pola27761-sup-0001-suppinfo

advertisement

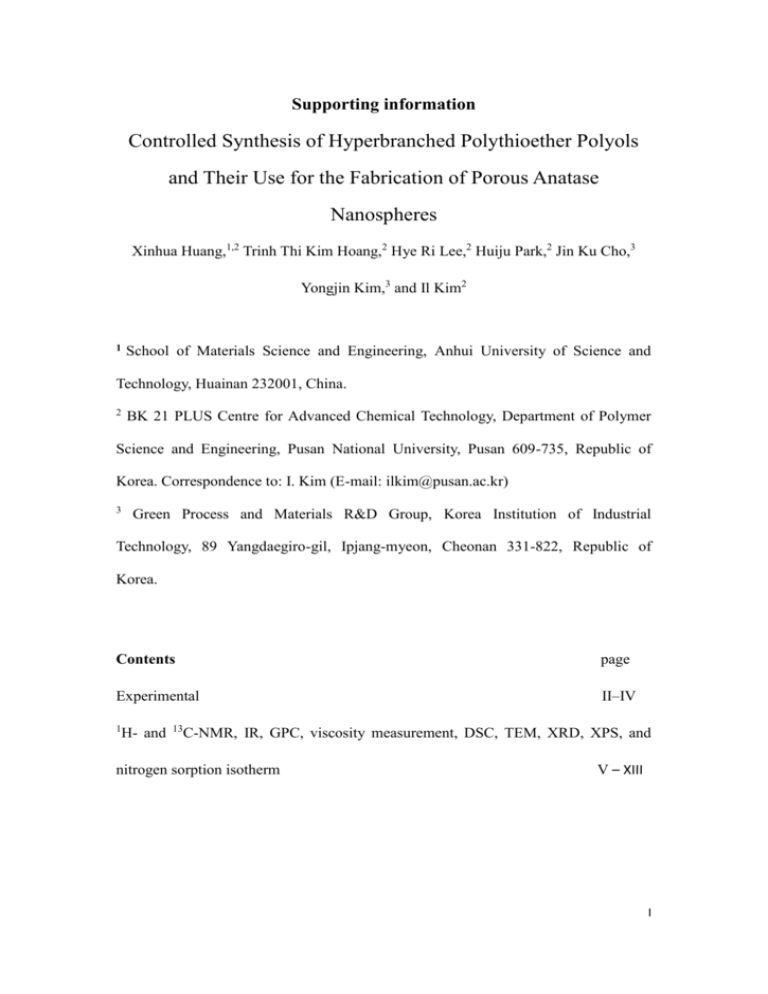

Supporting information Controlled Synthesis of Hyperbranched Polythioether Polyols and Their Use for the Fabrication of Porous Anatase Nanospheres Xinhua Huang,1,2 Trinh Thi Kim Hoang,2 Hye Ri Lee,2 Huiju Park,2 Jin Ku Cho,3 Yongjin Kim,3 and Il Kim2 1 School of Materials Science and Engineering, Anhui University of Science and Technology, Huainan 232001, China. 2 BK 21 PLUS Centre for Advanced Chemical Technology, Department of Polymer Science and Engineering, Pusan National University, Pusan 609-735, Republic of Korea. Correspondence to: I. Kim (E-mail: ilkim@pusan.ac.kr) 3 Green Process and Materials R&D Group, Korea Institution of Industrial Technology, 89 Yangdaegiro-gil, Ipjang-myeon, Cheonan 331-822, Republic of Korea. Contents page Experimental II–IV 1 H- and 13 C-NMR, IR, GPC, viscosity measurement, DSC, TEM, XRD, XPS, and nitrogen sorption isotherm V – XIII I EXPERIMENTAL Materials. TMP (97%, Sigma-Aldrich), VCHO (98%, Sigma-Aldrich), 1-thioglycerol (> 95%, Tokyo Chemical Industry Co., LTD), azobisisobutyronitrile (AIBN, 98%, Junsei Chemical Co., Ltd), potassium hydride (KH, 30 wt% dispersion in mineral oil, Sigma-Aldrich), Titanium (IV) isopropoxide (TTIP, purum, Sigma-Aldrich), methanol (extra pure, moisture < 0.3%, Daejung). Anhydrous DMSO was obtained from Sigma-Aldrich and used as received. Synthesis of sulfur containing epoxide monomer. A solution of AIBN (130 mg, 0.8 mmol) in degassed methanol (40 mL) was added drop-wise over 4 h to a refluxing solution of VCHO (5.0 g, 40 mmol) and 1-thioglycerol (6.5 g, 60 mmol) in degassed methanol (7.0 mL) under an N2 atmosphere. The solution was refluxed for a further 16 h. The reaction mixture was then concentrated in vacuo to 1/3 of its initial volume. The concentrated solution was then precipitated in diethyl ether 3 times. Finally, the resulting product, 3-[2-(7-oxa-bicyclo[4.1.0]hept-3-yl)-ethylsulfanyl]-propane-1,2diol (CESPO), was dried in vacuo at 70 ºC for 8 h as a yellow liquid (yield 95 %).1H NMR (400 MHz, D2O): δ = 3.71 (m, 2H, epoxy VCHO), 3.55-3.41 (m, 2H), 3.22 (s, 1H), 2.70-2.51 (m, 4H), 1.49-1.56 (m, 5H).FAB-MS m/z (%) 215.11 (100) [M-OH]+ Polymerization of CESPO. A typical polymerization procedure is as follows: A suspension of KH in mineral oil (30% in weight) was introduced to a dry, pre-weighed 100 mL three-neck round-bottom flask in a nitrogenous atmosphere. The mineral oil was then removed by three extractions with THF, and the residual THF was removed by vacuum. When the apparatus was completely dried, the flask was weighed again to determine the amount of KH (typically 10 mg, 0.25 mmol). Then