DP2 Technical Report

advertisement

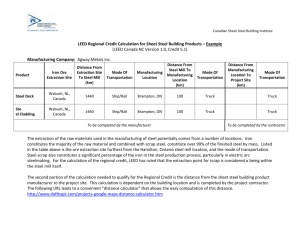

EDSGN100 Design Project #2 Final Design Report Recycling of Advanced High Strength Steel Introduction to Engineering Design EDGSN 100 Section 014 Fiddle Stix Design Co. Team 1 Aaron Toldi, http://www.personal.psu.edu/ajt5354, ajt5354@psu.edu Kody Belli, http://www.personal.psu.edu/kjb5505, kjb5505@psu.edu Ahmed Alamoudi, http://www.personal.psu.edu/ama5753, ama5753@psu.edu Submitted to: Prof. Berezniak Date: 04/26/2012 1 Spring 2012 Recycling of Advanced High Strength Steel Executive Summary Table of Contents 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 Introduction……………………………………………………………………….…………. Project Background.………………………………………………………………………. Project Objectives.………………………………..………….………………..…………. Project Requirements……………………………………….…………….….…………. Design Constraints/Assumptions….……….…………….…………..……………. 5.1 Economic…………………………………………………..…………..…….……. 5.2 Environmental……………………………….……..……..……………………. 5.3 Sustainability……………….…………………….…………………..…….……. 5.4 Technical/Manufacturing……………………….…………...……………. 5.5 Social and Political……………………………………….………..……………. 5.6 Public Health and Safety………….……………………..……….…..……. 5.7 Legal/Ethical……………………………..…………………………….…………. 5.8 Critical Assumptions………………..…………………………….…………. Codes and Standards……………………………………..……………………..………. Conceptual Design..….………………………..………………………..…………….…. Final Design..….………………………………………………….……………………….…. Results…………………………………………………………………………………………… Conclusions…………………………………………………………………………………… References………………………………………………….………………………………… Page 3 Page 3 Page 3 Page 3 Page 3 Page 3 Page 4 Page 4 Page 4 Page 4 Page 4 Page 4 Page 4 Page 5 Page 5 Page 5 Page 5 Page 6 Page 6 List of Figures Figure 1 Figure 2 Figure 3 Scrap Process …………………………………………………….………..… Page 6 Process-Flow Diagram….…………………………………….………..… Page 7 Alloy Tester .……………………………………………………….………..… Page 7 2 Spring 2012 Abstract (Executive Summary) The objective of this project was to design a sustainable and efficient process to recycle steel metal scrap from used automobiles. As a team, we were to design a system that would separate the steel components of the car by the different alloys used in each part. We created an alloy tester that sends electric current through the steel and identifies the alloy used by the charge produced when a hot and cold current are sent through opposite sides, using a method called the Thermoelectric Effect. Our total process is completely sustainable, by extracting the toxic substances from the automobile and disposing of the non-steel parts, scrapping the remaining parts, then finally testing the steel to be separated by alloy and sent to the required factory to be recycled into future steel making. 1.0 Introduction The project is to come up with a design to better recycle new high strength steel alloys and keep it separate from other steel scrap throughout the scrap cycle. Our design team realized the best way to separate the AHSS from other steel scrap was during the car scrapping process. This method is the most efficient and cost effective. It utilizes what already exist with just some minor alterations to get the job done. 2.0 Project Background ArcelorMittal, as a customer, has asked us to redesign the steel recycling process. We are to create a process that will separate the steel by alloy to recycle it back to the steel manufacturers. The company is looking for a cradle-to-cradle process that will limit those natural resources taken from the earth. While there are large known quantities of these resources, they are finite and will eventually run out. ArcelorMittal is asking for a sustainable recycling process that will follow environmental and socioeconomic constraints, as well as being completely efficient. Right now, 30% of new steel is recycled. As we progress into the future, this percentage should increase so that as much new steel as possible is made from scrap steel. 3.0 Project Objectives The objective of this project is to develop a process to effectively recycle AHSS. The process developed must be cost and socioeconomically effective, and environmentally friendly. 4.0 Project Requirements The main requirement of this project is the effective separation of AHSS from line pipe steel. This is important as the alloy products in line pipe pieces can cause an off chemistry heat and those alloys could be in a heat to make more high alloy steel. 5.0 Design Constraints/Assumptions 5.1 Economic Seeing as salvage yards currently remove recyclable materials from the vehicles, this process won’t add much more cost to implement. Some new costs will include thermoelectric metal detectors and perhaps a cutting device for the removal of AHSS from the regular steel. 3 Spring 2012 The separation of the two types of scrap may increase shipping costs slightly, but the same weight of material would be moved either way. 5.2 Environmental The process of breaking down the vehicle should be entirely indoors in order to prevent run off of toxic chemicals. The toxic chemicals in the vehicle should all be drained prior to disassembling the vehicle, and then reclaimed. All chemicals drained should be stored in collection barrels. Spills which impact soil, surface water or ground water should be reported to the appropriate authority. All salvage yards should meet EPA regulations, hopefully their own standards exceed the EPA standards. 5.3 Sustainability The design enables effective recycling of all vehicle parts. There is no part of this process that creates waste which does not already exist. No part of this process requires a large amount of energy or new materials. This process is very sustainable. 5.4 Technical/Manufacturing If the salvage vehicle is broken down effectively, it is almost entirely recyclable. Any waste can be separated and properly disposed of. There should only be short term storage of materials prior to shipping them to the appropriate facility to be processed. The AHSS scrap will be stored and shipped separately from the other steel. After the AHSS is stripped from the vehicle, the frame can be crushed and shredded. 