project 02 - Personal.psu.edu

advertisement

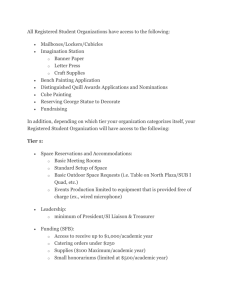

The Efficiency of Locomotive Catalytic Converters Matt McCarthy, Derek Von Nieda, Muhammad Nazmi Mohd Faisul, Salim Bin Ghouth Pennsylvania State University Introduction to Engineering Design Class December 3, 2015 1 Abstract There is a city, Pittsdelphia, where approximately 165,000-tons of freight or minerals (coal, etc.) per day travel in or out of the port city via rail. NOx emitting from locomotive engines is causing smog, which is a complaint of the city residents. The locomotives must meet the EPA requirements at Tier 3 or Tier 4 by reducing the NOx emission at least 70% less. However, the changes associated with meeting the EPA requirements are supposed to be costly effective. Thus, we chose to upgrade the locomotives by adding a catalytic converter that can reduce the NOx emissions in order to reduce the smog, as well as meet the EPA requirements with less expense. We concluded in our research that the product satisfies all the involved parties (the stakeholders). Regarding to both the railroads and GE, it is financially affordable. On the other hand, it reduces the NOx emissions to satisfy the EPA requirements and the Pittsdelphia residents since they will not have the smog over their city any more. Additionally, the freight is delivered on time. 2 Table of Contents Abstract 2 List of Figures and Tables 4 Summary 5 Introduction 6 Methods, Assumptions, and Procedures 9 Results and Discussion 16 Conclusions 17 References 18 Appendixes 18 3 List of Figures Figure 1. Schedule page #11 List of Tables Table 1. Design metrics matrix to understand the customer needs page #12 Table 2. Calculation results page #13-14 Table 3. Concept scoring matrix page #15 4 Summary Problem Locomotives carrying 165,000-tons of freight or minerals pass through the city of Pittsdelphia every day. The engines of the locomotives emit NOx gas that creates smog over the city. The residents of Pittsdelphia are complaining about the amount of smog generated by the locomotives. Pittsdelphia must continue to meet EPA requirements, but is looking for a way to reduce smog while retaining the freight capacity. There are some suggestions to provide a cost effective solution that reduces the smog, meets the EPA requirements, and for the freight to be delivered on time. Sell existing fleet and purchase new locomotives, upgrade fleet with exhaust after-treatment hardware, or utilize alternate fuels (Biodiesel, CNG, LNG, etc.), which may produce less NOx, are efficient solutions. Otherwise, shipping the freight alternatively by either air, sea, or ground-trucking may be a good solution. Proposed Solution We believe that we should upgrade the locomotives by including a catalytic converter. A catalytic converter is a device that uses a catalyst to convert harmful gases such as nitrogen oxides into harmless compounds. It acts as a filter by eliminating the emissions from the engine and filtering out the clean air. The catalytic converter will reduce the NOx emissions and will also be cost effective for railroad companies in the short run (Whitehorn). 5 Conclusion Catalytic converters have proven to be the best solution to the problem. They are able to filter out the harmful gases and remove the smog that is above the city of Pittsdelphia. It will also be much more feasible for railroads to switch to a catalytic converter rather than completely change the tier of the locomotives while saving a substantial amount of money. The locomotive catalytic converter will satisfy all stakeholders especially those that will pay for the product. Introduction Stakeholders: 1. EPA: Existing Conditions: Preferred Conditions: ● Tier 2 locomotives ● Wants the minimum are no longer meet requirements to be the minimum EPA met. Will penalize requirements and those who don’t meet must be upgraded requirements. to tier 3-4. ● Wants as few emissions as possible. 6 2. Pittsdelphia: ● Pittsdelphia ● Want the smog to be residents are reduced. unhappy with the smog caused by locomotives. 3. Railroad: ● Don’t want to disrupt the local economy. ● Tier 2 locomotives ● Wants to meet the are no longer meet minimum the minimum EPA requirements so it is requirements and not fined and can must be upgraded continue operations. to tier 3-4. ● Wants to spend as ● Approximately little money as 165,000-tons of possible on freight or minerals improvements. are transported through city. Tier 2 locomotives ● Wants viable solution product is being are no longer meet (must meet tier 3 built for GE: minimum EPA requirements) that requirements and could be implemented must be upgraded elsewhere. 