Contribute to OHS Processes - E-Learning for Participation & Skills

AHCOHS301A - Contribute to OHS Processes

GREAT SOUTHERN INSTITUTE OF TECHNOLOGY

AHCOHS301A - Contribute to OHS Processes

AHCOHS301A - Contribute to OHS Processes

This document has been created for trainers by trainers with financial assistance from the National VET E-Learning Strategy. The content has been developed and presented with respect to the required elements of the unit and follows the required outcomes of the training package. Any lecturer or trainer is able to use all or any of the following content for their own training needs or modify all or any of the content for their training needs. All images may be used by the trainer or they may substitute for their own as needed.

For more information or clarification, please contact Andrew Morrison at the Great Southern Institute of Technology (Albany, Western Australia) by emailing andrew.morrison@gsit.wa.edu.au (Project Manager).

Page 1 of 60

AHCOHS301A - Contribute to OHS Processes

TABLE OF CONTENTS

Page 2 of 60

AHCOHS301A - Contribute to OHS Processes

Element 1.1

Module Information

Developers

Competency

Element

Criteria

Applied Quality Training Fundamentals (AQTF)

This unit covers the process of carrying out enterprise Occupational Health and Safety (OHS) policies and procedures and defines the standard required to:

work in accordance with workplace procedures in hazard identification and risk control

carry out safe practices during work operations

participate in arrangements for maintaining the health and safety of all people in the workplace

1 Adapt OHS policies and procedures

Criteria 1: Information regarding the organisation OHS policies and procedures is made readily accessible to all employees

Page 3 of 60

AHCOHS301A - Contribute to OHS Processes

Importance of health and safety

Written Content

Linked Resources

Everyone in the workplace needs to understand the importance of health and safety, what their part is in making the workplace safer and how they can fulfil their responsibilities/obligations and duties under federal(Commonwealth) OHS legislation and the

OHS legislation relevant to their state or territory.

To work efficiently and safely in your workplace, you must work in agreement with all:

Occupational health and safety (OHS) legislation

Standards and regulations

Codes of practice/compliance codes

Policies and procedures

Workers can contribute to safety in the workplace by identifying hazards, assessing risk, making changes to address an identified hazard, evaluating the action taken and regularly reviewing the entire process to ensure the hazard is controlled or eliminated.

AHCLPW306A_Equipment.pdf

Images

Caption: OHS Legislation

Page 4 of 60

Assessment

Question

Answer

AHCOHS301A - Contribute to OHS Processes

Question No 1 English

Workers can contribute to safety in the workplace by identifying hazards, assessing risk, making changes to address an identified hazard

1.

True

2.

False

True

Page 5 of 60

AHCOHS301A - Contribute to OHS Processes

Element 1.2

Module Information

Developers

Competency

Element

Criteria

Applied Quality Training Fundamentals (AQTF)

This unit covers the process of carrying out enterprise Occupational Health and Safety (OHS) policies and procedures and defines the standard required to:

work in accordance with workplace procedures in hazard identification and risk control

carry out safe practices during work operations

participate in arrangements for maintaining the health and safety of all people in the workplace

1 Adapt OHS policies and procedures

Criteria 2: Employee responsibilities prescribed in OHS legislation, codes and national standards are identified and carried out

Page 6 of 60

Employee Responsibilities

Written Content

Recognising Employee Responsibilities for OH&S

All employers are required to provide a safe workplace. OH&S legislation requires employers to:

Provide for the health, safety and welfare of everyone in the workplace

Protect persons from risks to their health and safety

Eliminate potential risks within the workplace

Involve employees in the formulation and implementation of safety standards

Employees also have responsibilities in the workplace.

OH&S legislation requires you to: Take reasonable care for your health and safety

Have due regard for the health and safety of others in the workplace

Cooperate with your employer in implementing appropriate health and safety measures

Avoid doing anything that might compromise the health and safety of others Complying with Employee

Responsibilities for OH&S

To comply with employee legislative requirements an employee must:

Take care of own health and safety

Care for the health and safety of others

Co-operate with the employer for safety

Use and maintain required Personal Protective Equipment (PPE)

Follow enterprise Standard Operating Procedures (SOPs)

Report unsafe procedures and equipment

Must not proceed without training

Images

AHCOHS301A - Contribute to OHS Processes

Caption : WA OHS Work Safe

Page 7 of 60

Assessment

Question

Answer

Assessment

Question

Answers

Assessment

Question

Answers

AHCOHS301A - Contribute to OHS Processes

Question No 1

Under the OH&S Act, employees are responsible for: (Select one or more alternatives)

1.

Collecting safety information for use in their workplace

2.

Providing items of PPE which are required for their workplace

3.

Developing standard Operating procedures for the tasks they perform

4.

