Novel polymer stabilized water soluble Ru

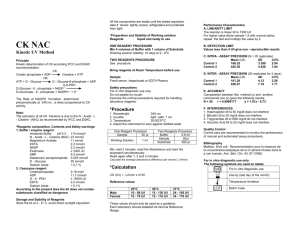

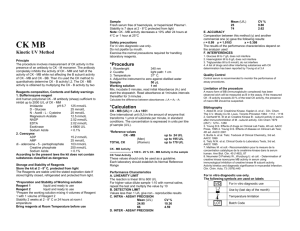

advertisement

Supporting Information Novel polymer stabilized water soluble Ru-nanoparticles as aqueous colloidal Fischer-Tropsch catalysts Aitor Gual, Jorge A. Delgado, Cyril Godard,* Sergio Castillón, Daniel Curulla-Ferré and Carmen Claver* General methods. All syntheses were performed using standard Schlenk techniques under N2 or Ar atmosphere. Solvents were purified by standard procedures. All other reagents were used as received. RuCl3.nH2O were purchased from Jonhson & Matthey. PVP K-30, Lignin type polymers and NaBH4 were purchased from Sigma-Aldrich. Hydrogen 5.0 was purchased from Air Liquide. TEM samples were prepared by slow evaporation of a drop of each colloidal solution deposited under an argon atmosphere onto a formvar carbon-covered copper grid. The TEM experiments were performed at the “Unitat de Microscopia dels Serveis Cientificotècnics de la Universitat Rovira I Virgili” (TEM-SCAN) in Tarragona with Zeiss 10 CA electron microscope operating at 100 kV with resolution of 3 Å. The particles size distributions were determined by a manual analysis of enlarged images. At least 300 particles on a given grid were measured in order to obtain a statistical size distribution and a mean diameter. General procedure for the synthesis of Ru-NPs by hydrogen reduction. As a standard procedure, the ruthenium salt was dissolved in H2O (20 mL) containing the chosen polymer in a reactor vessel. The reactor vessel was then pressurized at r.t. under dihydrogen and warmed to the desired temperature. After 2h of reaction, the hydrogen pressure was removed, and a drop of the colloidal solution was deposited under an argon atmosphere on a formvar carbon-covered copper grid for electron microscopy analysis. Ru1. The synthesis of Ru1 was completed according to the general procedure using RuCl3·nH2O (73 mg, 0.279 mmol) as metallic precursor and PVP (620 mg, 5.58 mmol) as stabilizing agent under 20 bar of hydrogen pressure at 150ºC. Mean diameter = 1.9 ± 0.5 nm. Ru2. The synthesis of Ru2 was completed according to the general procedure using RuCl3·nH2O (73 mg, 0.279 mmol) as metallic precursor and PVP (1240 mg, 11.16 mmol) as stabilizing agent under 20 bar of hydrogen pressure at 150ºC. Mean diameter = 1.9 ± 0.6 nm. Ru3. The synthesis of Ru3 was completed according to the general procedure using RuCl3·nH2O (73 mg, 0.279 mmol) as metallic precursor and PVP (6240 mg, 55.80 mmol) as stabilizing agent under 20 bar of hydrogen pressure at 150ºC. Mean diameter = 1.6 ± 0.5 nm. Ru4. The synthesis of Ru4 was completed according to the general procedure using RuCl3·nH2O (73 mg, 0.279 mmol) as metallic precursor and PVP (620 mg, 5.58 mmol) as stabilizing agent under 20 bar of hydrogen pressure at 120ºC. Mean diameter = 1.8 ± 0.5 nm. Ru5. The synthesis of Ru5 was completed according to the general procedure using RuCl3·nH2O (73 mg, 0.279 mmol) as metallic precursor and PVP (620 mg, 5.58 mmol) as stabilizing agent under 20 bar of hydrogen pressure at 60ºC. Mean diameter = 1.8 ± 0.6 nm. Ru6. The synthesis of Ru6 was completed according to the general procedure using RuCl3·nH2O (73 mg, 0.279 mmol) as metallic precursor and PVP (1240 mg, 11.16 mmol) as stabilizing agent under 20 bar of hydrogen pressure at 60ºC. Mean diameter = 1.7 ± 0.7 nm. Ru7. The synthesis of Ru7 was completed according to the general procedure using RuCl3·nH2O (37 mg, 0.140 mmol) as metallic precursor and PVP (620 mg, 5.58 mmol) as stabilizing agent under 20 bar of hydrogen pressure at 60ºC. Mean diameter = 1.8 ± 0.7 nm. Ru8. The synthesis of Ru8 