ALCOA Sustainable Campus

advertisement

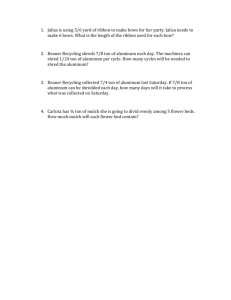

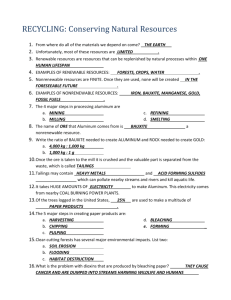

ALCOA Sustainable Campus Fall 2013 – EDSGN-100 Section 003 Team #4: Ryan Butler, Rin Choi, Puvanan Selvam, Cameron Gray Introduction Aluminum is one of the most widely used and available metals in society. However, not many people know that among the consumer products containing aluminum, most of them can be recycled. Chip bags are made out of aluminum foil laminated with plastic. This causes confusion when recycling because people do not realize that it contains aluminum foil. Therefore, most snack bags are thrown into the trash which makes it impossible to recycle. Our group has come up with an idea to easily recycle both the plastic and aluminum foil. This proposal is made feasible by creating a method to separate the recyclable materials. Our idea is to incorporate a plastic tab in a chip bag which makes it possible to pull away the plastic laminate. 1 Contents: Introduction A. Understanding the Needs, Requirements and Definition of the Problem B. Detailed Description of Competing Alternative Conceptual Options C. Concept Options Analysis D. Final Concept Proposal Division of Labor: Ryan Butler: Wrote each chapter of report, Edited each chapter and website, Made presentations, Contributed idea concepts Rin Choi: Web Master, Designed concept model in solid works, Designed Block Flow and Process Flow diagrams Cameron Gray: Wrote each chapter of report, Edited each chapter, Contributed idea concepts Puvanan Selvam: Edited each chapter, Contributed conceptual ideas 2 Ryan Butler, Rin Choi, Cameron Gray, Puvanan Selvam EDSGN 100 Section 003 ALCOA Sustainable Campus A. Understanding the Needs, Requirements and Definition of the Problem The top ten aluminum manufacturers produce approximately 20 million tonnes annually. The leading manufacturers being UC RUSAL, Alcoa, and Alcan. The raw materials come mostly from South East Asia, West & Central Africa, and parts of South America. Some of the largest aluminum processing plants are located in Hongjun, China (1060000 t/year); Jebel Ali, UAE (1040000); and Krasnoyarsk, Russia (1010000). Some aluminum products include auto parts, license plates, siding for houses, window frames, power lines, beverage cans. Aluminum is widely used in the packaging of consumer products, such as food. This packaging is widespread on Pennsylvania State University Park campus by the plethora of vending machines in each residence hall, student activity buildings, and academic buildings. Aluminum packaging is also present in all of the dining halls on campus. Also, packaging for snacks, such as potato chips, is made out of aluminum. The major problem with aluminum in packaging is that it is laminated with plastic or other materials that aren’t made out of metal. Because of this, one cannot recycle it properly. People end up recycling the packaging incorrectly or they just throw it in the trash. The first stage of the aluminum packaging life cycle is assembling the raw materials into 3 the product. In this case, aluminum and plastic laminate are the materials. After assembling the packaging, it is packaged with consumer products, such as food. After this step, the packages with food are transported to campus via shipping trucks. Then, people consume the products and attempt to recycle the packaging. The packaging is then either mixed with other trash or recyclable materials. The aluminum laminated with plastic is impossible to recycle without separating the materials. We are investigating a new, sustainable aluminum packaging product that can be recycled. - Areas where raw aluminum is located 4 Works Cited “What is aluminum used for? – Curiosity.” Curiosity. N.p., n.d. Web. 30 Oct. 2013. <http://curiosity.discovery.com/question/what-is-aluminum-used-for>. “Aluminum Industry.” All about aluminum. N.p., n.d. Web. 30 Oct. 2013. <http://www.aluminiumleader.com/en/serious/industry/>. B. Detailed Description of Competing Alternative Conceptual Options Initial Ideas Rin Choi: - Aluminum body for a CATA bus: o Human factors: Does not have much of an effect due to human factors because once the body is replaced, no one would notice the difference. O Innovative: It is innovative because it makes the bus lighter, therefore using less fuel. O Quality of life: Because the bus is