Taking reasonable care of his or her own health and safety

4

English

Question No 2

Under the OH&S Act, employees are responsible for: (Select one or more alternatives)

1.

Appointing staff to manage safety in the workplace

2.

Ensuring that each employee cares for their own health and safety

3.

Ensuing that damages items of equipment are reported to work cover

4.

Providing a safe work environment

4

English

Question No 3 English

If an employee can see that a workmate is not wearing hearing protection operating a noisy machine then the employee is required to point out the risk and offer hearing protection to the workmate.

True

False

True

Page 8 of 60

AHCOHS301A - Contribute to OHS Processes

Element 1.3

Module Information

Developers

Competency

Element

Criteria

Applied Quality Training Fundamentals (AQTF)

This unit covers the process of carrying out enterprise Occupational Health and Safety (OHS) policies and procedures and defines the standard required to:

work in accordance with workplace procedures in hazard identification and risk control

carry out safe practices during work operations

participate in arrangements for maintaining the health and safety of all people in the workplace

1 Adapt OHS policies and procedures

Criteria 3: Employee responsibilities prescribed in enterprise OHS policies and procedures (including emergency procedures) are identified and carried out

Page 9 of 60

AHCOHS301A - Contribute to OHS Processes

Occupational Health and Safety Regulation 1996

Written Content

Employers need to establish plans and procedures to cope with fire and other emergencies. Emergencies can result from events such as leaks or spills, fire or explosions, mechanical failures or other incident.

Legislation which deals with this is contained in the Occupational Health and Safety Regulation 1996

Regulation 3.7 Access to and egress from workplace, duties of employer

Regulation 3.8 Emergency egress from workplace, duty of employer

Regulation 3.9 Fire precautions, duties of employer

Regulation 3.10 Evacuation procedure, duties of employer

Images

Caption: Evacuation Procedures

Page 10 of 60

Emergency plans

Written Content

AHCOHS301A - Contribute to OHS Processes

Emergency plans should include:

warning, alarm and sprinkler systems

first aid facilities

available and location of emergency equipment

accessibility of lists of emergency organisations with contact details, key personnel with their contact details and responsibilities

The purpose of an emergency plan is to:

provide written and clearly displayed procedures to be followed in the event of emergency evacuation

give specific duties to individual staff members

Images

Caption: Fire Extinguisher

Page 11 of 60

Assessment

Question

Answer

Assessment

Question

Answer

AHCOHS301A - Contribute to OHS Processes

Question No 1 English

Employers need to establish plans and procedures to cope with fire and other emergencies. Emergencies can result from events such as leaks or spills, fire or explosions, mechanical failures or other incident.

True

False

True

Question No 2 English

Emergency plans should include:(Select one or more alternatives)

1.

warning, alarm and sprinkler systems

2.

first aid facilities

3.

available and location of emergency equipment

4.

accessibility of lists of emergency organisations with contact details, key personnel with their contact details and responsibilities

1,2,3,4

Page 12 of 60

AHCOHS301A - Contribute to OHS Processes

Element 2.1

Module Information

Developers

Competency

Element

Criteria

Applied Quality Training Fundamentals (AQTF)

This unit covers the process of carrying out enterprise Occupational Health and Safety (OHS) policies and procedures and defines the standard required to:

work in accordance with workplace procedures in hazard identification and risk control

carry out safe practices during work operations

participate in arrangements for maintaining the health and safety of all people in the workplace

2Assist in workplace hazard identification and risk control

Criteria 1: Information regarding hazard identification and risk control is provided and explained regularly

Page 13 of 60

Hazard identification

Written Content

Images

AHCOHS301A - Contribute to OHS Processes

Hazard identification and risk control process is known as hazard identification. A hazard is anything with the potential to harm life, health or property.

All the types of potential hazards present in a particular job or task need to be considered and the risks presented by these hazards need to be assessed to work out how likely they are to cause harm, and how serious the harm might be.

Hazards arise from:

• The work environment

•

•

•

The use of machinery and substances

Poor work design

Inappropriate systems and procedures.

Caption: Potential Hazard

Page 14 of 60

Types of Hazards

Written Content

AHCOHS301A - Contribute to OHS Processes

Chemical hazards are substances that can harm people’s health when they are breathed in or absorbed through the skin, or when they irritate the skin. Examples include some kinds of dusts, vapours and fumes.

Physical hazards include electricity, noise, temperature, lighting, radiation and vibration.

Biological hazards such as infectious diseases can also be present in workplaces.

Manual handling can cause back injuries and other strain or sprain injuries

Psychological stress can result from workplace violence, bullying, threats or intimidation.

Employers need to recognise of any kind of hazards exist in the workplace, and to do this they should consult workers, to find out employees views of any threats to their health or safety. Employees need to be able to contribute to this process by telling their supervisor of any possible health and safety problems they find.