was completed according to the general procedure using RuCl3·nH2O (37 mg, 0.140 mmol) as metallic precursor and PVP (3100 mg, 27.9 mmol) as stabilizing agent under 20 bar of hydrogen pressure at 60ºC. Mean diameter = 1.5 ± 0.5 nm. Ru9. The synthesis of Ru9 was completed according to the general procedure using RuCl3·nH2O (73 mg, 0.279 mmol) as metallic precursor and PVP (1240 mg, 11.16 mmol) as stabilizing agent under 10 bar of hydrogen pressure at 60ºC. Mean diameter = 1.9 ± 0.4 nm. Ru10. The synthesis of Ru10 was completed according to the general procedure using RuCl3·nH2O (73 mg, 0.279 mmol) as metallic precursor and PVP (1240 mg, 11.16 mmol) as stabilizing agent under 3 bar of hydrogen pressure at 60ºC. Mean diameter = 1.9 ± 0.5 nm. Ru11. The synthesis of Ru11 was completed according to the general procedure using RuCl3·nH2O (73 mg, 0.279 mmol) as metallic precursor and PVP (1240 mg, 11.16 mmol) as stabilizing agent under 3 bar of hydrogen pressure at 150ºC. Mean diameter = 1.9 ± 0.5 nm. Ru17. The synthesis of Ru18 was completed according to the general procedure using RuCl3·nH2O (73 mg, 0.279 mmol) as metallic precursor and Lignin 1 (920 mg, 5.58 mmol) as stabilizing agent under 20 bar of hydrogen pressure at 60ºC. Mean diameter = 1.9 ± 0.5 nm. Ru18. The synthesis of Ru19 was completed according to the general procedure using RuCl3·nH2O (73 mg, 0.279 mmol) as metallic precursor and Lignin 2 (920 mg, 5.58 mmol) as stabilizing agent under 20 bar of hydrogen pressure at 60ºC. Mean diameter = 3.7 ± 0.9 nm. Ru19. The synthesis of Ru20 was completed according to the general procedure using RuCl3·nH2O (73 mg, 0.279 mmol) as metallic precursor and Lignin 3 (920 mg, 5.58 mmol) as stabilizing agent under 20 bar of hydrogen pressure at 60ºC. Mean diameter = 5.5 ± 2.6 nm. General procedure for the synthesis of Ru-NPs by NaBH4 reduction. As a standard procedure, RuCl3.nH2O was dissolved in H2O (15 mL) containing the chosen polymer. A solution of NaBH4 (10 eq. NaBH4/ eq. metal) in 5 mL of H2O was slowly added at room temperature. The solution was maintained with a vigorous magnetic stirring for 2 h. After that period of time, a drop of the colloidal solution was deposited under an argon atmosphere on a formvar carbon-covered copper grid for electron microscopy analysis. Ru12. The synthesis of Ru12 was completed according to the general procedure using RuCl3·nH2O (73 mg, 0.279 mmol) as metallic precursor and PVP (620 mg, 5.58 mmol) as stabilizing agent. Mean diameter = 2.2 ± 0.6 nm. Ru13. The synthesis of Ru13 was completed according to the general procedure using RuCl3·nH2O (73 mg, 0.279 mmol) as metallic precursor and PVP (1240 mg, 11.16 mmol) as stabilizing agent. Mean diameter = 2.1 ± 0.6 nm. Ru14. The synthesis of Ru14 was completed according to the general procedure using RuCl3·nH2O (73 mg, 0.279 mmol) as metallic precursor and PVP (6240 mg, 55.80 mmol) as stabilizing agent. Mean diameter = 1.7 ± 0.4 nm. Ru15. The synthesis of Ru15 was completed according to the general procedure using RuCl3·nH2O (37 mg, 0.140 mmol) as metallic precursor and PVP (620 mg, 5.58 mmol) as stabilizing agent. Mean diameter = 2.0 ± 0.6 nm. Ru16. The synthesis of Ru17 was completed according to the general procedure using RuCl3·nH2O (37 mg, 0.140 mmol) as metallic precursor and PVP (3100 mg, 27.9 mmol) as stabilizing agent. Mean diameter = 1.8 ± 0.6 nm. Preparation of Ru nanoclusters Ru20 and Ru 21 from Ru2 using the seeded growth method.Error! Bookmark not defined. Preparation of Ru20. An aqueous solution (5 mL) containing Ru2 (as the seeds, 0.07 mmol of Ru) and 18.5 mg of RuCl3⋅nH2O (0.07 mmol of Ru) were diluted in 10.0 ml of deionized water while