by the opening of the carbon to carbon double bond. The name of the addition polymer is related to the name of the monomer. The repeating unit or the structure of an addition polymer can be drawn given the monomer structure and vice versa. Condensation polymerisation Condensation polymers are made from monomers with two functional groups per molecule. The repeating unit or the structure of a condensation polymer can be drawn given the monomer structures and vice versa. Polyesters are examples of condensation polymers. An amine can be identified from the functional group. Polyamides are examples of condensation polymers. Fertilisers: Fertilisers contain the elements N, P and K as these are the essential elements needed by plants for growth. The Haber process takes nitrogen from the air and hydrogen from natural gas to make ammonia (alkaline gas, NH3). An iron catalyst is used as is high pressure and moderately high temperatures. The Ostwald Process takes ammonia and oxygen to make nitric acid. This is used to make fertilisers. This is an exothermic reaction and uses a platinum catalyst. You should be able to do percentage by mass calculations. Nuclear Chemistry: The atom has the following structure: Protons and neutrons have mass 1 and electrons have almost no mass. Isotopes have the same atomic number but different mass numbers, i.e. they have different numbers of neutrons. There are 3 main types of radioactivity, that can be used for a number of uses, including medicine and energy generation: Half-life is the time it takes for radiation to decrease by half. You should expect to be able to do half-life calculations. Chemical Analysis: The concentration of acids/alkalis can be calculated from the results of volumetric titrations. You should be able to do a variety of problem solving and calculations on this topic. This is a summary of what is in this topic – please look at your notes for further information.