here - The Automotive Industrial Partnership

advertisement

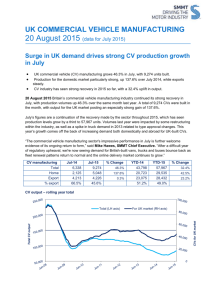

12 October 2015 Problem solving saves millions for automotive industry A major training innovation bringing together the supply chain with the UK’s motor manufacturing giants has saved the automotive sector millions of pounds with the potential to save millions more. The Advanced Problem Solving training programme is being delivered and funded by the Automotive Industrial Partnership launched earlier this year, bringing together industry and government to ensure the UK’s automotive sector has the pipeline of skills talent it needs now and for the future. The Advanced Problem Solving Programme is led by Toyota Motor Manufacturing (UK) Ltd on behalf of the wider industry. “The programme began as a Toyota initiative, then it was expanded to include our local supply chain and now it is being rolled out across the UK,” said Andrew Parsons, Section Manager, Technical Skills Development, Toyota Manufacturing (UK) Ltd. One of the key priorities of the Automotive Industrial Partnership is to support supply chain employers to gain access to industry standard technical, leadership and management programmes to upskill their existing workforce and develop new recruits. The results have been impressive. So far 111 people have completed the Advanced Problem Solving training with 21 of the 23 companies taking part being SMEs from the supply chain delivering almost £4m in quality cost savings for their businesses to date. Mr Parsons said while the training was designed to help companies find solutions to their own problems, sharing experiences and applying analysis had also made a significant difference, bringing benefits to the wider sector. “Problem solving methodologies in general follow a similar format, commencing with a clear problem definition before narrowing down across a number of stages to enable the true problem root cause to be effectively counter-measured. “Often, these methodologies do not contain any high-level tools to aid complex data analysis, hence there is a requirement to provide training to add these additional tools into the overall methodology being used. “The Advanced Problem Solving programme takes the tools from Six-Sigma (a well known approach utilised by the manufacturing sector to reduce productivity defects) and embeds them into whichever problem solving methodology is being applied.” Training is delivered by specialist provider Capella Associates. Two levels of Advanced Problem Solving are available, ‘Green Belt’ and ‘Black Belt’. The training is a mixture of classroom-based, on-site training, presentations and reviews completed over a 10-month period. Mr Parsons added: “The key benefit of the programmes at both Black Belt and Green Belt levels are in the completion of a real project – following a project based methodology not only ensures that the learning is embedded and evidenced, but also that a real business benefit is delivered. “It provides us with a common standard and suite of tools for advanced problem solving to increase the industry’s capability to respond correctly and swiftly to complex problems in the workplace. “There is currently no single qualification recognised across the Automotive industry for higher level problem solving. These programmes therefore address an industry need for transferrable, in depth problem solving skills.” Ian Harpham, manufacturing director of electronics manufacturer Pektron, who supply the automotive industry, said the learning applied in his company from three employees on the Green Belt course had delivered substantial savings. “We were able to solve a long-running testing problem on one of our components, saving us thousands of pounds so the training has more than paid for itself,” said Mr Harpham. “It has provided a new qualification for employees and a new suite of tools to solve difficult problems. “Everybody had an opinion on this one particular testing problem and everyone was wrong – we would not have got to the point of resolution without the training – it removed the blinkers from our thinking. “We are involved in testing 300-400 different products – if we apply the same thinking to all of them as we have done to one then there is a real opportunity to make even more substantial savings.” The employers driving the Automotive Industrial Partnership include Bentley, BMW, Ford, GKN, Honda, Jaguar Land Rover, Nissan, Toyota and Vauxhall. Employer led skills organisation Semta, industry trade association the SMMT and the Department for Business, Innovation and Skills and UKCES are also supporting the Partnership. For more information about the Automotive Industrial Partnership go to automotiveip.co.uk or call 0845 6439001. Also view case studies for supply chain employers Pektron and Stadco, who have benefited from the Advanced Problem Solving programme. Notes to Editors The Automotive Industrial Partnership was formed following a successful bid for Employer Ownership Pilot (EOP) funding, a £340m competitive fund that invited employers to tell government how they would use public investment, alongside their own, to invest in the skills of their current and future workforce in order to grow our economy. The Automotive Industrial Partnership was instigated by the Automotive Council to help deliver the government’s automotive industrial strategy. Set up in 2009, the Automotive Council is a platform for the industry and government to work together to drive the sector to global leadership. The project is jointly funded by the Department for Business, Innovation and Skills (BIS) and the Department for Education, and is administered by the Skills Funding Agency. It was developed in conjunction with UKCES. The government investment for the Automotive Industrial Partnership totals £11.3m. This is matched by the auto sector with £19.1m of its own resources (£16.4m in kind and £2.8m cash). Semta Semta (Science, Engineering and Manufacturing Technologies Alliance) is a not-for-profit organisation at the epicentre of skills – helping to create the next generation of engineers and ensure that the UK continues to play a leading role in utilising and enhancing its unrivalled reputation for technological excellence. SMMT The Society of Motor Manufacturers and Traders (SMMT) is one of the largest and most influential trade associations in the UK. It supports the interests of the UK automotive industry at home and abroad, promoting a united position to government, stakeholders and the media. Industry Forum Is a manufacturing improvement specialist, bringing together a world-class combination of expertise, insight and best practice to the automotive sector.