5.5 Social and Political If done entirely indoors the public and environment will not be negatively impacted by the process. The air can be filtered to collect any dust or chemicals. This process has the potential to create more jobs. Considering it is also about recycling and saving money, it should be well received by the public. 5.6 Occupational Health and Safety As potentially toxic materials exist in cars, it is necessary for personnel scrapping them to wear the appropriate PPE. The PPE can also protect personnel from physical harm in the industrial workplace. There are some hazards associated with the vehicle scrapping process but proper training and equipment will drastically reduce the risk of these. 5.7 Legal/Ethical There are many chemicals and other materials recovered from the salvage vehicles which must be handled within government regulations. One of the more notable chemicals is the refrigerant in the air conditioner. Refrigerant recovery equipment must be certified by an independent testing organization to meet EPA standards. The EPA prohibits venting refrigerant to the atmosphere. Refrigerants also have special storage and labeling requirements. All salvage yards should already be meeting these standards. The only addition our process creates is the cutting out of AHSS. This may create emissions from cutting the metal, the emissions from which are not monitored by the EPA but by OSHA, because they are potentially toxic to the workers. 5.8 Critical Assumptions The first critical assumption is that most salvage yards which fully or near fully recycle vehicles already exists. The second is that there will be some incentive for the salvage yards to separate the AHSS from the regular steel. 4 Spring 2012 6.0 Codes and Standards Most states have salvage laws which require the buyer of the salvage vehicle to keep a record of the seller and contact law enforcement and the NMVTIS with vehicle information. This is to prevent the sale of stolen property. Many recycling laws already exist and will not be violated by this process. There are many laws regarding the environmental and occupational safety of salvage yards. If interested in researching these laws, check out the resources. 7.0 Conceptual Design The mass separation of shredded scrap is not feasible. The high alloy steel must be separated from the other steel prior to it arriving at the steel mill. This must be accomplished when scrapping the vehicle. There are a few ways to accomplish this. The first way would be to have a computer readily available with information about which car parts contain AHSS so these can be removed from the rest. A person with more experience with the specific type of vehicle could do this more quickly. So it seems that an effective method would be for some company or companies to recycle vehicles on a much larger scale than currently being done. Another method would involve using some a method of detection to find which metals are AHSS at existing scrap yards. It appears a thermoelectric metal tester would be the fastest way to accomplish this, but just researching which parts are made of AHSS might be as effective. 8.0 Final Design Our final design involves taking existing salvage yards and having them separate the AHSS from the other steel. Our design is a process which involves cutting out the AHSS as part of the recycling process. The ideal way this process works is part of the way which cars are already recycled. First, all chemicals are drained from the vehicle. Then any parts with hazardous or precious materials are removed. Next the tires, glass any other rubber, all the cables and engine. Then the interior parts are removed, such as the dash and seats. After all those parts are removed the AHSS can then be cut out. The way to identify which parts are AHSS and which are not could be done either by researching which parts are AHSS or using an electric alloy detector. The AHSS is then kept separate from the regular steel throughout the scrap cycle. The rest of the car can then be crushed and shredded as per usual. (see Figure 1) 10.0 Results The design here isn’t reinventing the wheel but it seems to be the most effective way to separate the steel scrap. To visualize our process refer to figures 1 and 2. By using this process, we can better separate the scrap and recycle the steel by its alloy make-up. This method will help to increase the percentage of new steel that is made from recycled scrap. The process is effective, efficient, and sustainable. 5 Spring 2012 11.0 Conclusions This project was a great success. The process we developed enables the full recycling of vehicles, and met the requirements for this project. It uses a very sustainable, environmentally friendly process. It enables the separation of AHSS from other scrap to alloy the alloys to be reused to reduce the cost of new alloys and it won’t affect the chemistry of other heats. 12.0 References “ScrapLaws.com - Laws, Resources, Prices and News for Recyclers of Metal, Paper, Plastic, Etc." ScrapLaws.com. 2011. Web. 20 Apr. 2012. <http://www.scraplaws.com/>. "World Auto Steel." - Steel Is Green. Web. 20 Apr. 2012. <http://www.worldautosteel.org/>. “Environmental Compliance Guide for Motor Vehicle Salvage Yards.” Ohio EPA. Web. 20 Apr. 2012. < http://www.epa.ohio.gov/portals/41/sb/publications/salvageguide.pdf>. ArcelorMittal Project Statement Figures Figure 1 Scrap Process. Process of car being broken down at scrap yard into its separate components. 6 Spring 2012 Figure 2 Process-Flow Diagram. Flow diagram breakdown of where each step will take place. Figure 3 Alloy Tester. Uses the Thermoelectric Effect to use heat currents to test for the charge of the alloy used. 7 Spring 2012