4. GE - This ● to tier 3-4. 7 ● Engines are ● Must be cost effective emitting NOx. for GE and customers. Stakeholders: ● EPA: ❏ US Environmental Protection Agency. ● Pittsdelphia: ❏ The city where the railroad is, and the fright or minerals are transported through. ● Railroad: ❏ The operating company of the locomotives, which transports the fright or minerals. ● GE - This product is being built for GE: ❏ The company whose job is to upgrade the locomotives, and the product is being built for it. Existing Situation: ● Tier 2 locomotives are no longer meet minimum EPA requirements and must be upgraded to tier 3-4. ● Pittsdelphia residents are unhappy with smog caused by locomotives. ● Engines are emitting NOx. ● Approximately 165,000-tons of freight or minerals are transported through city. All the problems associated with the current locomotives are basically depending on the increasing emissions of the NOx. The NOx emissions are no longer satisfying the EPA requirements, which must be tier 3 or 4. They are the main cause of the smog over the city of Pittsdelphia, about which the city residents are complained. The railroad and GE are both sharing the concerns of the cost of the 8 final product while the EPA is pretty much unconcerned. Pittsdelphia is in more of a middle ground because while they are not directly affected by the cost of the solution, the health of the railroad has a large bearing on the city’s economy. Approximately 165,000-ton of the fright or minerals are transported through the city, and the residents are concerning about the city’s economy. Without the railroad, the city wouldn’t be able to transport all of the goods arriving in its port. Since the railroad and city have combined interests, it is possible that there could be active cooperation between the two stakeholders. Preferred Conditions: ● EPA: ❏ Wants the minimum requirements to be met. Will penalize those who don’t meet the requirements. ❏ Wants as few emissions as possible. ● Pittsdelphia: ❏ Wants the smog to be reduced. ❏ Doesn’t want to disrupt their local economy. ● Railroad: ❏ Wants to meet the minimum requirements so it is not fined and can continue operations. ❏ Wants to spend as little money as possible on the improvements. ● GE: ❏ Wants a viable solution (must meet tier 3 requirements) that could be implemented elsewhere. ❏ Must be cost effective for GE and customers. Although all involved parties have different motivations for reducing NOx emissions to meet at least tier 3 requirements, They each share an interest in doing so. The EPA wants as less emission as possible. In other words, it wants the emissions to meet the tier 3 or 4. The Pittsdelphia residents want the smog to be reduced and their economy to be stable. Railroad and GE are interested in locomotives that meet the minimum requirement and costly effective, so the railroad can still be operating. 9 Consequently, in our project we are focusing on: How can we reduce the emissions with a financially affordable product that satisfies all stakeholders? Methods, Assumptions, and Procedures Methods General electric has asked our group to determine a way to reduce emissions from locomotives at an affordable cost. We are told to consider the emissions requirements, cost, time of delivery, freight capacity and public opinion. We began by brainstorming different solutions to the problem. We continued to brainstorm and came up with catalytic converters, solar panels, hybrid train, and electric trolleys as our possible solutions. However, we felt that researching four different solutions would prove to be extremely challenging in the limited amount of time we were given. We decided to eliminate two out of the four topics, the hybrid train and the electric trolley. Hybrid technology is still being researched today and does not offer many resources and the electric trolley also does not contain much information and could prove to be expensive for railroad companies. We had then decided that it would be more efficient for the group if we all focused on one topic. We determined that catalytic converters would be our main point of research. Catalytic converters are frequently used today while solar panels contain a limited amount of information and are not applied to locomotives as often. Our group then created a schedule (Figure 1) that would layout our objectives and time frame. This proved to be extremely beneficial since it would clearly and effectively map out what we have discussed and what we still needed to discuss. Each member researched their information with the use of both Google and the sources provided by the Penn State Engineering Library. Certain questions we sought to answer