aic14700-sup-0001-suppinfo

advertisement

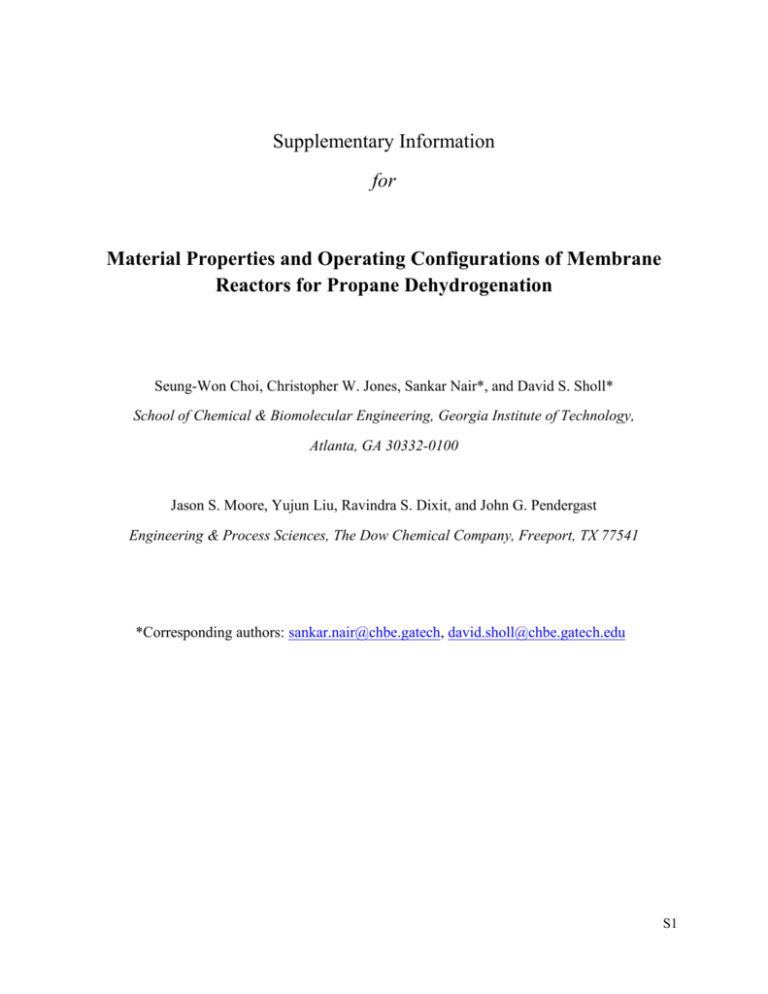

Supplementary Information for Material Properties and Operating Configurations of Membrane Reactors for Propane Dehydrogenation Seung-Won Choi, Christopher W. Jones, Sankar Nair*, and David S. Sholl* School of Chemical & Biomolecular Engineering, Georgia Institute of Technology, Atlanta, GA 30332-0100 Jason S. Moore, Yujun Liu, Ravindra S. Dixit, and John G. Pendergast Engineering & Process Sciences, The Dow Chemical Company, Freeport, TX 77541 *Corresponding authors: sankar.nair@chbe.gatech, david.sholl@chbe.gatech.edu S1 Dimensionless Energy Balance Equations and Boundary Conditions dT = dz Peheat B.C. L 1 d dT r R r dr dr 2 z = 0 , r = 0 , d 2T -H -r + A 2 + Da C pT0 Peheat dz (Tube) d T =0 dz dT d T hR =0, r =1, = M - T dr dr keff (S1) 0 = 1 , z = 1 , keff , heat = C p Peheat = (S2) heat uL (S3) Here represents dimensionless temperature which is defined by temperature divided by inlet temperature (T0). The governing equations include thermal diffusivity (heat) and Péclet number for heat transfer as generally defined above. The keff is effective thermal diffusivity and and Cp denote average density and heat capacity respectively. The u is linear velocity along the axial direction and h is heat transfer coefficient. The Da and dimensionless reaction term in Equation S1 are the same as what we use in the mass transfer equation. For the membrane side, we consider heat conduction across the support as follows: 1 d d m r = 0 r dr dr (Membrane support) (S4) S2 r = 0 , r = 1 , B.C. h d M = m M - T dr keff h m d M = S - M dr keff (S5) We also set up a heat transfer equation for the shell side as follows: 2 L 1 d d s d s = r dz Peheat S r dr dr B.C. r = 0 , r = 1 , (Shell) (S6) d s h = S s - m , r = 1 , dr k gas d s = 0 (adiatatic) dr d s h S Tw = (non - adiatatic) w - s , w = dr k gas Ts (S7) The subscripts t. m and s denote the tube, membrane and shell sides. For each side, the characteristic length in radial direction is the radial distance between its radial boundaries. For example, for the shell side the characteristic length (s) is from the boundary between membrane support and the shell side to the outer wall of the reactor. We assume constant wall heat flux with fixed heat transfer coefficient, which is estimated based on Nusselt number in plug flow. The average heat capacity and conductivity for the gas mixture are estimated by extrapolating gas property data provided by NIST to 600°C, and are assumed to be constant throughout the reactor. The gas density is calculated from equation of state at 1 atm and 600°C. The heat transfer equation parameters are summarized in Table S1. S3 Table S1. Parameter values for heat transfer equation. Parameter Value H, J.mol-1 125,000 h, W.m-2.K 59.2 kgas, W.m-1.K 0.04 Cp, J.g-1.K 4.1 kg.m-3 (inlet) 0.614 Notation H : Heat of reaction (J.mol-1) Cp : Average heat capacity (J.g-1.K) h : Heat transfer coefficient (W.m-2.K) heat : thermal diffusivity (m2.s-1) gas : Average density of gas component (g.m-3) keff : Effective thermal conductivity (W.m-1.K) : Dimensionless temperature S4