Images

Caption: Spill Kit for Chemical Spills

Page 15 of 60

AHCOHS301A - Contribute to OHS Processes

Identifying hazards in the Horticulture environment

Written Content

OHS risk analysis consists of hazard identification, workplace assessment and risk control. Hazards are the main identifiable cause of workplace health and safety problems. They can consist of:

•

• machinery chemicals

•

•

•

• noise electrical hazards poor work design poor management systems and procedures

• Human behaviour.

Once a hazard has been found it is then assessed as to its potential to cause damage and then a solution to the problem is sought.

Images

Caption: Poor management of a chemical spill

Page 16 of 60

Assessment

Question

Answer

Assessment

Question

Answer

Assessment

Question

Answer

AHCOHS301A - Contribute to OHS Processes

Question No 1 English

Hazards are the main identifiable causeof workplace health and safety problems. They can consist of:

1.

machinery

2.

electrical hazards

3.

poor management systems and procedures

4.

Human behaviour.

1,2,3,4

Question No 2

Physical hazards include electricity, noise, temperature, lighting, radiation and vibration

True

False true

English

Question No 3 English

Which of the following statements are true? (Select one or more alternatives)

1.

All the types of potential hazards present in a particular job or task need to be considered and the risks presented by these hazards need to be assessed to work out how likely they are to cause harm, and how serious the harm might be

2.

A hazard is anything with the potential to harm life, health or property.

1,2,

3.

OHS risk analysis consists of correctly adjusting the seat before operating a tractor.

4.

Employers need to recognise of any kind of hazards that exist in the workplace, and not consult workers

Page 17 of 60

AHCOHS301A - Contribute to OHS Processes

Element 2.3, 2.4, 2.5, 2.6

Module Information

Developers

Applied Quality Training Fundamentals (AQTF)

Competency

Element

This unit covers the process of carrying out enterprise Occupational Health and Safety (OHS) policies and procedures and defines the standard required to:

work in accordance with workplace procedures in hazard identification and risk control

carry out safe practices during work operations

participate in arrangements for maintaining the health and safety of all people in the workplace

2 Assist in workplace hazard identification and risk control

Criteria

Criteria 2: Hazards in the workplace are recognised and reported to designated personnel according to enterprise procedures

Criteria 3: Assessment of risk associated with identified hazards is made in accordance with enterprise procedures

Criteria 4: Workplace procedures and work instructions for controlling risks are followed accurately

Criteria 5: Risks to fellow workers, other people and animals are recognised and action is taken to eliminate or reduce them

Criteria 6: Safety training is undertaken or provided as necessary

Page 18 of 60

AHCOHS301A - Contribute to OHS Processes

Hazards in the workplace are recognised and reported

Written Content Responsibilities

OSH Act, section 33.1 states the Safety and Health Representatives may inspect the workplace every 30 days upon giving reasonable notice to the employer. An inspection schedule is to be developed by the OSH coordinator to program formal inspections for the calendar year. The inspection schedules should be made available on a OSH Calendar or OSH notice boards.

Management - Managers and Supervisors are responsible for ensuring that workplace inspections are carried out as required by the level of risk associated with in the area and corrective actions implemented. Employees carrying out workplace inspections are to be trained and may be assisted by the Safety and Health Representatives.

OSH Representative -OSH Representatives can inspect the workplace immediately if there is an incident or a serious risk with in the area. OSH Representatives can inspect any part of the workplace where a member of their designated work group works

OSH Coordinator - The OSH Coordinator is responsible for the development of inspection checklist and other related documents in conjunction with verifying the implementation of the OSH Workplace safety inspection

Inspection Team The inspection team are required to conduct workplace safety inspections and findings as set out in this document and to ensure hazards are controlled with the hierarchy of controls in accordance with risk control guiding principles

Page 19 of 60

Images

Caption: Chain of command

AHCOHS301A - Contribute to OHS Processes

Page 20 of 60

AHCOHS301A - Contribute to OHS Processes

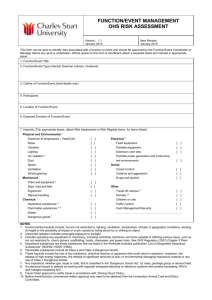

Workplace safety inspections

Written Content

Workplace safety inspections are a planned systematic approach for the identification and control of hazards and risks in the work area. Once a hazard has been identified it can be controlled by using the hierarchy of controls to control the hazard or prevent an injury from occurring.

1.

Eliminate - removing the hazard, eg taking a hazardous piece of equipment out of service.

2.

Substitute- Replacing a hazardous substance or process with a less hazardous one, eg substituting a hazardous substance with a non-hazardous substance.

3.

Isolation- Isolating the hazard from the person at risk, eg using a guard or barrier.

4.