using less fuel, it provides better quality of life, less pollution. O Implementation: It is very hard to implement this on campus, because it would be very costly to replace buses. O Economic viability: Annual cost of maintaining the bus would be much more inexpensive than regular buses with heavy frames. Ryan Butler: - Chip bag: o Human factors: People may be lazy to go through the process of separating aluminum from the plastic laminate. O Innovative: It solves the problem with recycling chip bags incorrectly. O Quality of life: Because we are recycling aluminum from chip bags, we can 5 reduce a significant amount of landfill and waste. O Implementation: The process of adding a plastic tab to separate the components would be fairly simple. O Economic viability: This process increases the amount of aluminum recycling, therefore reducing the amount of aluminum to be produced. (Aluminum is very expensive to produce.) Cameron Gray: - Foamed aluminum dorm insulation: o Human factors: There is no individual effort required from the consumers, because once it is installed, there is no further maintenance o Innovative: It is innovative because it is sound proof, fire resistant, light weighted, and relatively inexpensive. O Quality of life: It would keep the buildings quieter and well insulated. O Implementation: It would be very hard and time consuming to replace the walls with foamed aluminum insulation, because it would require tearing down the walls. O Economic viability: It would not be expensive to produce the foamed aluminum, but it would be very expensive to implement and install. Puvanan Selvam: - Aluminum takeout box: o Human factors: The only effort needed from the consumers is to return the box, which is not likely to happen. (Laziness is big factor.) o Innovative: It is innovative because it keeps the food warm and the takeout box does not melt due to the food’s temperature. O Quality of life: Because the takeout box would not melt due to the food’s temperature, the harmful emissions would not be consumed. Also, this reduces landfill and waste, because the takeout boxes are not to be thrown away. 6 O Implementation: It would be hard to implement because the corporation is already set to supply the Styrofoam boxes, therefore it would require negotiations. O Economic viability: It reduces landfill and waste. C. Develop and Compare Initial Concepts *Block Flow and Process Flow Diagrams on next page* 7 Block Flow Diagram 8 Process Flow Diagram 9 D. Final Concept Selection and Description Aluminum is one of the most widely used and available metals in society. However, not many people know that among the consumer products containing aluminum, most of them can be recycled. Chip bags are made out of aluminum foil laminated with plastic. This causes confusion when recycling because people do not realize that it contains aluminum foil. Therefore, most snack bags are thrown into the trash which makes it impossible to recycle. Our group has come up with an idea to easily recycle both the plastic and aluminum foil. This proposal is made feasible by creating a method to separate the recyclable materials. Our idea is to incorporate a plastic tab in a chip bag which makes it possible to pull away the plastic laminate. Other considered ideas included foamed aluminum for dorm insulation, aluminum body for a CATA bus, and an aluminum takeout box. During the selection process (which can be viewed below), our best ideas were the aluminum takeout box and a recyclable chip bag. We concluded that the recyclable chip bag was the best option based on five categories: human factors, innovation, quality of life, implementation, and economic viability. It scored a 2 for human factors because it requires individual effort. It scored a 4 for innovation because it has not been done before. It scored a 3 in quality of life because it could significantly reduce land fill waste and increase the quality of the environment. It scored a 4 on implementation because chip bags are available everywhere and it is a part of a fast consumer cycle. It scored a 5 in economic viability because it requires a sole implementation of a plastic tab. 10 Fig. 1. Solidworks Screen Shot of Chip Bag with Tab Concept Plastic Pull-away Aluminum Pull-away 11 Fig. 2. Solidworks Zoomed Screen Shot of Chip Bag with Tab Concept Plastic Pull-away Aluminum Pull-away 12