2.1 Synthesis of sol-gel CNPrTEOS

1 1 Experimental

2 1.1

Synthesis and Optimization of sol-gel CNPrTEOS

3 The sol-gel CNPrTEOS nanomaterial was initially prepared by mixing 1 mmol of

4 CNPrTEOS, 3 mmol of water, 2 mmol of NH

4

OH at pH 12 and 5 mmol of methanol as solvent

5

6

7

8 in a beaker. The mixture was stirred by using a magnetic stirrer for about 15 min and then left at room temperature (25ºC) for one day until gel was formed. The gel was then washed with 3×10 mL of methanol, followed by 3×10 mL of deionized water. The washed powder was dried at

100ºC for one day till completely dried and finally ground using pestle and mortar. The product

9 was placed in a bottled sample bottle. A number of parameters influencing the synthesized

10 sorbent such as precursor concentration, type of solvent, base catalyst pH and water amount were

11 investigated in the sol-gel process.

12

13 2 Results and discussion

14 2.1 Synthesis of sol-gel CNPrTEOS

15 The sol-gel sorbent was prepared by using four main materials, namely CNPrTEOS as a

16 sol-gel precursor, ammonium hydroxide as a base catalyst, water as a hydrolysis agent and the

17 solvent to obtain a homogeneous reaction mixture. The sol-gel process corresponds to the

18 generation of colloidal suspensions (sol) which are later converted to viscous gel and the solid

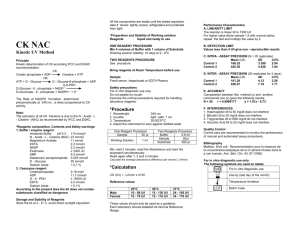

19 material. The synthesis of sol-gel CNPrTEOS undergoes two steps of reactions. The first step is

20 hydrolysis of the precursor. Hydrolysis is completed with the help of alkaline catalyst (Figure

21 1A). In the hydrolysis step reactive silanol group and ethanol are produced. The second step is

22 polycondensation of the hydrolyzed products to yield siloxane oligomers and form silica network

23 of siloxane bonds. In the polycondensation step, the hydrolyzed product produces a three-

24 dimensional silica network with the elimination of water. Figure 1B and 1C show water and

25 alcohol condensation of CNPrTEOS, respectively.

26

27

28

29

Figure 1. Hydrolysis of precursor CNPrTEOS catalyzed by base (NH

4

OH)

30 In this work, sol-gel chemistry was used to chemically bind highly polar cyanopropyl (-

31 CN) moieties to an evolving sol-gel network structure. The sol-gel material as sorbent in SPE

32 provided an efficient simultaneous extraction of OPPs from aqueous solution. The CNPrTEOS

33 was chosen due to its potential affinity toward polar compounds (in our case dicrotophos),

34 because the CNPrTEOS have polar cyano functional groups that is able to attract polar

35 analytes[1]. In the sol-gel process, a gel can be formed via hydrolytic poly-condensation of a sol-

36

gel precursor followed by aging and drying [2, 3].

37

38 2.2 Optimization of sol–gel process parameters

39 In order to obtain a more porous sorbent material with high surface area, the effect of a

40 number of the synthesis parameters were investigated in the sol-gel process. These effects were

41

also optimized using the classical one variable at time methodology [4].

42

43 2.2.1Precursor concentration

44 In sol-gel method, the success of the hydrolysis and condensation processes depends on

45 the quantitative ratio of alkoxy groups in the initial system with respect to solvent and

46

concentration of other ingredients [5]. The effect of varying precursor concentration (0.5, 1, 2, 3

47 mmol) in the sol-gel CNPrTEOS produced was studied. Other sol-gel synthetic parameters were

48 kept constant as follows: 3 mmol water, 5 mmol MeOH, 2 mmol NH

4

OH at pH 12 and drying

49 temperature at 100ºC. The SPE was performed using four different amount of sol-gel