Engineering- Redesign a process or piece of equipment to make it less hazardous.

5.

Administrative-Adopting safe work practices or providing appropriate training, instruction or information.

6.

Personal Protective Equipment-The use of personal protective equipment could include using gloves, glasses, earmuffs, aprons, safety footwear and dust masks.

Images

Caption: Work Shop Inspection Sheet

Page 21 of 60

AHCOHS301A - Contribute to OHS Processes

Assessment of risk associated with identified hazards

Written Content

Part of the procedure of recognising and controlling hazards depends on finding out what you can do and how likely it is that someone could be harmed, how serious the injury or illness may be, and how the hazard can be measured. Review any available information about the hazard, such as:

Information provided by the manufacturer of the product or equipment

Material Safety Data Sheets (MSDS)

Controlled Products – Workplace Hazardous Materials Information System(Occupational Safety and Health Regulations

1996 Chapter 22)

WorkSafe Western Australia will help you assess potential risks for particular hazards, processes and work tasks

Australian Standards that set out specifications for a range of equipment, products and materials

Codes of Practice to give you direction and guidance on the identification and control of specific hazards.

Images

Caption: Material Safety Data Sheet folder

Page 22 of 60

What is an MSDS?(TAB)

Written Content

Source Information

AHCOHS301A - Contribute to OHS Processes

An MSDS is a document containing important information about a hazardous chemical (which may be a hazardous substance and/or dangerous good) and must state:

a hazardous substance's product name

the chemical and generic name of certain ingredients

the chemical and physical properties of the hazardous substance

health hazard information

precautions for safe use and handling

the manufacturer's or importer's name, Australian address and telephone number. http://www.deir.qld.gov.au/workplace/subjects/hazardousmaterials/definition/msds/index.htm

Page 23 of 60

AHCOHS301A - Contribute to OHS Processes

Images

Caption: Material Safety Data sheet

Page 24 of 60

Safety training

Written Content

AHCOHS301A - Contribute to OHS Processes

Occupational Health and Safety Act the employer must provide adequate information, instruction, training and supervision to employees so that they can work in a way that is safe and without risks to health.

The employer should ensure that all new workers - whether newly employed or new to the work site - are provided with training, sometimes referred to as 'Induction Training'.

Topics which need to go into a general OHS induction

OHS Legislation: Overview of the OHS Act, including duties of all parties; consultative arrangements (the OHS reps and the committees); key regulations and codes of practice (those which are most relevant for your workplace)

workplace policies and procedures (including the bullying/harassment policy; procedures to report hazards, incidents, injuries, and near misses; equal opportunity; hazardous substances; etc)

what are the Designated Work Groups and who the OHS reps are

major potential hazards in the workplace, potential effects, how to identify them, and how they are controlled in the workplace

first aid arrangements, including who the first aiders are

emergency evacuation procedures

brief workers' comp and rehab rights

Each worker will require training specific to their job to ensure that they can do the job in a healthy and safe manner and know all the relevant procedures and so on.

Images

Caption: First Aid Station

Page 25 of 60

AHCOHS301A - Contribute to OHS Processes

The hazard identification and risk control process

Written Content

The hazard identification and risk control process can be simple or complex, depending on the scope and nature of the risks to health and safety.

The principles, however, remain the same. Risks need to be:

identified (using records of injury, illness, incidents, talking to workers, workplace inspections, audits, surveys or accident investigations)

assessed (risks are checked out for the likelihood and severity of possible harm, and ranked in priority order)

controlled (effective ways to control the risk are identified then put into practice, using the hierarchy of risk controls)

Evaluated and reviewed (new risks need to be checked for, and methods of risk control need to be checked to see whether they are accomplishing their purpose adequately, and not creating new risks).

Workers need to follow organisational procedures and instructions for risk control when hazards are present. Complying with safety signs is part of risk control.

Page 26 of 60

AHCOHS301A - Contribute to OHS Processes

Images

Caption: Who are your safety officers?

Page 27 of 60

Answer

Assessment

Question

Answer

Assessment

Question

Assessment

Question

Answer

AHCOHS301A - Contribute to OHS Processes

Question No 1 English

The hazard identification and risk control process can be simple or complexhowever the principles remain the same. (Select one or more alternatives)

Risks need to be:

1.

Ignored when you are under time pressure

2.

Taken in order to be efficient

3.

Controlled by the supervisor only

4.

Evaluated and reviewed

4

Question No 2 English

Under the Occupational Health and Safety Act the employer must provide adequate information, instruction, training and supervision to employees so that they can work in a way that is safe and without risks to health.

True

False

True

Question No 3 English

An MSDS is a document containing important information about a hazardous chemical, it should contain (Select one or more alternatives)

1.

A hazardous substance's common name

2.

What the hazardous substance tastes like

3.