in each of these resources 10 consisted of how catalytic converters are used today, how do they work, how much it costs, and how will it reduce emissions. Each member put placed their information into a single document so all of our information could easily be located. It was especially beneficial when it was time to answer our question. Figure 1 11 Customer Needs Target specifications were formulated in order to understand what was necessary for customer satisfaction. Specifics varied from environmental friendly to producing a cost effective product. This specifications were found in the customer’s report and briefings as well as the engineering team’s intuitive senses. Parameters chosen here helped to give direction and focus to the multitude of possible designs for the problem. A list of customer needs and their related metrics are shown below in the Table 2. Design Metrics Needs Filters out harmful particles Eco Friendly X Cost Effective Fuel Efficient Reducing maintenance cost Less volume per distance Tier 3 or higher Less smog production Goods delivered at the expected time X X Meets EPA req. X NOx emission X Timely Delivery X Table 1: Design metrics matrix to understand the customer needs. 12 Assumptions The assumption most integral to our argument is our presumption that the Rail Network is seeking the least expensive option that can satisfy their criteria. We made this assumption on the premise that businesses generally look for the most cost effective option to allow them to continue to be viable and produce the most profits. While some groups may have weighed environmental concerns more heavily, we elected to address them at the necessary level, but focus on what would make the most viable option for the business at the heart of this analysis. We also had an initial assumption that a catalytic converter would be the cheapest option of those presented by GE and those which we were able to come up with. This assumption was informed by our experience with automobiles and the lack of use of alternative fuel sources. We followed this presumption up with research and based on our analysis metrics we concluded that it was the best option. Calculations for the project was made so that the locomotive could function properly and stay within the recommended EPA requirement. Some of the factors that needed to be computed were: ❖ How much does the fuel cost per trip? ❖ How much does the return trip cost in fuel? ❖ How much NOx? ❖ How much particulates? ❖ How much NOx and particulates could we save if we moved to Tier 4? At the end of this section Table 3 presents the results of these calculations. We were using unit skills of physics to calculate the result. For an in depth look at the calculations, see Appendix A. Fuel cost per trip $ 0.98 / trip 13 Amount of fuel used per trip 1.06 gallon / trip Amount of NOx emitted per trip 55 g / trip Amount of particulates produced per trip 2 g / trip Amount of NOx emitted per trip (Tier 4) 13 g / trip Amount of particulates produced per trip (Tier 4) 0.3 g / trip Change in amount of NOx if moved to Tier 4 42 g / trip Change in amount of particulates if we moved to Tier 4 1.7 g / trip Table 2: Result of calculation. Procedures Concept Generation Instead of simply developing a single iterative design, more time was invested in concept generation in order to produce more confidence in the final results. Based on the research and target specifications, some concepts were initially produced in the brainstorming session. Inspirations for many of these concepts included individual creativity, existing models and patent ideas. Some ideas overlapped and others are seem underdeveloped, so certain concepts were combined. After this initial analysis, five concepts remained and thus become eligible for a stricter screening method. Concept Selection A concept scoring matrix was made to narrow down the ideas from concept generation. It was determined that the cost effective, complexity and practicality should be the baseline for 14 comparison because of a couple factors. Liquefied Natural Gas (LNG) would cause difficulties and large expenses in converting current diesel fuel oriented infrastructure to LNG infrastructure. China Electric Trolley couldn’t be chosen either because this system is very new and doesn’t have a long story behind it, which causes hesitation. With these factors considered, the concept screening matrix was made and can be found below in Table 3. Metrics Concepts Hybrid train Solar Panels China Electric Trolley Catalytic Converter LNG Powered Train Eco Friendly + + + + + Cost Effective - - - + - Fuel Efficient + 0 0 0 0 Meets EPA req. + + + + - NOx emission + + + + + Timely Delivery 0 0 0 0 - Total 3 2 2 4 -1 Table 3: Concept scoring matrix to narrow down the ideas from concept generation. With the scoring matrix completed, scores were totaled and catalytic converter was chosen as the final result. 