DMSO (10 mL) and TMP (335 mg, 1.25 mmol) were introduced to the flask. The solution was stirred for 30 min to form the potassium alcoholate. Subsequently, II CESPO(5.8 g, 25.0 mmol) in 20 mL DMSO was added by syringe over 10 h, and the solution was heated to 80 °C for a further 48 h. Upon completion of the polymerization, the mixture was precipitated in an acetone/diethyl ether mixture (500 mL, v/v = 1/4). The product was re-dissolved in methanol and neutralized by filtration over cation-exchange resin. The obtained HPTE was precipitated twice from methanol solution in cold diethyl ether and then dried invacuo at 60 °C for 8 h. Using the same process, a series of HPTEs with different molecular weights were synthesized by varying the TMP/CESPO molar ratio (see Table 1). The resultant purified products were highly viscous. 1H NMR (400 MHz, DMSO-d6): δ = 4.5-5.6 (OH); 5.2-4.4 (OH); 2.1-3.0 (CH2 in the linear chains); 3.4-3.8 (CH); 2.0-0.9 (CH2 in the cyclohexane and CH3 in TMP). Synthesis of TiO2. In a typical synthesis, 50 mg of HPTE was dissolved in 10 mL methanol. 10 μL of TTIP was then slowly added to the solution with vigorous stirring for 2 h at room temperature, forming a white suspension. This was then centrifuged at 6000 rpm for 30 min to obtain the product as a white solid. The solid was then washed three times with methanol and dried at 60 ˚C in vacuo. The dried solid was sintered at 350 ˚C to obtain TiO2 nanocrystals. Characterization. 1H and 13 C NMR spectra of the polymers were recorded using a 400 MHz 1H (100 MHz 13C)spectrometer (Varian Unity Plus)with D2O and DMSO-d6 as solvent, respectively. The fast-atom bombardment mass spectra (FAB-MS) were recorded on a JEOL JMS DX300 apparatus (JEOL, Tokyo, Japan). Gel permeation chromatography (GPC) was performed on a Waters 2410 system equipped with a refractive index detector, using poly(methylmethacrylate) as the calibrant. Dimethyl formamide containing 0.01 mol/L lithium bromide was used as the mobile phase at a flow rate of 1 mL/min at 40 °C. Small drops of the HPTEs liquid were spread on a dry III KBr disc and were vacuum dried at 80 ºC for 6 h to reduce the levels of adsorbed water in the samples prior to recording their Fourier transform infrared (FTIR) spectra under ambient conditions on a Shimadzu IR Prestige-21 (Kyoto, Japan) spectrophotometer. Each sample was scanned 50 times with a resolution setting of 4 cm-1over the range of 4000-400 cm−1.A TA Instruments Q-1000differential scanning calorimeter (DSC) was used from -100 to 20 °C at a heating rate of 10 °C/min with a 2 min isotherm at the maximum and minimum temperatures. The glass transition temperature (Tg) was measured in a second