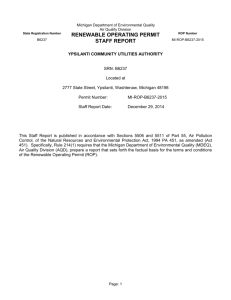

B6237 Final 3-17

advertisement