The chemical and physical properties of the hazardous substance

4.

Health hazard information

5.

The manufacturer's or importer's name, Australian address and telephone number.

3,4,5

Page 28 of 60

AHCOHS301A - Contribute to OHS Processes

Element 3.1

Module Information

Developers

Competency

Element

Criteria

Applied Quality Training Fundamentals (AQTF)

This unit covers the process of carrying out enterprise Occupational Health and Safety (OHS) policies and procedures and defines the standard required to:

work in accordance with workplace procedures in hazard identification and risk control

carry out safe practices during work operations

participate in arrangements for maintaining the health and safety of all people in the workplace

3 Observe safe practices during work operations

Criteria 1: Personal Protective Equipment (PPE) required for work is identified, used, maintained and stored according to enterprise procedures

Page 29 of 60

AHCOHS301A - Contribute to OHS Processes

Personal Protective Equipment

Written Content

Page No: 2

PPE stands for Personal Protective Equipment which means special clothing and other equipment designed to protect workers from injuries caused by hazards in the workplace. Where the industry or business requires this equipment to be worn it MUST be worn by the employee. The employee has a duty of care to abide by the rules of the organisation. PPE is used in many places, for example, outside maintenance or gardening contractors, roadside workers, truck drivers, laboratory workers, and workers who work with dangerous chemicals or substances.

Images

Caption: Personal Protective Equipment Shed

Page 30 of 60

Symbols and Signs

Written Content

AHCOHS301A - Contribute to OHS Processes

Some companies use safety signs and symbols to indicate the hazards present in various parts of the work environment. These are standard international signs from which workers can tell, eg where eye protection should be worn, or where emergency showers are located. Workers should be familiar with these signs and comply with them at all times.

Images

Caption: Safety Signs and Symbols - Emergency Shower and Chemical Storage Area

Page 31 of 60

Assessment

Question

Answer

Question No 1

PPE stands for:(Select one alternative)

1.

Personal Protective Equipment

2.

Personal Produce Equal

3.

Pears produce Enzymes

1

English

AHCOHS301A - Contribute to OHS Processes

Page 32 of 60

AHCOHS301A - Contribute to OHS Processes

Element 3.2

Module Information

Developers

Competency

Element

Criteria

Applied Quality Training Fundamentals (AQTF)

This unit covers the process of carrying out enterprise Occupational Health and Safety (OHS) policies and procedures and defines the standard required to:

work in accordance with workplace procedures in hazard identification and risk control

carry out safe practices during work operations

participate in arrangements for maintaining the health and safety of all people in the workplace

3 Observe safe practices during work operations

Criteria 2: Basic safety checks on all machinery and equipment are undertaken before operation according to enterprise procedures

Page 33 of 60

AHCOHS301A - Contribute to OHS Processes

Mechanical equipment

Written Content

Mechanical equipment can cause serious injuries that include sprains and strains, open wounds, fractures and amputations. Some injuries can even be fatal. The most frequent injuries from mechanical equipment are to hands and fingers. Eye injuries are also common.

You should not use mechanical equipment if it is:

• not designed to be safe

• not well made

• not properly guarded

• not well maintained

• going to be used to do something other than what it was designed for

• going to be used in different conditions

• has been illegally modified or changed.

Before operating mechanical equipment you need to be trained in its safe use. Mechanical equipment should not be used in circumstances where you are unable to pay attention to the task.

Images

Caption: Read manual first before operating any machinery

Page 34 of 60

Tags

Written Content

AHCOHS301A - Contribute to OHS Processes

Three important procedures used for mechanical equipment are:

Yellow and black Out of Service tags are used to prevent accidents or damage to machinery that is out of service for repairs, for example a drill that has an electrical fault.

Red and black Danger tags are used to warn workers about hazards associated with equipment and machinery maintenance.

Locking out of equipment – this procedure prevents the equipment from being operated during maintenance by putting a lock on the switch so it cannot be turned on. The person working on the machine should hold the only key to the lock.

Images

Caption: Yellow and black Out of Service tags are used to prevent accidents or damage to machinery.

Page 35 of 60

Standard Operating Procedures

Written Content

Standard Operating Procedures (SOPS) are a set of fixed instructions or steps for carrying out routine operations.

SOPS should show

pre-operational safety checks

operational safety checks

housekeeping

potential hazards

personal protective equipment

Images

AHCOHS301A - Contribute to OHS Processes

Caption: Safety Operating Procedures should be easy accessed and followed.

Page 36 of 60

Answer

Assessment

Question

Answer

Assessment

Question

Answer

Assessment

Question

Answer

Assessment

Question

AHCOHS301A - Contribute to OHS Processes

Question No 1 English

It is appropriate to use mechanical equipment if the guard has been removed for cleaning because it will not be off for very long

True

False

False

Question No 2 English

Which of the following statements are true: (Select one or more alternatives)

1.