50 CNPrTEOS to compare the extraction efficiency of each sorbent to find the optimum sorbent

51 amount which was then used in method validation. Addition of more CNPrTEOS to the starting

52 mixture of reaction led to a lengthened siloxane network resulting in a delay in the gelation time

53

[6]. On the other hands, more CNPrTEOS resulted in an increase in the percentage of carbon,

54

hydrogen and nitrogen and caused the nature of the sorbent to be more hydrophobic [7]. The

55 hydrophobic nature reduced the ability of CNPrTEOS sorbent to extract the polar OPPs

56 dicrotophos. Therefore, sol-gel CNPrTEOS with 1 mmol of precursor was selected as the best

57 sorbent as it provides the highest extraction efficiency and shortest gelation time. The effect of

58 different concentration of CNPrTEOS on extraction efficiency of OPPS is shown in Figure 2.

59

60 Figure 2. Effect of different precursor concentration of the produced sol-gel CNPrTEOS on

61

62 the extraction efficiencies of the three selected OPPs. Sol-gel synthesis condition: 3 mmol water,

5 mmol MeOH, 2 mmol NH

4

OH at pH 12 and drying temperature at 100ºC. Extraction

63

64 conditions: 2 mL methanol of as eluting solvent at flow rate of 0.5 mL min

-1

and 10 mL sample volume (0.1 µg mL -1 ).

65

66 2.2.2 Solvent type

67 Another sol-gel synthesis parameter studied was the type of solvent. Four solvents were

68 chosen, namely methanol (MeOH), ethanol (EtOH), npropanol (PrOH) and nbutanol (BuOH).

69 Methanol showed high extraction efficiency based on highest peak area (figure not shown).

70 Other sol-gel synthetic parameters were kept constant as follow: 1 mmol CNPrTEOS, 2 mmol

71 NH

4

OH at pH 12 and drying temperature at 100ºC. As molecules assemble together (polymerize)

72 into sol, the solvent used should be able to keep the sol-gel materials dissolved so that they do

73 not precipitate out of the liquid. Also, the solvent can play a role in helping the sol-gel materials

74

mix together to ensure a homogenous gel network can be formed [8].

75

76 2.2.3Effect of pH of base catalyst

77 The alkaline (basic) catalysts, ammonium hydroxide was used, to enable fast hydrolysis

78 of all of the silanol groups of the precursor, which lead to an easy formation of uniform network

79 particles in the sol and increase the size of the pore volume [9, 10]. The base catalyst pH

80 parameter optimized was pH values 9, 10, 11 and 12. Other sol-gel synthesis parameters were

81

82 kept constant as follow: 1 mmol CNPrTEOS, 3 mmol water, 5 mmol MeOH, and drying temperature at 100ºC. Figure 3 shows the extraction efficiency of the sol-gel CNPrTEOS

83 synthesized using different basic pH value. The basic pH value of 10 was chosen for further

84 analysis as it showed the highest extraction efficiency of the OPPs (based on peak area from

85 HPLC-UV).

86

87 Figure 3. Variation of extraction efficiency with basic pH of catalyst values for three

88 selected OPPs using sol-gel CNPrTEOS as SPE sorbent. Sol-gel synthesis condition: 1 mmol

89 CNPrTEOS, 3 mmol water, 5 mmol MeOH and drying temperature at 100 ºC. Extraction

90

91 conditions: 2 mL methanol of as eluting solvent at flow rate of 0.5 mL min

-1 and 10 mL sample volume (0.1 µg mL -1

).

92

93 2.2.4 Effect of H

2

O amount

94 Hydrolysis of alkoxides can produce different materials according to different parameters

95 and base or acid catalysis reaction. Hydrolysis of silicon alkoxides is crucial in sol-gel synthesis.