stirring. Then, the solution was placed in a reactor vessel, and reduced under 20 bar H2 at 60 °C for 2 h. Mean diameter Ru20 = 2.2 ± 0.6 nm. These RuNPs solution was used to prepare larger ones. The resulting solution was tested in the Fischer-Tropsch synthesis after the addition of 0.620 g of PVP in order to keep the PVP:Ru ratio at 40:1. Preparation of Ru21.An aqueous solution (6 mL) containing Ru20 (as the seeds, 0.153 mmol of Ru) and 18 mg of RuCl3⋅nH2O (0.07 mmol of Ru) were diluted in 9.0 ml of deionized water while stirring. Then, the solution was placed in a reactor vessel, and reduced under 20 bar H 2 at 60 °C for 2 h. Mean diameter Ru21 = 2.6 ± 0.7 nm. The resulting solution was tested in the Fischer-Tropsch synthesis after the addition of 0.900 g of PVP in order to keep the PVP:Ru ratio at 40:1 General procedure for the Fischer-Tropsch reaction using water-soluble metal nanocatalysts. For catalytic testing, a 33 mL H2O solution of the freshly prepared Ru nanoclusters (0.464 mmol metal) was placed in a 100-mL stainless steel autoclave and heated in the presence of 10 bar CO and 20 bar H2. The autoclave was kept at the desired reaction temperature (150ºC) with stirring at 1000 rpm. After reaction, the autoclave was cooled to room temperature. The gas phase was analyzed on-line by GC-TCD chromatography. The resulting liquid phase was extracted with dichloromethane (10 mL), and the organic phase was analyzed by GC-MS chromatography. The quantification of each compound was carried out using the corresponding calibration curve obtained from standard samples. Standard samples containing CO, CO2 and C1-C5 compounds were purchased from Abello-Linde. Standard samples containing n-alkanes C7-C40 were purchased from Sigma-Aldrich. The rest of the compounds were purchased individually from Sigma-Aldrich. Product analysis All the hydrocarbon products were identified by comparison with reference samples. The components contained in the gas phase (CO, H2, Ar, CO2, and C1-C8 hydrocarbons) were analysed on a Agilent 7890A GC using a system of three columns: Hayesep Q (3ft x 1/8 in), HP-Molesieve (30m x 0.320 mm x 12 µm) and HP-Plot/Q (30m x 0.320 mm x 20 µm) using helium as carrier gas. The quantification was carried out using calibration curves for each gas. Solutions at different concentration of gases were prepared by gas blending from a standard reference of gases (Avello Linde). The compounds present in the aqueous phase were extracted with dichloromethane (10 ml). The bottom organic phase containing the hydrocarbon and oxygenated products were analysed immediately by GC-MS on a 9575C MSD system using a HP-Innowax capillary column (30m x 0.250 mm x 0.15 µm), and helium as carrier gas. The identification and quantification of products was performed by comparison with standards using calibration curves for each compound. Activity and Selectivity Calculations The activity and selectivity was calculated based on the number of moles of carbon being formed as products according to the following formulas: Activity = mol of CO converted in products mol of Ru ∗ reaction time (h) Activity = weigth of CO converted in products weigth of Ru ∗ reaction time (h) Selectivity Cn = weigth of 𝐶𝑛 total weigth of products XPS characterization of Ru1 and Ru12 b a C1s; Ru3d 3/2 C1s 282.83 O1s 1 Na1s Cl2s 1000 800 600 400 Binding energy (eV) B1s 200 Intensity (a.u.) Intensity (a.u.) N1s 1 283.64 2 2 0 292 288 284 Binding energy (eV) Figure 1S. (a) Full XPS and (b) Ru 3d XPS spectra of RuNPs (1) Ru1 (2) Ru12 280 276 XRD characterization of Ru1 and Ru12 counts (a.u.) 1 2 30 40 50 60 70 2 () Figure 2S. (a) XRD patterns of RuNPs (1) Ru1 (2) Ru12