Only experienced operators should use unsafe mechanical equipment.

2.

If you are asked to use a machine that has been modified but you think may be unsafe you must do as you are told.

3.

Inexperienced operators should use the oldest machines in case they damage the new ones

4.

There is no need for experienced operators to do pre operational checks

5.

Machinery with a Red and black Danger tag should not be used

5

Question No 3 English

If you are experienced in using a piece of mechanical equipment, you do not need to pay as much attention as someone who is new to using it.

True

False

False

Question No 4 English

An ‘Out of Service’ tag means it’s alright to use the equipment but not very often, and you need to be extra careful.

True

False

False

Page 37 of 60

AHCOHS301A - Contribute to OHS Processes

Element 3.3

Module Information

Developers

Competency

Element

Criteria

Applied Quality Training Fundamentals (AQTF)

This unit covers the process of carrying out enterprise Occupational Health and Safety (OHS) policies and procedures and defines the standard required to:

work in accordance with workplace procedures in hazard identification and risk control

carry out safe practices during work operations

participate in arrangements for maintaining the health and safety of all people in the workplace

3 Observe safe practices during work operations

Criteria 3:Hazards associated with handling of hazardous substances are identified, risks assessed and risk controls implemented in accordance with enterprise procedures and OHS requirements

Page 38 of 60

AHCOHS301A - Contribute to OHS Processes

Hazardous substances

Written Content

Many chemicals used in the workplace can be dangerous to your health. These are called hazardous substances. A place of work may use many different hazardous substances. Some may be familiar to you, and might even be everyday chemicals such as cement, cleaning liquids and powders.

How dangerous a hazardous substance is depends on the type of substance it is, how it enters the body, and the amount of substance that enters.

Hazardous substances enter the body in three main ways:

breathing in

swallowing (e.g. eating or smoking with contaminated hands)

Skin contact.

The effects of exposure to hazardous substance can transpire suddenly e.g. dizziness, nausea, itchy eyes and burns. Harm can also happen over a number of years (such as dermatitis or cancer).

Images

Caption: Avoid skin contact chose the Gloves for the purpose

Page 39 of 60

Hazardous substances

Written Content

AHCOHS301A - Contribute to OHS Processes

There are two elementary sources for identifying the risks from a hazardous substance:

• Reading the label

• Reading the Material Data Safety Sheet (MSDS).

The use of hazardous substances should be removed where possible. If this cannot be done then the substance should be replaced for something that is less harmful. If this cannot be done efforts should be made to segregate the work area, and introduce engineering controls like fans and compartments to limit exposure to people.

The use of personal protective equipment such as gloves, coats, masks, and safety glasses may be used as back up controls.

Volunteering Australia

Source Information

Images

Caption: Identify the hazards

Page 40 of 60

Assessment

Question

Answer

Assessment

Question

Answer

Assessment

Question

Answer

Assessment

Question

Answer

AHCOHS301A - Contribute to OHS Processes

Question No 1

It is all right to eat your lunch in the area where you use hazardous substances

True

False

False

English

Question No 2 English

Reading the label and the MSDS can help you tell how a hazardous substance may cause you harm

True

False

True

Question No 3 English

Which of the following statements are correct? (Select one or more alternatives)

1.

A place of work may use many different hazardous substances.

2.

Everyday chemicals such as cement, cleaning liquids and powders are not hazardous substances.

3.

How dangerous a hazardous substance is has no bearing on the type of substance it is or how it enters the body.

4.

Safety directions for the use of any product are written on the label.

1 4

Question No 4 English

Reading the label and the MSDS will provide information on what to do should you suspect unsafe exposure to the substance has occurred.

True

False

True

Page 41 of 60

AHCOHS301A - Contribute to OHS Processes

Element 3.4

Module Information

Developers

Competency

Element

Criteria

Screens within Criteria

Assessment Questions

Other

Applied Quality Training Fundamentals (AQTF)

This unit covers the process of carrying out enterprise Occupational Health and Safety (OHS) policies and procedures and defines the standard required to:

work in accordance with workplace procedures in hazard identification and risk control

carry out safe practices during work operations

participate in arrangements for maintaining the health and safety of all people in the workplace

3 Observe safe practices during work operations

Criteria 4: Noise hazards are identified and notified, risks assessed and risk controls implemented in accordance with enterprise procedures and OHS requirements

Page 42 of 60

Noise

Written Content

Source Information

Images

AHCOHS301A - Contribute to OHS Processes

Excessive noise destroys delicate nerve cells in the inner ear that transmit sound messages to the brain resulting in lasting hearing loss. Some early warning signs of hearing loss include:

• ringing in the ears after a noisy activity

• difficulty in understanding what people say

• failing to hear noises like the telephone ringing or the doorbell

• having to turn up the television or radio when others seem to hear it

• things sounding different after noise exposure.

