Instrumentation Design for High Energy Physics Detectors

advertisement

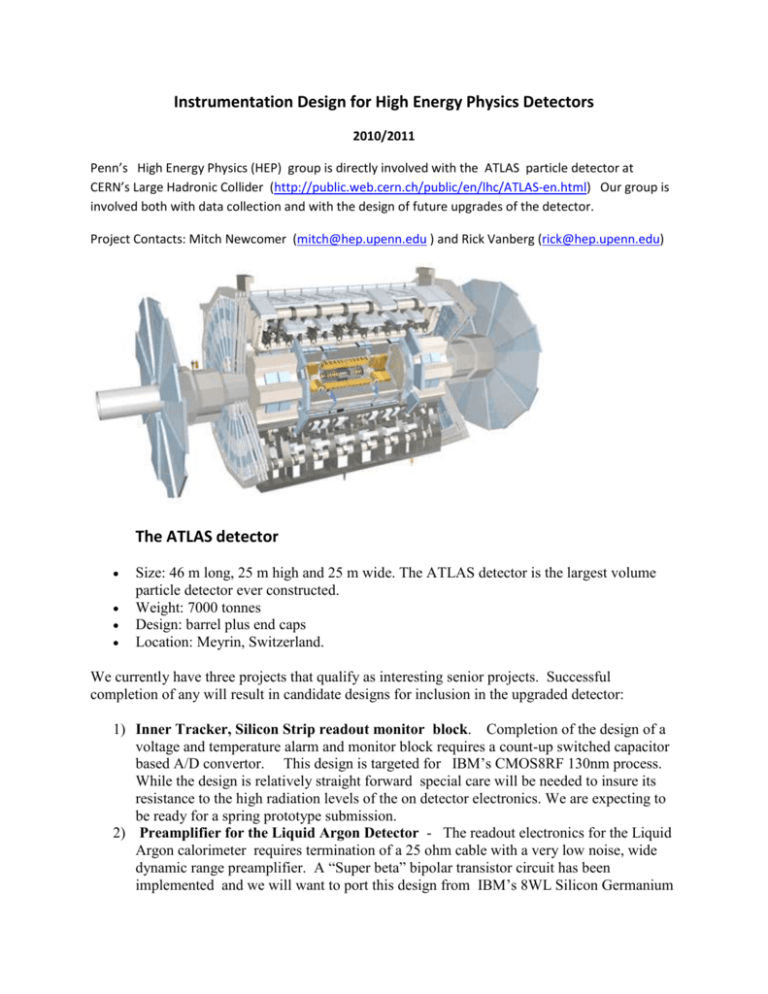

Instrumentation Design for High Energy Physics Detectors 2010/2011 Penn’s High Energy Physics (HEP) group is directly involved with the ATLAS particle detector at CERN’s Large Hadronic Collider (http://public.web.cern.ch/public/en/lhc/ATLAS-en.html) Our group is involved both with data collection and with the design of future upgrades of the detector. Project Contacts: Mitch Newcomer (mitch@hep.upenn.edu ) and Rick Vanberg (rick@hep.upenn.edu) The ATLAS detector Size: 46 m long, 25 m high and 25 m wide. The ATLAS detector is the largest volume particle detector ever constructed. Weight: 7000 tonnes Design: barrel plus end caps Location: Meyrin, Switzerland. We currently have three projects that qualify as interesting senior projects. Successful completion of any will result in candidate designs for inclusion in the upgraded detector: 1) Inner Tracker, Silicon Strip readout monitor block. Completion of the design of a voltage and temperature alarm and monitor block requires a count-up switched capacitor based A/D convertor. This design is targeted for IBM’s CMOS8RF 130nm process. While the design is relatively straight forward special care will be needed to insure its resistance to the high radiation levels of the on detector electronics. We are expecting to be ready for a spring prototype submission. 2) Preamplifier for the Liquid Argon Detector - The readout electronics for the Liquid Argon calorimeter requires termination of a 25 ohm cable with a very low noise, wide dynamic range preamplifier. A “Super beta” bipolar transistor circuit has been implemented and we will want to port this design from IBM’s 8WL Silicon Germanium BiCMOS process to the less expensive German process, IHP’s SG25H3P. Problems will include keeping the design specs of 0.25nV/rtHz noise and 5mA input dynamic range. (The preamplifier gain is specified as a trans resistance of 800 ohms). Prototype fabrication is scheduled for Spring 2011. 3) Shaper for the Liquid Argon Detector - The signals from the Liquid Argon detector require a fixed time shaping with two integrations and one differentiation, refered to as CR-(RC)2. A preliminary version was fabricated in 2008 along with the preamp mentioned above in IBM’s 8WL process. Several improvements may be possible including lowering the power by reverting to a single ended design and impoving the interface to the preamp to reduce the restrictions on the preamp output. An initial prototype of the shaper would be fabricated in the Spring of 2011. Interested persons are invited to contact Mitch Newcomer mitch@hep.upenn.edu) for additional details.