POLA_26304_sm_SuppInfo

advertisement

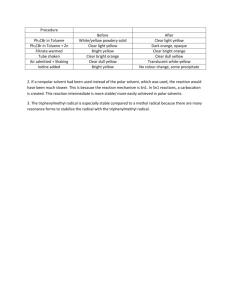

Domino Synthesis of Star-Shaped Polymers Based on Monomer Selective Living Cationic Polymerization: Highly Controlled Star Polymer Formation Shokyoku Kanaoka, Mayuka Yamada, Jun Ashida, Arihiro Kanazawa, and Sadahito Aoshima Department of Macromolecular Science, Graduate School of Science, Osaka University, Toyonaka, Osaka 560-0043, Japan Tel & Fax: +81-6-6850-5448 E-mail: aoshima@chem.sci.osaka-u.ac.jp Supporting Information I. Materials……………………………………………………………………………….S1 II. Characterization………………………………………………………………………S2 III. Domino Synthesis of Block Copolymers……………………………………………S2 IV. Domino Synthesis of Star-Shaped Polymers………………………………………...S4 V. Reference……………………………………………………………………………..S6 I. Materials Isobutyl vinyl ether [IBVE (TCI; >99%)], p-tert-butoxystyrene [tBOS (Wako; 98.0%)], 1,4-cyclohexanedimethanol divinyl ether [DVE (Aldrich; 99%)], and 1,4-diisopropenyl benzene [DIPB (TCI; >98.0%)] were washed with 10% aqueous sodium hydroxide solution and then water, dried overnight over potassium hydroxide pellets, and distilled twice over calcium hydride before use. Ethyl acetate (Wako; >99.5%), heptane (TCI; >99.0%), and 2,6-di-tert-butylpyridine [DTBP (Wako; 97.0%)] were distilled twice over calcium hydride before use. A divinyl compound with two alkoxystyryl moieties [1,3-bis(4-vinylphenoxy)propane; BVP] was prepared from p-acetoxystyrene and 1,3-dibromopropane as previously reported.1 BVP was purified by recrystallization from methanol and then from ethyl acetate, and vacuum-dried for over 3 h prior to use. Toluene (Wako; 99.5%) and dichloromethane (Nacalai Tesque; 99%) were purified by passage through solvent purification columns (Glass Contour). 1-(Isobutoxy)ethyl acetate S1 [IBEA; CH3CH(OiBu)OCOCH3; IBEA] was prepared by the reaction of acetic acid with the corresponding vinyl ethers as previously reported.2 Commercially available SnCl4 (Aldrich; 1.0 M solution in heptane), EtAlCl2 (Wako; 1.0 M solution in hexane) and TiCl4 (Aldrich; 1.0 M solution in toluene) were used without further purification. All materials except for dichloromethane, toluene and BVP were stored in brown ampules under dry nitrogen. II. Characterization The molecular weight distribution (MWD) of the polymers was measured by gel permeation chromatography (GPC) in chloroform at 40 ºC with three polystyrene gel columns [Tosoh; TSK gel G-4000HXL, G-3000HXL, and G-2000HXL (exclusion limit molecular weight = 4 × 105, 6 × 104, and 1 × 104, respectively; bead size = 5 μm; column size = 7.8 mm internal diameter × 300 mm) or TSK gel MultiporeHXL-M × 3 (exclusion limit molecular weight = 2 × 106; bead size = 4 μm; column size = 7.8 mm internal diameter × 300 mm); flow rate = 1.0 mL/min] connected to a Tosoh DP-8020 pump, a CO-8020 column oven, a UV-8020 ultraviolet detector, and an RI-8020 refractive-index detector. The number-average molecular weight (Mn) and polydispersity ratio [weight-average molecular weight/number-average molecular weight (Mw/Mn)] were calculated from the chromatographs with respect to 16 polystyrene standards (Tosoh; Mn = 291– 1.09 × 106, Mw/Mn ≤1.1). The weight-average molecular weights (Mw) of the star polymers were determined by GPC coupled with multi-angle light scattering (GPC–MALS) in chloroform at 40 ºC on a DAWN HELEOS (Wyatt Technology; Ga-As laser, = 690 nm). Based on the Mw values, the average number of arms of star-shape polymers was calculated by the following equation: The number of arms = M w of star polymer ´ weight fraction of linear segments M w of linear polymer The refractive index increment (dn/dc) values were measured in chloroform on differential