Nanotechnology: Materials, Sol-Gel & Applications

advertisement

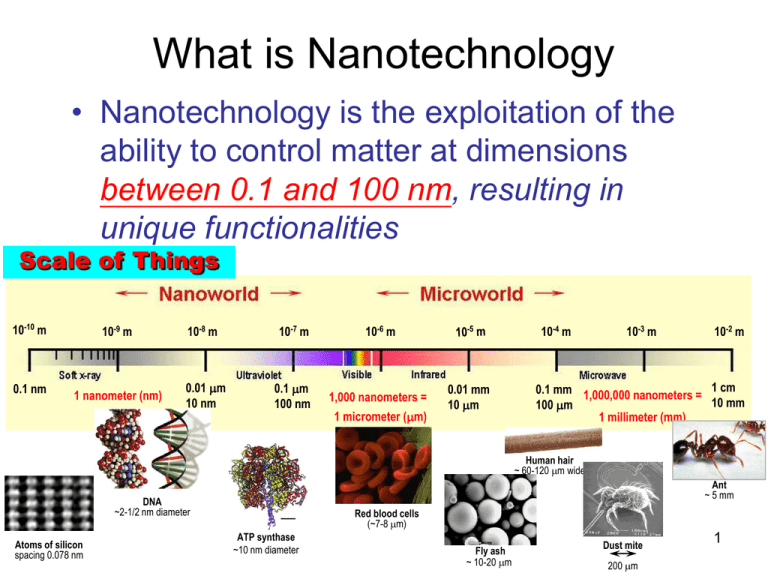

What is Nanotechnology • Nanotechnology is the exploitation of the ability to control matter at dimensions between 0.1 and 100 nm, resulting in unique functionalities Scale of Things 10-10 m 0.1 nm 10-9 m 10-8 m 10-7 m 1 nanometer (nm) 0.01 mm 10 nm 0.1 mm 100 nm 10-6 m 1,000 nanometers = 1 micrometer (mm) 10-4 m 0.01 mm 10 mm 10-3 m 10-2 m 0.1 mm 1,000,000 nanometers = 1 cm 10 mm 100 mm 1 millimeter (mm) Human hair ~ 60-120 mm wide Ant ~ 5 mm DNA ~2-1/2 nm diameter Atoms of silicon spacing 0.078 nm Red blood cells (~7-8 mm) ATP synthase ~10 nm diameter Fly ash ~ 10-20 mm Dust mite 200 mm 1 Organic-Inorganic Nanocomposite Materials Properties of Organic & Inorganic Material Two Influencing Factors 1.The interface between the organic & inorganic phase 2.Domain sizes of these two phases 2 Sol-Gel Technology The main idea of the sol-gel process is the spontaneous formation of a dual phase material (gel), prepared from the solution (sol), containing inorganic precursors ( 前 驅 物 ) and stabilizing agents with hydrolysis(水解) & condensation(縮合) reaction. Further transformation of the gel phase is driven by the evaporation of the solvent, and the subsequent formation of the xerogel phase.(熟化aging). Drying of the xerogel completely removes solvent molecules, leading to further aggregation of inorganic clusters and the formation of solid materials. Hydrolysis Reaction Condensation Reaction 3 Sol-Gel Technology (cont’d) • Control Parameters – Precursors – Concentration of Metal Salts – Temperature – Catalysts – pH Hydrolysis & Condensation • Advantages – Low temperature route (below 200oC) – Uniform particle size distribution – Provides good homogeneity – Concentration of metals in the coatings can be controlled with ease – Chemical purity of nanocomposites • Drawbacks – high cost for the majority of alkoxide precursors – long processing times 4 Applications Anti-Abrasion Anti-Rusting Hydrophobic Anti-Glare 5 Nano Hybrid Material • PEACCO NON-CHROMATE PLASTICAL/ METAL SURFACE TREATMENT SOLUTIONS – Nanocomposites • The hybrid from inorganic nanodispersion metal and organic epoxy . – Sol-Gel Method • uses an aqueous solution to apply on the metal to form a organic-inorganic hybrid thin film. – Traditional Coating Method • This coating can be applied on the metal by many techniques like dip, spin, spray, or roller coatings. – Strong chemical bonding • This organic-inorganic hybrid coating can chemically bond to the metal and can also chemically bond to organic adhesives/paints. – Apply on Various Metals and Plastics • By modifying the composition of the coating solution, this technology can apply on different kinds of metals and plastics. Strong chemical bonding 6