96 The proportion between the Si: H

2

O ratio is a critical point which should be noted during the sol-

97 gel preparation. The molar ratio of H

2

O: Si(OR)

4

in the sol should be at least 2:1 to approach

98 complete hydrolysis of the alkoxides. The water quantity should be 2-5-time in the

99 stoichiometric proportion with a silicon alkoxides concentration with 5-10% of alcohol in order

100 to obtain high porosity sol-gel [11]. Therefore study on the effect of amount of water is

101 important to ensure enough water was used in the process. For optimization of water amount,

102 four different amount of water was selected, that are 1 mmol, 2 mmol, 3 mmol, 4 mmol, 5 mmol,

103 6 mmol and 7 mmol. According to extraction, peak area of the OPPs enhanced slowly and

104 reached a maximum after using 5 mmol amount of water for the synthesis of sol-gel CNPrTEOS

105 SPE. Moner-Girona et.al [6] investigated the effect of water: TMOS ratio on the size of silica

106 aerogel microparticles and found that higher ratios give smaller particles. Larger surface area for

107 extraction provides higher extraction efficiency. However, as the water amount was increased to

108 7 mmol, the chemical reactions were enhanced and the gelation time reduced. The hydrolysis and

109 condensation process may be retarded, thus declined the extraction efficiency of the OPPs.

110 Further increase in volume of water will enhance the pore sizes thus causing a reduction in the

111 surface area of sol-gel materials [12]. This explains the reduction of peak area (figure not shown)

112 of OPPs when 7 mmol of water was used. Therefore, 5 mmol of water was chosen as the

113 optimum to synthesis the sol-gel CNPrTEOS prior to extraction of OPPs using SPE. The

114

115 optimum sol-gel synthesis parameters are 1 mmol CNPrTEOS, 5 mmol MeOH, 5 mmol water, ammonia as base catalyst pH 10, room temperature (25

C) and heat drying of product at 100

C

116 for one day.

117

118

119

120

121 References

122 [1] Wan Ibrahim, W. A., Abdul Keyon, A., Prastomo, N., Matsuda, A., J. Sol-Gel. Sci. Technol.

123 2011, 59, 128-134.

124 [2] Bagheri, H.,Piri-Moghadam, H.,J. Chromatographia. 2014,77, 1185-1194.

125 [3] Kulkarni, S., Fang, L., Alhooshani, K., Malik, A., J. Chromatogr. A 2006, 1124, 205-216.

126 [4] Khan, B.A.,Farid, A.,Asi, M.R.,Shah, H.,Badshah, A.K., J. Food Chem. 2009,114, 286-288.

127 [5] Dimitriev, Y.,Ivanova, Y.,Iordanova, R., J. Univ.Chem. Tech. Metall. 2008,43,181-192.

128 [6] Moner-Girona, M. ,Roig, A.,Molins, E.,Llibre, J., J. Sol-Gel Sci. Techn. 2003,26, 645-649.

129 [7] Wan Ibrahim, W. A., Wan Ismail, W.N., Abdul Keyon, A., Sanagi, M.M., J. Sol-Gel Sci.

130 Techn. 2011, 58, 602-611.

131 [8] Kabir, A.,Furton, K.G.,Malik, A.,J.TrAC Trend. Anal. Chem. 2013,45, 197-218.

132 [9] Abid, H.R.,Ang, H.M., Wang, S.,J. Nanoscale. 2012,4, 3089-3094.

133 [10] Wagh, P., Ingale, S., J. Ceram. Int. 2002, 28, 43-50.

134 [11] Milea, C.A., Bogatu,C., Duţă, A.,Bull Transilvania Univ Braşov Series I: Eng Sci. 2011, 4,

135 60-66.

136 [12] Lopez, T.,Ortiz, E., Alexander ‐ Katz, R.,Quintana, J.A. P.,Gonzalez, R.D.,Lottici,

137

138

P.P.,Marino, I.G., J. Bio. Mater. Res. B. 2010, 93, 401-406.