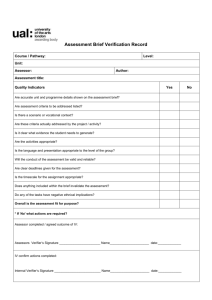

Assessment Guidelines for Engineering Maintenance

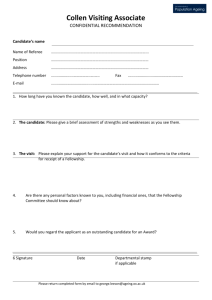

advertisement