15 Results and Discussion Having researched a number of methods to satisfy stakeholders and reconcile their preferred conditions, the following information became evident. In regards to the initial investment needed to implement the proposed solutions, the catalytic converter was by far the cheapest option, only requiring a retrofit of current engines. By contrast, the hybrid and especially the liquid natural gas options have significantly larger base costs and require the purchase of new engines. Meanwhile, the China electric trolley and solar powered train options were deemed infeasible because of a lack of available data and an inability to effectively implement them. Although the initial modest cost of a catalytic converter makes it an attractive option, the fuel savings provided by hybrid and liquid natural gas powered trains has the potential to make up for their more expensive implementation costs and produce a net savings for railroads. However, this return on investment, particularly in the case of liquid natural gas, would not take effect for years and would be further hampered by current economic conditions. At the moment, fuel prices for locomotives are exceptionally low, making fuel saving measures less attractive to railroads. The argument for liquid natural gas is further undermined by the costs of the infrastructure that would be needed to effect its use. With these lackluster savings and higher initial costs, it is likely that railroads would end up leaning towards the less exciting but more economical catalytic converters. Finally, in regards to reducing emissions, catalytic converters, hybrid engines, and liquid natural gas all succeed in meeting the EPA’s tier 3 requirements. Although there is an argument that hybrid and liquid natural gas trains could offer a better deal over the course of years or decades, an objective analysis suggests that catalytic converters will be viewed as the best way forward by railroads. 16 Conclusion After doing lengthy research on catalytic converters and other alternative methods of reducing emissions, we have come to the conclusion that a catalytic converter is the best available solution to the existing problem. It will allow the Railroad to meet the requirements set forth by the EPA and the City of Pittsdelphia, while having the smallest possible financial impact on the company. Meanwhile, with this solution providing an attractive option for other railroads across the nation, GE would stand to benefit from the adding catalytic converters to its pallet of options. Taking everything into consideration, this solution satisfies all involved stakeholders, while focusing on creating the best possible situation for the stakeholder who will purchasing and utilizing the product. By our assessment, this makes it the most likely option to be adopted as the solution for the railroad. 17 References ● Source 1: Whitehorn, James. "Locomotive Catalytic Converter Manufacturing."Catalytic Converter Manufacturer Synergy Catalyst. N.p., 15 June 2012. Web. 03 Dec. 2015. ● "LNG Could Push Diesel Trains Into History Books - GE Reports." GE Reports LNG Could Push Diesel Trains Into History Books Comments. N.p., 16 Apr. 2014. Web. 7 Nov. 2015. <http://www.gereports.com/post/93343698908/lng-could-push-diesel-trains-into-history-books/> ● Guss, C. (2014, 12). No more tiers. Trains, 74, 16. Retrieved from http://search.proquest.com/docview/1622248157?accountid=13158 ● Hayes, R. E., A. Fadic, J. Mmbaga, and A. Najafi. "Modelling of the Automotive Catalytic Converter." Catalysis Today, n.d. Web. Appendixes Appendix A: Physics Calculation Distance per gallon of diesel (given) 470 miles / gallon Distance per trip into the city (assumed) 500 miles / trip Cost of diesel fuel (given) $ 2.50 / gallon Amount of NOx emitted in Tier 2 (given) 5.5 g / hp-hr Amount of particulates produced in Tier 2 (given) 2 g / hp-hr Amount of NOx emitted in Tier 4 (given) 1.3 g / hp-hr Amount of particulates produced in Tier 4 (given) 0.03 g / hp-hr Average speed of locomotive (assumed) 50 miles / hour Data was collected from the GE presentation 18 Fuel cost per trip Amount of fuel per trip Amount of NOx emitted per trip (Tier 2) Amount of particulate produced per trip (Tier 2) Amount of NOx emitted per trip (Tier 4) Amount of particulate produced per trip (Tier 4) Change in amount of NOx emitted per trip (Tier 4) Change in amount of particulate produced per trip (Tier 4) 19