heating scan.The thermogravimetric analysis (TGA, Scinco, TGAN-1000) was performed over the range of 30 to 800 ˚C in steps of 10 ˚C min-1 under a high-purity N2 flow (10 cm3 min-1).Viscosimetry measurements were performed on a Schott AVS/6 Ubbelohde dilution viscosimeter at 25 ˚C using a capillary with a diameter of 0.46 mm and using methanol as the solvent. The structures of the TiO2 species were examined using X-ray diffraction (XRD) using an automatic Philips powder diffractometer with nickel-filtered Cu Kα radiation. The diffraction pattern was collected over a 2θ range of 10-80° in steps of 0.02° with counting times of 2 s step−1. The surface characteristics were analyzed using a PHI 5400 X-ray photoelectron spectroscope (XPS, Physical Electronics, Mg Kα source). The microstructures of the samples were investigated using an S-4800 scanning electron microscope (SEM; Hitachi, Japan), and a JEM-2100F HR transmission electron microscope (TEM). IV Figure S1. NMR spectra of polythioether HPTE-1, obtained by OROP initiated with TMP: (A) 1H NMR spectrum in DMSO-d6; (B) 13 C NMR spectrum in DMSO-d6 showing carbons corresponding to the T, DE, DT, L13, and L14 units. V Figure S2.1H NMR spectra of different HPTEs in D2O. Figure S3.13C NMR spectra of different HPTEs in DMSO-d6. VI Figure S4. FT-IR spectra of different HPTEs: (a) HPTE-1, (b) HPTE-2, (c) HPTE-3, (d)HPTE-4, and (e) HPTE-5. Figure S5. GPC curves of different HPTEs: (a) HPTE-1, (b) HPTE-2, (c) HPTE-3, (d)HPTE-4, and (e) HPTE-5. VII Figure S6. Specfic viscosity (ηsp) of HPTEs as a function of concentration in methanol at 25 ˚C. Figure S7.DSC thermograms of HPTEs synthesized viaslowmonomer addition method in DMSO solvent. VIII Figure S8. TEM images of TiO2 samples taken at different times of reaction. The scale bar is 100 nm. IX Figure S9. TEM images of the titanic nanostructure with different HPTEs (10 mg/mL in methanol) as template:(A) HPTE-1,(B) HPTE-2,(C) HPTE-3, (D) HPTE-4, and (E) HPTE-5. The scale bar is 100 nm. X Figure S10. Wide angle XRD patterns of TiO2templateed by different by HPTEs: (a) HPTE-1, (b) HPTE-2, (c) HPTE-3, and (d) HPTE-4. Figure S11. (a) Wide XPS spectrum of the TiO2 porous particles templated by HPTE-5, the reference C1s is at 284.6eV; (b) the corresponding high resolution XPS spectra of Ti 2p. XI Figure S12. TEM images of the titanic nanostructure with different concentrations of HPTE-3 as template in methanol solution: A) 5 mg/mL, B) 10 mg/mL, C) 15 mg/mL, D) 20 mg/mL, and E) 30 mg/mL. The scale bar is 200 nm. XII Figure S13.Nitrogen sorption isotherms (inset: BJH pore size distribution) of TiO2 templated by (A) HPTE-1, (B) HPTE-2, (C) HPTE-3, (D) HPTE-4, and (E) HPTE-5. XIII