refractometer (Otsuka Electronics DRM-3000; = 633 nm). NMR spectra were recorded using a JEOL JNM-LA 500 spectrometer (500 MHz for 1H). III. Domino Synthesis of Block Copolymers Synthesis of block copolymers was conducted at 0 ºC under dry nitrogen atmosphere in a glass tube with a three-way stopcock baked over 300 ºC for 10 min before use. Domino synthesis of block S2 copolymers in toluene at 0 ºC is as follows: IBVE, tBOS, toluene, ethyl acetate as an added base, and IBEA as an initiator were added sequentially to glass tube. Then an EtAlCl2 solution in toluene was added the monomer solution at 0 ºC to produce an initiating species (IBVE-HCl) quantitatively. The reaction was initiated by the addition of a prechilled SnCl4 solution in toluene into the mixture at 0 ºC. The polymerization was terminated by adding prechilled methanol containing a small amount of an aqueous ammonia solution. The reaction mixture was washed with water to remove the initiator residues. The solvent and other volatile ingredients were evaporated under reduced pressure, and then a product polymer was vacuum-dried overnight. Conversion of IBVE was determined from its residual concentration measured by gas chromatography with heptane as an internal standard. The monomer compositions of the obtained polymers were measured by 1H NMR. 1 H NMR b, c a, d e i a, d, f, g h Figure S1. 1H NMR spectra of the products in the copolymerization of IBVE and tBOS recorded in CDCl3 at 30 ºC; [IBVE]0 = 0.38 M, [tBOS]0 = 0.40 M, [IBEA]0/[EtAlCl2]0 = 4.0 mM/2.5 mM, [SnCl4]0 = 10 mM, [CH3COOEt] =1.0 M, [heptane] = 5 vol%, in toluene at 0 ºC. S3 Figure S2. MWD curves of the products in the copolymerization of IBVE and tBOS; [IBVE]0 = 0.38 M, [tBOS]0 = 0.40 M, [IBEA]0/[EtAlCl2]0 = 4.0 mM/2.5 mM, [SnCl4]0 = 10 mM, [CH3COOEt] =1.0 M, [heptane] = 5 vol%, in toluene at 0 ºC. IV. Domino Synthesis of Star-Shaped Polymers Star polymer synthesis was conducted in the same way as that for block copolymerization. IBVE, a divinyl compound (BVP, DVE, or DIPB), toluene, CH2Cl2, ethyl acetate as an added base, and IBEA as an initiator were mixed in a glass tube. To the solution an EtAlCl2 or TiCl4 solution in toluene was added at 0 ºC to produce an initiating species quantitatively. The reaction was initiated by the addition of a prechilled SnCl4 solution in toluene into the mixture at 0 ºC. The polymerization was terminated by adding prechilled methanol containing a small amount of an aqueous ammonia solution. The reaction mixture was washed with water to remove the initiator residues. The solvent and other volatile ingredients were evaporated under reduced pressure, and then a product polymer was vacuum-dried overnight. Conversion of IBVE was determined by gravimetry. S4 1 H NMR spectra Core b, c a, d e a, d, f, g, j h i Figure S3. 1H NMR spectra of poly(IBVE) (A) and star-shaped poly(IBVE) (B) recorded in CDCl3 at 30 ºC; [IBVE]0 = 0.57 M, [BVP]0 = 40 mM, [IBEA]0/[EtAlCl2]0 = 4.0 mM/2.5 mM, [SnCl4]0 = 10 mM, [CH3COOEt] =1.0 M, in toluene/CH2Cl2 (9/1 v/v) at 0 ºC. S5 1 H NMR b, c a, d, f, g, j e h i Figure S4. 1H NMR spectra of the lower molecular weight fraction products in the copolymerization of IBVE and BVP using EtAlCl2 alone recorded in CDCl3 at 30 ºC; [IBVE]0 = 0.57 M, [BVP]0 = 40 mM, [IBEA]0/[EtAlCl2]0 = 4.0 mM/20 mM, [CH3COOEt] =1.0 M, in toluene/CH2Cl2 (9/1 v/v) at 0 ºC. Figure S5. MWD of the products in the copolymerization of IBVE and BVP using EtAlCl2 alone in toluene/CH2Cl2= (9/1 v/v) at 0 ºC: RI detection ( ), UV absorption at 254 nm (- - -). VI. References (1) Ericsson, J.; Hult, A. Polym. Bull. 1987, 18, 295-302. (2) Aoshima, S.; Higashimura, T. Macromolecules 1989, 22, 1009-1013. S6