Volunteering Australia

Caption: Select the Ear Protection which best suits the task undertaken

Page 43 of 60

Noise

Written Content

Source Information

Images

AHCOHS301A - Contribute to OHS Processes

The best way to tell if a noise is harmful is for a trained person to measure it.

However as a general rule if you need to increase your voice to make yourself heard a metre away, your hearing is at risk.

Where noise is a problem every effort should be made to quieten the source of the noise, by eliminating it or altering the design.

If this cannot be done then efforts should be made to try to prevent the noise from reaching people. This might include moving the source of the noise away from people or putting up a barrier between them.

Hearing protection can also be used, but this should only be a temporary measure or as a last resort.

Volunteering Australia

Caption: moving the source of the noise away from people

Page 44 of 60

Assessment

Question

Answer

Assessment

Question

Answer

AHCOHS301A - Contribute to OHS Processes

Question No 1 English

Which of the following statements are incorrect? (Select one or more alternatives)

1.

If you hear ringing in your ears after doing a noisy job there is no need to tell anyone because it will go away after a while

2.

Excessive noise destroys delicate nerve cells in the inner ear that transmit sound messages to the brain resulting in lasting hearing loss.

3.

You are operating in a normal situation if you need to increase your voice to make yourself heard a metre away.

4.

Moving the source of noise has little or no impact on people working in the area.

1 3 4

English Question No 2

Excessive noise can cause permanent hearing loss

True

False

True

Page 45 of 60

AHCOHS301A - Contribute to OHS Processes

Element 3.5

Module Information

Developers

Competency

Element

Criteria

Screens within Criteria

Assessment Questions

Other

Applied Quality Training Fundamentals (AQTF)

This unit covers the process of carrying out enterprise Occupational Health and Safety (OHS) policies and procedures and defines the standard required to:

work in accordance with workplace procedures in hazard identification and risk control

carry out safe practices during work operations

participate in arrangements for maintaining the health and safety of all people in the workplace

3 Observe safe practices during work operations

Criteria 5: Manual handling risks are assessed prior to activity, and safe lifting practices are used

Page 46 of 60

Manual handling

Written Content

Source Information

Images

AHCOHS301A - Contribute to OHS Processes

Manual handling is any activity that involves lifting, lowering, pushing, pulling, carrying, moving, holding or restraining an object, animal or person.

Unsafe manual handling activities can cause injuries that include:

• strain and sprains

• neck and back injuries

• slips, trips, falls and crush incidents

• cuts, bruises and broken bones

• Occupational overuse syndrome (OOS), also known as RSI (repetitive strain injury).

Volunteering Australia

Caption: Make sure you lift correctly to prevent any injury to yourself

Page 47 of 60

AHCOHS301A - Contribute to OHS Processes

Manual handling injuries

Written Content

Source Information

Some examples of actions that may cause manual handling injuries are:

• work involving sudden, jerky or hard to control movements

• too much bending, reaching or twisting

• work where a long time is spent holding the same position or posture

Where manual handling is a problem the best way to reduce the risk of injury is to remove the activity altogether. If this cannot be done efforts should be made to restructure the task or work area to make it safer.

Training staff in proper lifting techniques, and making changes to the work environment such as improving lighting, controlling temperature and keeping areas free of clutter can also be useful

Volunteering Australia

Images

Caption: Correct Lifting Techniques

Page 48 of 60

Assessment

Question

Answer

Assessment

Question

Answer

Question No 1

Unsafe manual handling activities can cause strains and sprains

True

False

True

Question No 2

Taking regular breaks can help reduce the risk of some manual handling injuries.

True

False

True

English

English

AHCOHS301A - Contribute to OHS Processes

Page 49 of 60

AHCOHS301A - Contribute to OHS Processes

Element 3.6

Module Information

Developers

Competency

Element

Criteria

Screens within Criteria

Assessment Questions

Other

Applied Quality Training Fundamentals (AQTF)

This unit covers the process of carrying out enterprise Occupational Health and Safety (OHS) policies and procedures and defines the standard required to:

work in accordance with workplace procedures in hazard identification and risk control

carry out safe practices during work operations

participate in arrangements for maintaining the health and safety of all people in the workplace

3 Observe safe practices during work operations

Criteria 6: Information on OHS for specific work operations is accessed as required

Page 50 of 60

OHS instructions

Written Content

AHCOHS301A - Contribute to OHS Processes

You are likely to find OHS instructions:

• written down in a safety manual, or in the organisation’s policies

• told to you verbally by someone like your supervisor, a health and safety representative, responsible co-worker, manager or government inspector

• displayed in your work area as an information sheet, poster or notices.

A very common OHS instruction is the safety sign. You will find safety signs in many work areas. It is important that you know why a sign is displayed and what it is trying to tell you.

Images

Caption: Signs are very important for safety in the work place

Page 51 of 60

OHS

Written Content

OHS instructions are general safety rules that cannot be described as a policy or procedure.

OHS instructions might be for:

• taking regular breaks

• wearing protective equipment

• using equipment and machinery correctly

• lifting techniques

• taking part in regular emergency drills.

Images

AHCOHS301A - Contribute to OHS Processes

Page No: 3

Caption: Personal Protective equipment Shed

Page 52 of 60

Assessment

Question

Answer

Assessment

Question

Answer

Question No 1

OHS instructions might be: (Select one or more alternatives)

1.

Taking regular breaks

2.

Eating a snack

3.

Using PPE

4.

Lifting techniques

1,3,4

English

Question No 1

Which of the following are forms of safety instruction? (Select one or more alternatives)

1.

The safety sign

2.

A copy of your award wage agreement.

3.

The business mission statement

4.

Information written down in a safety manual, or in the organisation’s policies

5.

Information told to you verbally by someone like your supervisor, or co-worker.

6.

An information sheet, poster or notices displayed in your work area.

1 4 5 6

English

AHCOHS301A - Contribute to OHS Processes

Page 53 of 60

AHCOHS301A - Contribute to OHS Processes

Element 4.1, 4.2, 4.3, 4.4

Module Information

Developers

Applied Quality Training Fundamentals (AQTF)

Competency

Element

This unit covers the process of carrying out enterprise Occupational Health and Safety (OHS) policies and procedures and defines the standard required to:

work in accordance with workplace procedures in hazard identification and risk control

carry out safe practices during work operations

participate in arrangements for maintaining the health and safety of all people in the workplace

4 Participate in arrangements for maintaining health and safety of all people in the workplace

Criteria

Screens within Criteria

Criteria 1: Individuals have input into ongoing monitoring and reporting on all aspects of workplace safety

Criteria 2:OHS issues are raised with designated personnel in accordance with enterprise procedures and relevant OHS legislation

Criteria 3: Contributions to participative arrangements in the workplace are made within organisational procedures and scope of responsibilities and competencies

Criteria 4: Suggestions are made to assist the development of effective solutions to control the level of risk with enterprise activities

Assessment Questions

Other

Page 54 of 60

OH&S policy

Written Content

Images

AHCOHS301A - Contribute to OHS Processes

An OH&S policy is an important tool for communicating your organisation’s commitment to the safety of employees and others in the workplace. The policy in itself does not ensure safety, however it is the ‘umbrella’ document that offers direction and guidance to all in the place of work concerning how health and safety standards will be established and maintained.

Caption: OH&S Policy Handbook

Page 55 of 60

Contribute to OHS in the workplace

Written Content

Images

There are a number of ways you can contribute to a safer workplace, which include:

• understanding how OHS consultation and communication should be managed in the workplace

• improving your communication skills

• making sure that you understand the safety rules in your workplace

• making suggestions to keep the workplace safe

• attending OHS meetings

• participating in emergency drills and safety training

• completing safety checklists.

AHCOHS301A - Contribute to OHS Processes

Caption: Emergency Producers

Page 56 of 60

AHCOHS301A - Contribute to OHS Processes

OHS consultation and communication

Written Content

OHS consultation and communication benefits everyone at the place of work, and results in:

• awareness of the need for OHS in the workplace

• Employees having the knowledge and skills to meet their ‘Duty of Care’

• better OHS decisions

• better workplace health and safety standards

• better working relationships

• Increased morale and job satisfaction.

OHS consultation is any informal or formal activity that seeks the views of those at the workplace before OHS decisions are made

Images

Caption: Duty of Care

Page 57 of 60

Designated personnel

Written Content

Designated personnel includes:

supervisors

managers

team leaders

management

OHS personnel other persons authorised or nominated by the enterprise or industry to:

perform specified work

approve specified work

inspect specified work

Direct specified work.

AHCOHS301A - Contribute to OHS Processes

Page 58 of 60

AHCOHS301A - Contribute to OHS Processes

Images

Caption: Occupational safety and Health issues resolution process

Page 59 of 60

Assessment

Question

Answer

Assessment

Question

Question No 1 English

There are a number of ways you can contribute to a safer workplace

1.

understanding how OHS consultation and communication should be managed in the workplace

2.

improving your communication skills

3.

making sure that you understand the safety rules in your workplace

1,2,3

AHCOHS301A - Contribute to OHS Processes

Question No 1 other persons authorised or nominated by the enterprise can be

1.

perform specified work

2.

approve specified work

1,2,3

3.

inspect specified work

4.

as they please

English

Answer

Page 60 of 60